Feeling lost in a sea of interview questions? Landed that dream interview for Loop Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Loop Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

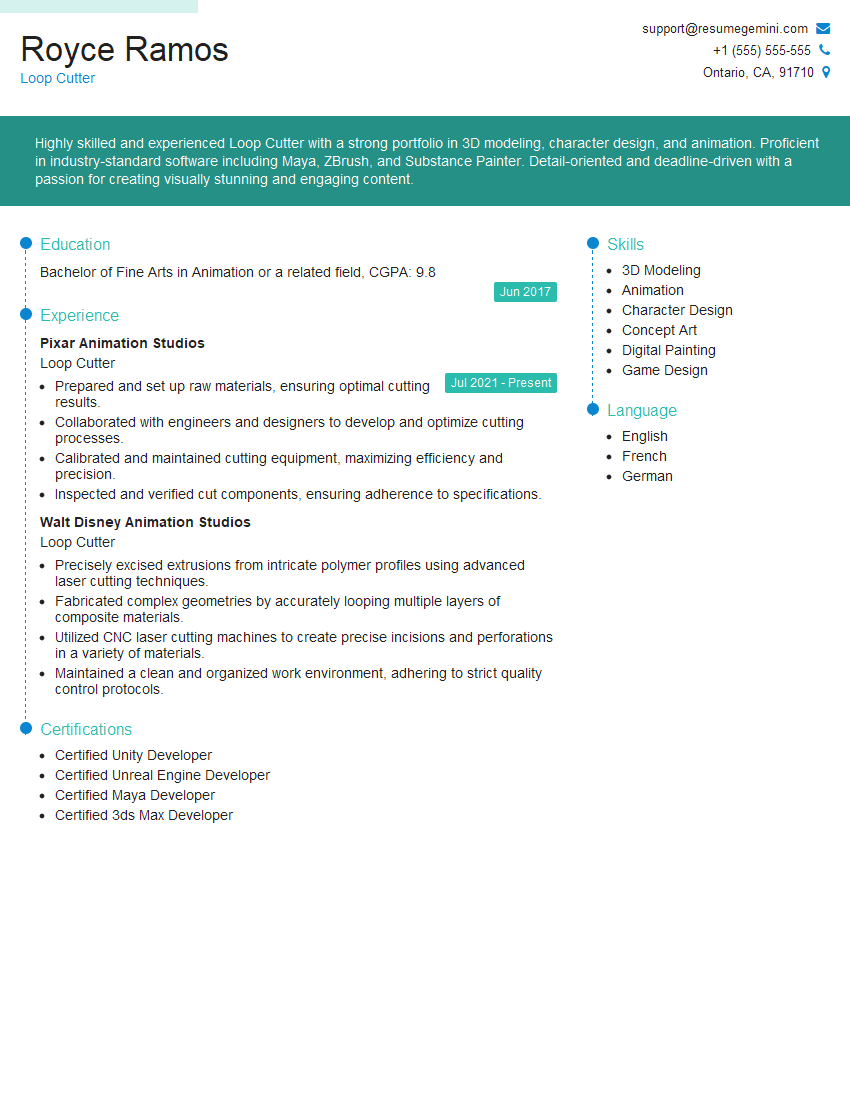

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loop Cutter

1. Explain the process of loop cutting in detail.

Loop cutting is a technique used in 3D modeling to create clean and consistent topology by cutting loops of edges around the model’s surface. The process involves identifying and connecting points on the mesh where the topology needs to be refined, creating new loops of edges that divide the surface into smaller, evenly distributed polygons.

- Identify key features and areas of the model that require additional detail or refinement.

- Select and connect points on the mesh that define the desired loop, ensuring that the loop follows the natural flow of the model’s surface.

- Use modeling tools to cut the new loop of edges, dividing the surface into smaller polygons.

- Repeat the process to create additional loops as needed, refining the topology and creating a more detailed and consistent mesh.

2. Describe the advantages and disadvantages of using loop cutting.

Advantages

- Improved topology: Loop cutting creates a more consistent and organized topology, which makes the model easier to work with and edit in the future.

- Increased flexibility: The resulting topology allows for greater flexibility and control over the model’s shape and form, enabling more precise sculpting and animation.

- Better deformation: The evenly distributed polygons created by loop cutting improve the model’s deformation behavior, resulting in more natural and realistic animations.

Disadvantages

- Can be time-consuming: Loop cutting can be a time-intensive process, especially for complex models with numerous surfaces.

- Requires careful planning: Improper loop cutting can lead to topology issues and make the model difficult to work with. Careful planning and consideration are essential to ensure optimal results.

3. How do you determine the optimal loop density for a given model?

The optimal loop density for a model depends on the intended use and the level of detail required. Here’s how to determine it:

- Consider the model’s purpose: If the model is intended for animation or high-resolution rendering, a denser loop density will be necessary to support finer details and smooth deformations.

- Analyze the model’s geometry: Examine the model’s shape and identify areas that require more detail or better flow. These areas may require a higher loop density.

- Test and iterate: Experiment with different loop densities and observe the results in the viewport. Adjust the density until the desired level of detail and surface quality is achieved.

4. Explain how you handle complex geometry when loop cutting.

Handling complex geometry requires careful planning and attention to detail when loop cutting. Here’s how to approach it:

- Identify natural flow: Analyze the complex geometry to understand its natural flow and curvature. Loop cutting should follow these curves to maintain the integrity of the surface.

- Divide into sections: Break down the complex geometry into smaller, manageable sections. Focus on loop cutting one section at a time to avoid overwhelming the topology.

