Are you gearing up for a career in Loom Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Loom Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

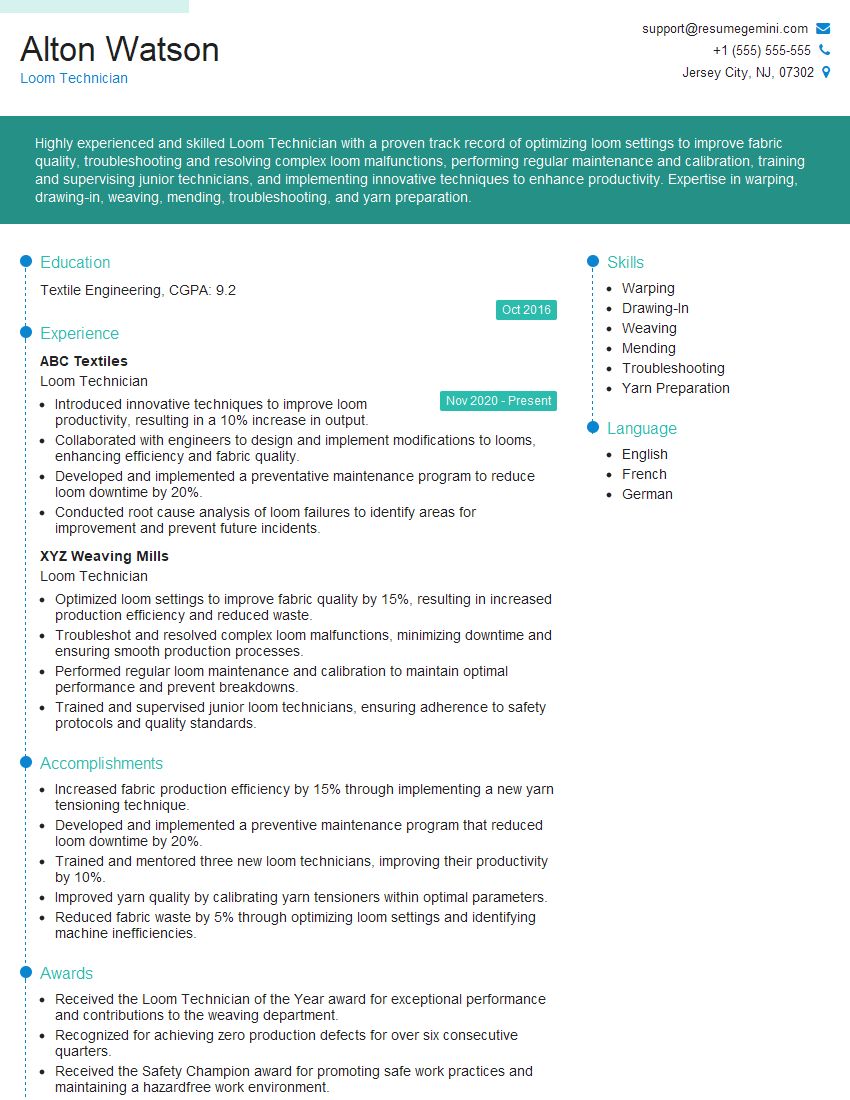

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loom Technician

1. Explain the different types of looms you have worked with and their key features?

- Describe the different types of looms, such as power loom, hand loom, and shuttle loom.

- Explain the key features of each loom type, including its speed, capacity, and versatility.

2. Describe the process of setting up a loom for a specific fabric?

Preparing the Warp

- Calculating the warp length and winding it onto the warp beam.

- Drawing the warp ends through the reed and heddles.

Preparing the Weft

- Selecting the appropriate weft yarn and winding it onto the shuttle or bobbin.

- Adjusting the weft tension to ensure even weaving.

3. How do you troubleshoot common loom problems, such as yarn breakage, shedding errors, and fabric defects?

- Identify the source of the problem by observing the loom’s operation and the fabric produced.

- Apply specific troubleshooting techniques to rectify the issue, such as adjusting tension, replacing worn parts, or recalibrating sensors.

4. How do you ensure the quality of the woven fabric?

- Regularly inspect the fabric for defects, such as uneven weaving, yarn breakage, or color variations.

- Calibrate and maintain the loom to ensure optimal performance and fabric quality.

5. How do you optimize loom efficiency and productivity?

- Properly maintain the loom to minimize downtime and ensure smooth operation.

- Optimize loom settings, such as speed, tension, and shedding, to maximize fabric output.

6. What are the safety precautions you follow while operating a loom?

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep the work area clean and free of tripping hazards.

7. Describe your experience in working with different types of yarns and their properties?

- Explain the characteristics of various yarn types, such as cotton, wool, silk, and synthetic fibers.

- Describe how the properties of different yarns affect the weaving process and fabric quality.

8. How do you stay updated with the latest developments in the weaving industry?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

9. What are your career goals and how do you see this role contributing to your professional development?

- Express your interest in the loom technician role and its alignment with your career aspirations.

- Explain how the opportunity will allow you to enhance your skills, gain experience, and contribute to the organization’s success.

10. Do you have any questions for me about the role or the company?

- Ask thoughtful questions that demonstrate your interest and enthusiasm for the position.

- Inquire about the company’s culture, growth opportunities, and commitment to safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loom Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loom Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Loom Technicians are responsible for the operation, maintenance, and repair of weaving looms in a textile manufacturing setting. They ensure that the looms are running efficiently and producing high-quality fabrics.

1. Loom Operation

Set up, operate, and monitor weaving looms to produce fabrics according to specifications.

- Adjust loom settings, such as yarn tension and weaving speed, to optimize fabric quality.

- Inspect fabric output for defects and adjust loom parameters as needed.

2. Loom Maintenance

Inspect and maintain looms regularly to prevent breakdowns and ensure optimal performance.

- Clean and lubricate loom components to minimize wear and tear.

- Identify and replace worn or damaged loom parts, such as shuttle boxes and warp beams.

3. Troubleshooting and Repair

Diagnose and repair loom malfunctions and breakdowns promptly to minimize downtime.

- Use diagnostic tools and techniques to identify the source of problems.

- Perform repairs, such as replacing electrical components or adjusting mechanical parts.

4. Quality Control

Monitor fabric quality and make adjustments to loom settings as needed to meet quality standards.

- Inspect fabric for defects, such as broken threads or uneven weaving.

- Make adjustments to loom parameters to correct any quality issues.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help candidates ace their Loom Technician interview:

1. Research the Company and Position

Familiarize yourself with the company’s business, products, and culture. Understand the specific requirements and responsibilities of the Loom Technician role.

- Visit the company’s website and social media pages.

- Read industry-related articles and publications.

2. Highlight Relevant Skills and Experience

Showcase your technical skills, problem-solving abilities, and experience in operating and maintaining looms. Quantify your accomplishments and provide specific examples.

- Emphasize your ability to identify and resolve loom malfunctions.

- Demonstrate your understanding of fabric quality control and maintenance procedures.

3. Practice Common Interview Questions

Prepare for common interview questions such as:

- Tell us about your experience in operating and maintaining looms.

- Describe a time when you successfully diagnosed and repaired a loom malfunction.

- How do you ensure the production of high-quality fabrics?

4. Prepare Questions for the Interviewer

Asking thoughtful questions not only shows your interest but also allows you to gather more information about the company and the role.

- Inquire about the company’s production goals and quality standards.

- Ask about opportunities for professional development within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Loom Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Loom Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.