Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Loom Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

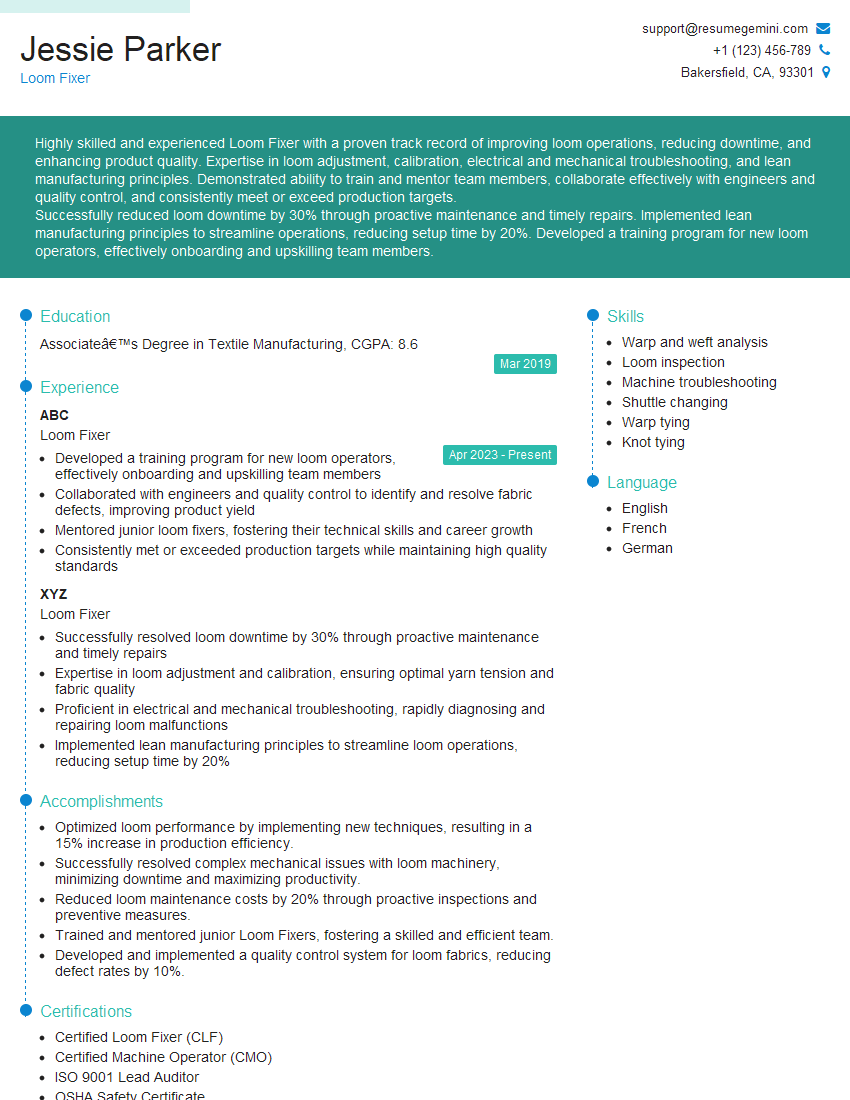

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loom Fixer

1. What is the process of warp preparation for weaving?

The process of warp preparation for weaving involves several steps to prepare the warp yarns for weaving. Here’s an overview of the process:

- Creeling: Empty bobbins are placed on a creel, and the warp yarns are wound onto these bobbins from cones or hanks.

- Warping: The creel bobbins are mounted on a warping machine, and the warp yarns are drawn through a series of rollers and guides to create a continuous warp sheet.

- Sizing: The warp sheet is coated with a sizing agent to strengthen the yarns and reduce hairiness, which improves weaving efficiency.

- Drawing-in: The warp yarns are drawn through the heddles and reed of the loom, which determines the pattern and structure of the woven fabric.

2. Explain the different types of looms and their applications.

Shuttle Loom:

- Uses a shuttle to pass the weft yarn through the shed.

- Suitable for weaving simple fabrics like canvas, denim, and shirting.

Projectile Loom:

- Fires a projectile carrying the weft yarn across the shed.

- Faster than shuttle looms, used for weaving heavier fabrics like upholstery and carpets.

Rapier Loom:

- Uses a gripper mechanism to carry the weft yarn across the shed.

- Versatile, can weave a wide range of fabrics, including delicate and intricate designs.

Water Jet Loom:

- Uses a water jet to propel the weft yarn through the shed.

- Very fast, used for weaving high-volume, lightweight fabrics like geotextiles and medical textiles.

Air Jet Loom:

- Uses a jet of air to propel the weft yarn through the shed.

- Even faster than water jet looms, used for weaving high-performance fabrics like airbags and parachutes.

3. What are the common types of defects found in woven fabrics and how can they be prevented?

Common Defects:

- Broken Ends: Missing warp or weft yarns.

- Slubs: Thick places in the yarn.

- Holes: Missing areas of fabric.

- Bowing: Fabric is not flat.

- Selvage Defects: Irregularities at the edges of the fabric.

Prevention Measures:

- Proper yarn preparation and maintenance.

- Regular loom maintenance and calibration.

- Careful handling of fabric during weaving and finishing.

- Monitoring and controlling environmental conditions.

- Implementing quality control measures.