- Use support loops: Create additional loops that support and follow the complex curves. These support loops help maintain the smoothness and continuity of the topology.

5. Discuss the relationship between loop cutting and UV mapping.

Loop cutting plays a crucial role in UV mapping as it defines the seams and boundaries of UV shells. Here’s how they are related:

- Seamless UVs: Properly placed loop cuts create natural seams that allow for seamless UV unwrapping. This ensures that the texture flows smoothly across the model’s surface.

- Optimal UV layout: Loop cuts can be used to create UV shells that are optimized for texture space utilization. This minimizes stretching and distortion, resulting in a more efficient and aesthetically pleasing UV layout.

6. How do you handle edge flow when loop cutting?

Maintaining proper edge flow is essential for creating a clean and workable mesh. Here’s how to manage edge flow during loop cutting:

- Follow natural flow: Loop cuts should follow the natural flow of the model’s surface, avoiding sharp corners or unnatural breaks in the edge flow.

- Control edge density: Use loop cuts to refine edge density in areas that require more detail, while maintaining a consistent flow in less detailed areas.

- Avoid intersecting loops: Ensure that loop cuts do not intersect, as this can create topological issues and disrupt the edge flow.

7. Explain the difference between edge and face loops.

Edge loops and face loops are two types of loops used in 3D modeling:

Edge loops

- Consist of a continuous series of connected edges.

- Define the flow of geometry and create sharp creases or smooth curves.

- Used for refining details, creating natural folds, or defining muscle groups.

Face loops

- Consist of a series of connected faces that form a closed loop.

- Define the boundaries of UV shells and help control texture mapping.

- Used for organizing and managing UV space, ensuring efficient texture utilization.

8. Describe the tools and techniques you use for loop cutting.

Various tools and techniques are used for loop cutting:

Tools

- Loop Cut Tool: Found in most 3D modeling software, this tool allows users to interactively create loops by defining the number and placement of cuts.

- Knife Tool: A versatile tool that can be used to create freehand cuts, including loop cuts, by defining the path of the cut on the model’s surface.

Techniques

- Edge Looping: Cutting loops around the edges of the model to refine details or create creases.

- Grid Cutting: Creating orthogonal loops across the surface to create a regular pattern of polygons.

- Radial Cutting: Cutting loops in a circular or radial pattern around specific points or axes.

9. How do you optimize your loop cutting workflow?

Optimizing the loop cutting workflow involves several strategies:

- Plan ahead: Analyze the model and identify areas that require loop cuts before starting the process.

- Use shortcuts and macros: Utilize software-specific shortcuts and macros to speed up loop cutting and streamline the workflow.

- Work non-destructively: Use tools that allow for non-destructive loop cutting, such as the Knife Tool with the “Incremental” option.

- Test and refine: Regularly inspect the model and adjust loop cuts as needed to ensure the desired topology and surface quality.

10. Share an example of a complex model where loop cutting was crucial for achieving the desired result.

In a recent project, I was tasked with modeling a highly detailed character for a video game. The character had intricate muscle groups, clothing, and accessories that required precise loop cutting to achieve the desired level of realism.

- To define the contours of the muscles, I used edge loops to create sharp creases and smooth curves.

- For the clothing, I employed face loops to control the UV mapping and ensure seamless texture transitions.

- The accessories, such as belts and buckles, were modeled using a combination of edge and face loops to achieve both detail and proper edge flow.

By carefully planning and executing the loop cutting process, I was able to create a high-quality model that met the requirements of the project and brought the character to life with impressive detail.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loop Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loop Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Loop Cutters play a crucial role in the garment manufacturing industry, ensuring precise cutting of fabric for the production of garments.

1. Fabric Preparation

Prepare fabric rolls by inspecting, measuring, and spreading them on the cutting table.

- Verify fabric specifications and ensure quality control.

- Calculate fabric requirements and mark cutting lines.

2. Loop/Spread Machine Operation

Operate automated loop/spread machines to lay out fabric layers.

- Set up and adjust machine parameters for optimal fabric spreading.

- Monitor and troubleshoot machine operations to ensure efficient production.

3. Cutting

Utilize cutting machines to cut fabric layers precisely.

- Program cutting patterns and optimize fabric utilization.

- Inspect cut pieces for accuracy and quality.

4. Material Handling

Handle and transport fabric rolls, cut pieces, and waste material.

- Maintain a clean and organized work area for efficient production.

- Adhere to safety protocols and ergonomic principles.

Interview Tips

Preparing thoroughly for a Loop Cutter interview can significantly increase your chances of success. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends.

- Visit the company’s website and read industry publications.

- Connect with current or former employees on LinkedIn.

2. Practice Common Interview Questions

Review common interview questions and prepare thoughtful answers.

- Why are you interested in working as a Loop Cutter?

- Describe your experience with loop/spread machines.

3. Highlight Relevant Skills and Experience

Emphasize your proficiency in fabric handling, cutting techniques, and quality control.

- Quantify your accomplishments using specific metrics.

- Use examples from your previous work experience to demonstrate your skills.

4. Prepare Thoughtful Questions

Asking insightful questions at the end of the interview shows your engagement and interest.

- Inquire about the company’s growth plans and innovation initiatives.

- Ask about opportunities for professional development.

5. Dress Professionally and Maintain a Positive Attitude

A professional appearance and a positive demeanor can make a strong impression.

- Wear appropriate attire and arrive punctually.

- Be enthusiastic, friendly, and respectful throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Loop Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!