Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Loom Checker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

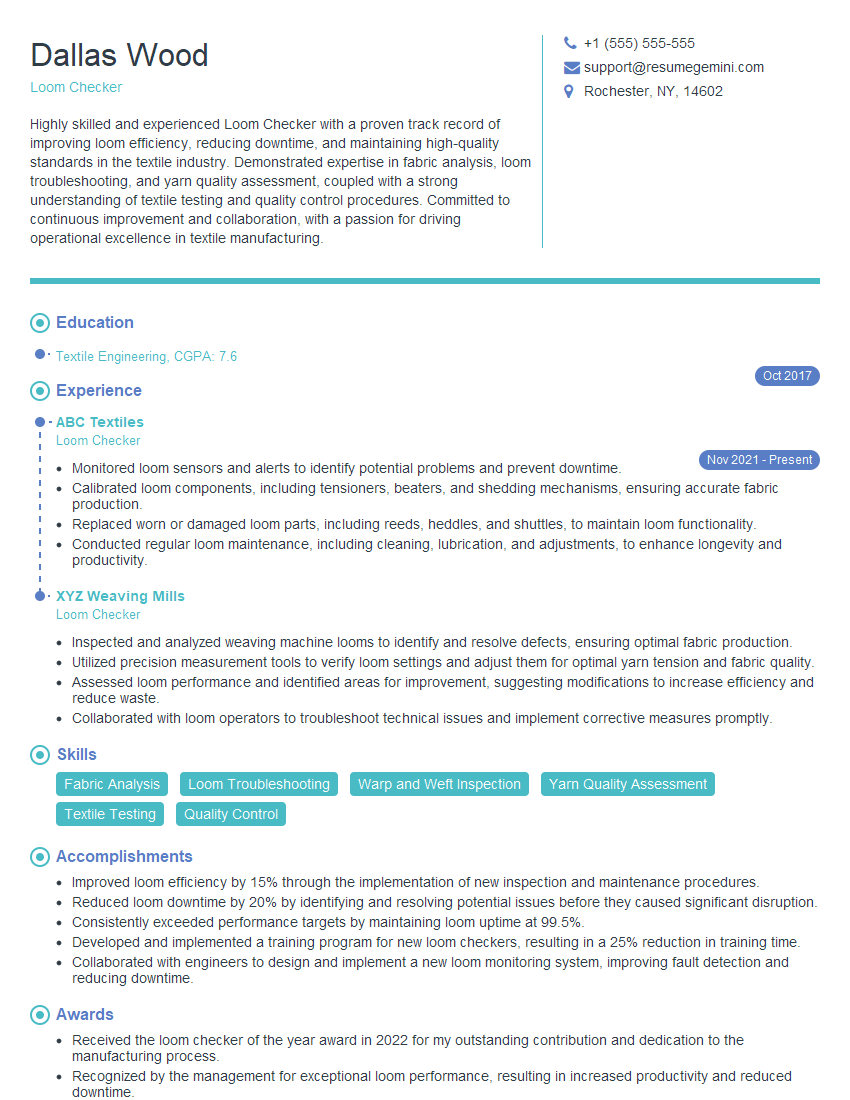

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loom Checker

1. Describe the key responsibilities of a Loom Checker.

As a Loom Checker, my primary responsibilities would include:

- Inspecting looms for defects and ensuring they meet quality standards.

- Adjusting and calibrating looms to optimize performance.

- Identifying and troubleshooting loom malfunctions and breakdowns.

- Maintaining detailed records of loom inspections, adjustments, and repairs.

- Collaborating with production and maintenance teams to ensure efficient loom operation.

2. Explain the different types of looms and their respective advantages and disadvantages.

- Air-Jet Looms:

- Advantages: High speed, reduced noise, improved fabric quality.

- Disadvantages: Expensive to maintain, susceptible to yarn breakages.

- Water-Jet Looms:

- Advantages: High production rates, suitable for a wide range of yarns.

- Disadvantages: High water consumption, increased noise levels.

- Rapier Looms:

- Advantages: Gentle on yarns, versatile for different fabrics.

- Disadvantages: Slower speed than other looms, higher maintenance requirements.

- Jacquard Looms:

- Advantages: Complex pattern weaving, suitable for intricate designs.

- Disadvantages: Slower speed, more labor-intensive operation.

3. Discuss the importance of loom maintenance and how you prioritize maintenance tasks.

Regular loom maintenance is crucial for ensuring optimal performance, preventing breakdowns, and extending the lifespan of looms. I prioritize maintenance tasks based on:

- Frequency: Tasks that require frequent attention, such as cleaning and lubrication.

- Criticality: Tasks that have a significant impact on loom operation, such as adjusting tension or troubleshooting malfunctions.

- Urgency: Tasks that need immediate attention to prevent loom damage or downtime.

- Safety: Tasks that are essential for maintaining a safe working environment around looms.

4. Describe the quality control processes you follow when inspecting looms and fabrics.

My quality control processes include:

- Visual Inspection: Checking for defects in loom components, fabric appearance, and yarn quality.

- Dimensional Inspection: Measuring fabric dimensions to ensure they meet specifications.