4. Describe the process of fabric finishing and its importance.

Fabric finishing is a series of processes applied to woven fabrics to enhance their properties and appearance. Key steps include:

- Scouring and Bleaching: Removing impurities and whitening the fabric.

- Dyeing and Printing: Adding color and patterns.

- Softening and Anti-Wrinkling: Improving fabric handle and reducing creases.

- Flame Retardancy and Water Resistance: Enhancing fabric functionality.

Finishing is crucial for improving fabric quality, durability, and marketability.

5. What are the safety precautions that need to be taken while operating a loom?

- Wear appropriate protective clothing and safety glasses.

- Keep the work area clean and free of tripping hazards.

- Inspect the loom regularly for any potential issues.

- Do not operate the loom unless you are trained and authorized.

- Follow all established safety protocols and procedures.

6. What are the key maintenance tasks for a loom and how often should they be performed?

- Daily: Cleaning, lubrication, checking for loose parts.

- Weekly: Inspecting electrical connections, adjusting tension settings.

- Monthly: Calibrating sensors, replacing worn parts.

- Annually: Overhauling major components, conducting a thorough inspection.

7. How do you troubleshoot common loom problems, such as broken warp or weft yarns?

Broken Warp Yarn:

- Check for yarn breakage at the creel or draw-in area.

- Inspect the warp beam for any damage.

- Adjust tension settings as needed.

Broken Weft Yarn:

- Check for yarn breakage at the shuttle, projectile, or gripper.

- Inspect the weft yarn supply for any tangles or knots.

- Adjust timing and tension settings.

8. What are the latest advancements in loom technology and how do they improve weaving efficiency?

- Digital Jacquards: Offer increased pattern flexibility and design capabilities.

- Electronic Warp Stop Motion: Detects broken warp yarns instantly, reducing downtime.

- Automated Tension Control: Maintains optimal tension throughout the weaving process.

- Data Monitoring Systems: Provide real-time data on loom performance, allowing for proactive maintenance.

9. How do you stay updated with the latest industry best practices and technological developments in weaving?

- Attend industry conferences and workshops.

- Read technical journals and online resources.

- Connect with other loom fixers and textile professionals.

- Participate in training programs offered by equipment manufacturers.

10. What are your strengths and weaknesses as a Loom Fixer?

Strengths:

- Strong technical knowledge and experience in loom maintenance and repair.

- Excellent troubleshooting and problem-solving skills.

- Proactive and detail-oriented, with a focus on preventing downtime.

Weaknesses:

- Limited experience with the latest digital loom technologies.

- Working independently for extended periods can sometimes be challenging.

I am actively working on addressing these weaknesses through training and collaboration with colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loom Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loom Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Loom fixers are responsible for maintaining and repairing looms, the machines that weave fabric. They work with a variety of looms, including mechanical, electronic, and computerized looms. Their key responsibilities include:

1. Troubleshooting and repairing looms

Loom fixers must be able to quickly troubleshoot loom problems and make necessary repairs.

- Identifying problems with looms, such as broken threads, faulty sensors, or mechanical issues

- Making repairs to looms, such as replacing parts, adjusting settings, or lubricating moving parts

2. Preventive maintenance

Loom fixers also perform preventive maintenance on looms to keep them running smoothly and prevent costly breakdowns.

- Inspecting looms for wear and tear

- Cleaning and lubricating looms

- Replacing worn parts

3. Training new employees

Loom fixers may also be responsible for training new employees on how to operate and maintain looms.

- Instructing new employees on the basics of loom operation

- Teaching new employees how to troubleshoot and repair looms

- Evaluating new employees’ progress and providing feedback

4. Quality control

Loom fixers may also be involved in quality control, inspecting fabric for defects and ensuring that it meets customer specifications.

- Inspecting fabric for defects, such as broken threads, holes, or uneven weave

- Rejecting fabric that does not meet customer specifications

- Working with weavers to identify and correct problems that are causing defects

Interview Tips

To ace an interview for a loom fixer position, it is important to be prepared and to highlight your skills and experience. Here are some tips:

1. Research the company and the position

Take some time to research the company you are interviewing with, as well as the specific loom fixer position. This will help you to understand the company’s culture and values, as well as the specific skills and experience that they are looking for.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Talk to people in your network who work in the industry to get their insights.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions. The STAR method stands for Situation, Task, Action, Result.

- When answering questions, be specific and provide examples from your own experience.

- Quantify your results whenever possible. For example, instead of saying “I increased productivity,” say “I increased productivity by 15%.”

3. Be prepared to talk about your loom fixing experience

The interviewer will want to know about your experience fixing looms. Be prepared to talk about the specific types of looms you have worked on, the problems you have solved, and the results you have achieved.

- Highlight your skills in troubleshooting and repairing looms.

- Discuss your experience with preventive maintenance and quality control.

- If you have any experience training new employees, be sure to mention it.

4. Be prepared to answer questions about your safety knowledge

As a loom fixer, you will be responsible for working with heavy machinery. The interviewer will want to know about your safety knowledge and practices.

- Discuss your knowledge of OSHA regulations.

- Describe your experience with lockout/tagout procedures.

- Explain how you would handle a safety hazard.

5. Be prepared to talk about your availability and salary expectations

The interviewer will want to know about your availability and salary expectations. Be prepared to answer these questions honestly and confidently.

- Be honest about your availability.

- Research industry salaries to get an idea of what you should expect.

- Be prepared to negotiate your salary.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Loom Fixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!