Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Loop Tacker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

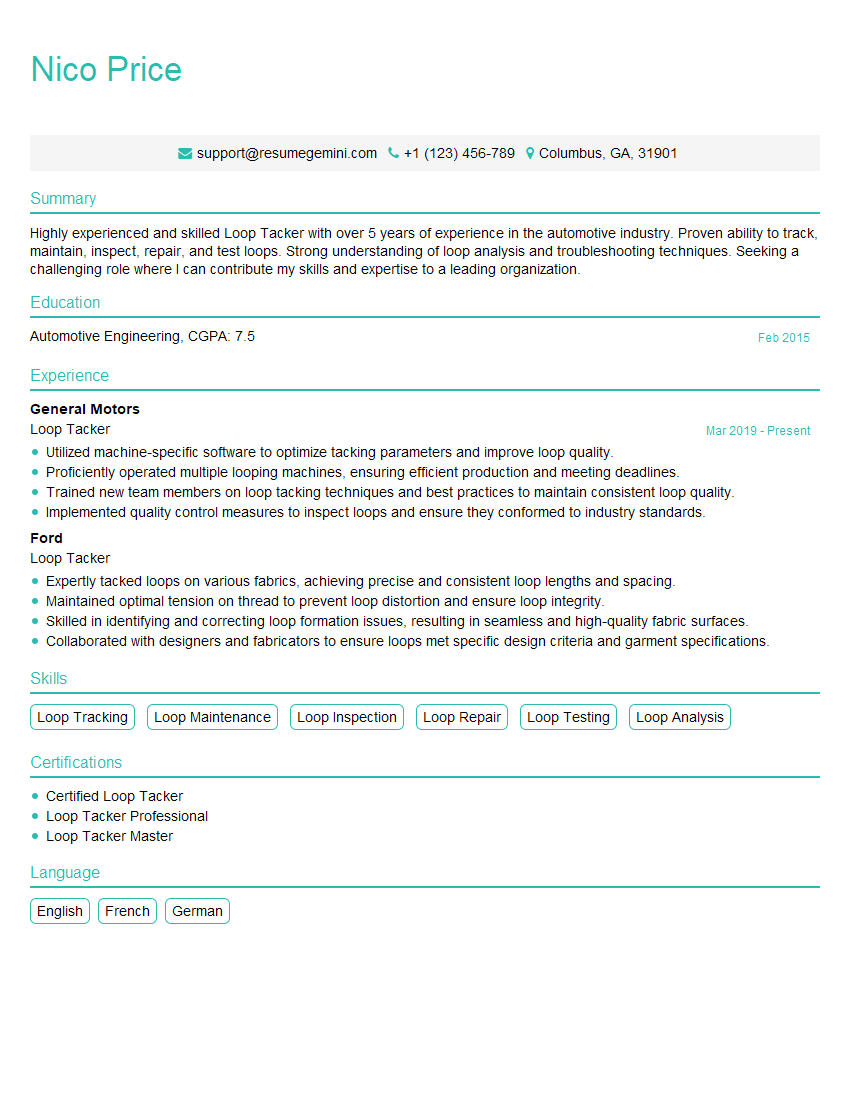

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Loop Tacker

1. Explain the process of looped tacking and its importance in the textile industry?

Looped tacking is a specialized sewing technique used to join two pieces of fabric with a series of interlocking loops. This method ensures a strong and durable seam that can withstand high levels of stress and strain.

- Importance in the textile industry:

- Creating strong and secure seams for garments, especially in areas subject to high tension, such as waistbands, armholes, and shoulder seams.

- Providing reinforcement to prevent seam slippage or tearing in critical areas.

- Used in various garment constructions, including tailored suits, formal dresses, and outdoor gear.

- Enhancing the durability and longevity of garments, reducing the risk of seam failure.

2. What are the different types of looped tacking stitches and when are they used?

Multiple Zigzag Stitch:

- Consists of a series of multiple zigzag stitches overlapping each other.

- Suitable for heavy-duty applications where maximum strength is required, such as in jeans, workwear, and tents.

Diamond Tack Stitch:

- Forms a diamond-shaped pattern with interlocking loops.

- Used in fine fabrics, such as silk or lace, where strength and aesthetics are important.

Triple Lockstitch:

- Creates three parallel rows of interlocking loops.

- Provides excellent strength and durability, making it ideal for garments that need to withstand frequent laundering, such as uniforms.

Catchstitch:

- A simple stitch that loops over the edge of one fabric and into the other.

- Used for attaching linings or interfacing to garments.

3. What are the key factors to consider when selecting a looped tacking machine?

When selecting a looped tacking machine, several key factors should be considered to ensure optimal performance and efficiency.

- Stitch type: Different machines specialize in specific stitch types, so choose the one that suits your production needs.

- Stitch length and width: Determine the appropriate stitch settings based on fabric weight and seam requirements.

- Tacking speed: Consider the required production volume and choose a machine that can meet your speed demands.

- Automation capabilities: Some machines offer automated features, such as thread trimming and feeding, which can increase efficiency.

- Maintenance and accessibility: Choose a machine that is easy to maintain and has readily available spare parts.

4. How do you troubleshoot common looped tacking problems, such as skipped stitches or thread breakage?

Troubleshooting common looped tacking problems requires a systematic approach to identify and resolve the issue.

- Skipped stitches:

- Check thread tension and adjust it appropriately.

- Examine the needle and replace it if bent or damaged.

- Clean the bobbin and needle plate to remove any lint or debris.

- Thread breakage:

- Inspect the thread for any nicks or weak spots.