- Tension Testing: Verifying yarn tension to prevent fabric defects and ensure optimal loom performance.

- Color Matching: Ensuring that fabric colors match customer specifications and industry standards.

- Reporting: Documenting inspection findings and recommending corrective actions if necessary.

5. What is the difference between a warp and a weft?

In weaving, the warp refers to the longitudinal yarns that run parallel to the loom’s length. They are typically stronger and provide structural support to the fabric. The weft, on the other hand, refers to the transverse yarns that are interlaced with the warp yarns to create the fabric’s pattern and texture.

6. How do you troubleshoot common loom problems, such as yarn breakages or fabric defects?

To troubleshoot common loom problems:

- Identify the problem: Observe the loom’s operation and fabric output to pinpoint the issue.

- Check loom settings: Verify that tension, speed, and temperature settings are correct.

- Inspect loom components: Examine gears, belts, and other components for wear or damage.

- Test yarn quality: Check for yarn breaks, unevenness, or contamination.

- Adjust settings or replace components: Make necessary adjustments or repairs to resolve the issue.

7. Explain the importance of maintaining proper tension in the loom.

Proper tension is crucial for loom operation and fabric quality because:

- Yarn breakage reduction: Adequate tension prevents yarns from breaking during weaving.

- Fabric quality improvement: Even tension ensures consistent fabric density and texture.

- Reduced loom wear: Balanced tension prevents excessive strain on loom components.

- Increased productivity: Maintaining proper tension reduces downtime caused by yarn breakages or fabric defects.

8. Describe the different types of sensors used in modern looms and explain their functions.

Modern looms utilize various sensors, including:

- Reed Sensors: Monitor loom speed and detect yarn breakages.

- Warp Tension Sensors: Measure warp yarn tension and adjust it accordingly.

- Fabric Tension Sensors: Ensure proper fabric tension throughout the weaving process.

- Temperature Sensors: Monitor loom temperature and trigger safety mechanisms in case of overheating.

- Vibration Sensors: Detect excessive vibration and indicate mechanical issues.

9. Discuss the environmental impact of weaving and how you promote sustainable practices in your work.

Weaving has environmental impacts, such as energy consumption, water usage, and waste generation. As a Loom Checker, I prioritize sustainable practices:

- Energy conservation: Optimizing loom settings and using energy-efficient lighting.

- Water reduction: Minimizing water usage in cleaning and maintenance processes.

- Waste reduction: Recycling loom components and fabric scraps, reducing waste sent to landfills.

- Chemical reduction: Using eco-friendly cleaning agents and minimizing chemical waste.

10. Describe a situation where you successfully resolved a complex loom issue.

In a previous role, I encountered a persistent warp yarn breakage issue on a high-speed loom. After careful examination, I discovered a slight misalignment in the warp beam. I adjusted the beam alignment, recalibrated the loom settings, and performed tension tests. The issue resolved, significantly improving yarn quality and reducing downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loom Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loom Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Loom Checkers play a crucial role in the textile industry, ensuring the quality and accuracy of woven fabrics. Their key responsibilities include:

1. Fabric Inspection

Thoroughly inspect woven fabrics for defects, such as broken threads, uneven weaving, and color variations. Utilize specialized equipment like magnifying glasses and light tables to identify and document any imperfections.

2. Quality Control

Monitor and maintain quality standards throughout the production process. Implement quality control measures to ensure that fabrics meet specifications and customer requirements.

3. Machine Maintenance

Perform preventive maintenance on looms and related equipment. Clean and lubricate machinery, adjust settings, and identify potential issues before they escalate into larger problems.

4. Troubleshooting

Troubleshoot and resolve loom-related issues, such as fabric defects, machine malfunctions, and yarn breaks. Collaborate with other departments to identify root causes and implement corrective actions.

5. Training

Train and supervise junior loom checkers. Provide guidance and support to ensure they adhere to company policies and quality standards.

Interview Tips

To ace an interview for a Loom Checker position, consider these tips:

1. Prepare for Technical Questions

Be prepared for questions related to fabric inspection techniques, quality control processes, and loom maintenance procedures. Review industry-specific terminology and familiarize yourself with common loom models.

2. Highlight Attention to Detail

Emphasize your meticulous attention to detail and ability to identify even the smallest fabric defects. Provide examples of how you have consistently maintained high quality standards in previous roles.

3. Demonstrate Troubleshooting Skills

Discuss your troubleshooting experience and how you have successfully resolved loom-related issues in the past. Use the STAR method (Situation, Task, Action, Result) to provide specific examples.

4. Show Willingness to Learn

Express your eagerness to learn new technologies and industry best practices. Highlight your commitment to continuous improvement and staying abreast of advancements in the textile field.

5. Adapt Example Outline to Specific Questions

When answering interview questions, tailor your Example Outline to match the specific requirements of the position. For instance, if asked about your troubleshooting approach, you could use the following outline:

- Situation: Briefly describe the situation where you encountered a loom issue.

- Task: Explain your role in troubleshooting the problem.

- Action: Describe the steps you took to identify and resolve the issue.

- Result: State the outcome of your troubleshooting efforts, quantifying your impact if possible.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Loom Checker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!