- Check the threading path for any obstructions or sharp edges.

- Ensure the thread is properly lubricated to prevent friction.

5. What safety precautions should be taken when operating a looped tacking machine?

- Wear appropriate safety gear, including safety glasses and protective clothing.

- Keep hands away from moving parts, such as the needle and thread guide.

- Ensure the machine is properly grounded to prevent electrical shock.

- Turn off the power and unplug the machine before performing any maintenance or repairs.

- Follow the manufacturer’s instructions for safe operation and maintenance.

6. How do you maintain a looped tacking machine to ensure optimal performance?

- Regular cleaning: Remove lint, dust, and thread clippings from the machine regularly.

- Oil and lubrication: Follow the manufacturer’s instructions for oiling and lubricating moving parts.

- Needle replacement: Inspect the needle regularly and replace it when bent or damaged.

- Tension adjustment: Ensure proper thread tension to prevent skipped stitches or thread breakage.

- Calibration: Periodically calibrate the machine according to the manufacturer’s specifications.

7. Describe the role of a Loop Tacker in the garment production process.

- Responsible for operating looped tacking machines to reinforce seams and enhance durability.

- Works closely with other production team members, such as seamstresses and cutters.

- Ensures that looped tacking operations meet quality standards and production deadlines.

- May be involved in troubleshooting and resolving machine issues.

- Contributes to overall garment production efficiency and quality.

8. How do you stay updated with the latest advancements in looped tacking technology?

- Attend industry conferences and trade shows.

- Read trade publications and online resources.

- Network with other Loop Tackers and industry professionals.

- Participate in training programs offered by machine manufacturers.

- Stay informed about new products and technologies through research and development.

9. What motivates you to excel as a Loop Tacker?

- Passion for precision and attention to detail.

- Desire to contribute to the quality of garments.

- Appreciation for the role of looped tacking in garment construction.

- Interest in troubleshooting and problem-solving.

- Commitment to teamwork and collaboration.

10. How would you handle a situation where you encounter a complex or challenging looped tacking task?

- Analyze the task and identify potential challenges.

- Consult with experienced colleagues or supervisors for guidance.

- Research and explore different approaches.

- Experiment with different stitch types and settings to find the optimal solution.

- Remain patient and persistent in finding a satisfactory solution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Loop Tacker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Loop Tacker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Loop Tacker is responsible for the smooth and efficient operation of the manufacturing process by ensuring the proper tacking of loops in the production line.

1. Loop Tacking and Production Monitoring

The primary responsibility is to tack loops effectively, maintain consistent production speeds, and monitor the overall production process to identify and address any issues promptly.

- Tack loops accurately and efficiently using specialized equipment.

- Monitor production lines, identify errors and bottlenecks, and take corrective actions.

- Maintain a high level of accuracy and attention to detail to minimize defects.

2. Machine Maintenance and Calibration

Ensuring the proper functioning of the loop-tacking machinery is essential. Loop Tackers are responsible for routine maintenance, calibration, and troubleshooting.

- Perform regular maintenance checks, clean and lubricate equipment.

- Calibrate machinery according to manufacturer’s specifications.

- Troubleshoot and resolve technical issues to maintain optimal performance.

3. Quality Control and Inspection

Loop Tackers play a crucial role in maintaining product quality. They conduct regular inspections to ensure loops are tacked correctly and meet the specified standards.

- Inspect tacked loops for defects, ensuring they meet quality specifications.

- Monitor finished products for any irregularities or inconsistencies in tacking.

- Report quality issues and suggest corrective actions to improve production processes.

4. Health and Safety Compliance

Adhering to safety regulations and maintaining a clean and organized work environment are paramount. Loop Tackers must follow health and safety protocols.

- Comply with established health and safety regulations and procedures.

- Maintain a clean and organized work area to prevent accidents.

- Report any safety concerns or potential hazards to supervisors promptly.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Loop Tacker position:

1. Research the Company and Position

Before the interview, take the time to research the company, its products or services, and the specific Loop Tacker role. This knowledge will demonstrate your interest and understanding of the position.

- Visit the company website to gather information about their operations, values, and industry presence.

- Read job descriptions carefully to understand the specific requirements and responsibilities.

- Prepare questions to ask the interviewer, showing your engagement and interest.

2. Practice Common Interview Questions

Anticipate and practice answering common interview questions. This will help you articulate your skills, experience, and qualifications confidently.

- Common questions: “Tell me about yourself,” “Why are you interested in this position?” and “Why should we hire you?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples.

- Practice speaking clearly and concisely, highlighting your relevant skills and accomplishments.

3. Highlight Your Experience and Skills

Emphasize your relevant experience and skills during the interview. Quantify your accomplishments whenever possible to showcase the value you can bring to the company.

- Discuss your experience in loop-tacking operations, equipment maintenance, and quality control.

- Provide specific examples demonstrating your ability to work independently and as part of a team.

- Mention any certifications or training programs that strengthen your qualifications.

4. Be Prepared to Discuss Safety

Health and safety are crucial in manufacturing environments. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain your knowledge of industry-specific safety regulations and best practices.

- Describe your experience in adhering to safety procedures and reporting hazards.

- Emphasize your ability to work safely and efficiently in a fast-paced production setting.

5. Ask Questions and Follow Up

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest. It also gives you an opportunity to clarify any details or express any concerns.

- Prepare questions about the company’s production process, quality standards, and safety initiatives.

- Follow up with the interviewer after the interview to thank them for their time and reiterate your interest in the position.

- Be professional and courteous throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Loop Tacker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Loop Tacker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.