Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Looping Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Looping Machine Operator so you can tailor your answers to impress potential employers.

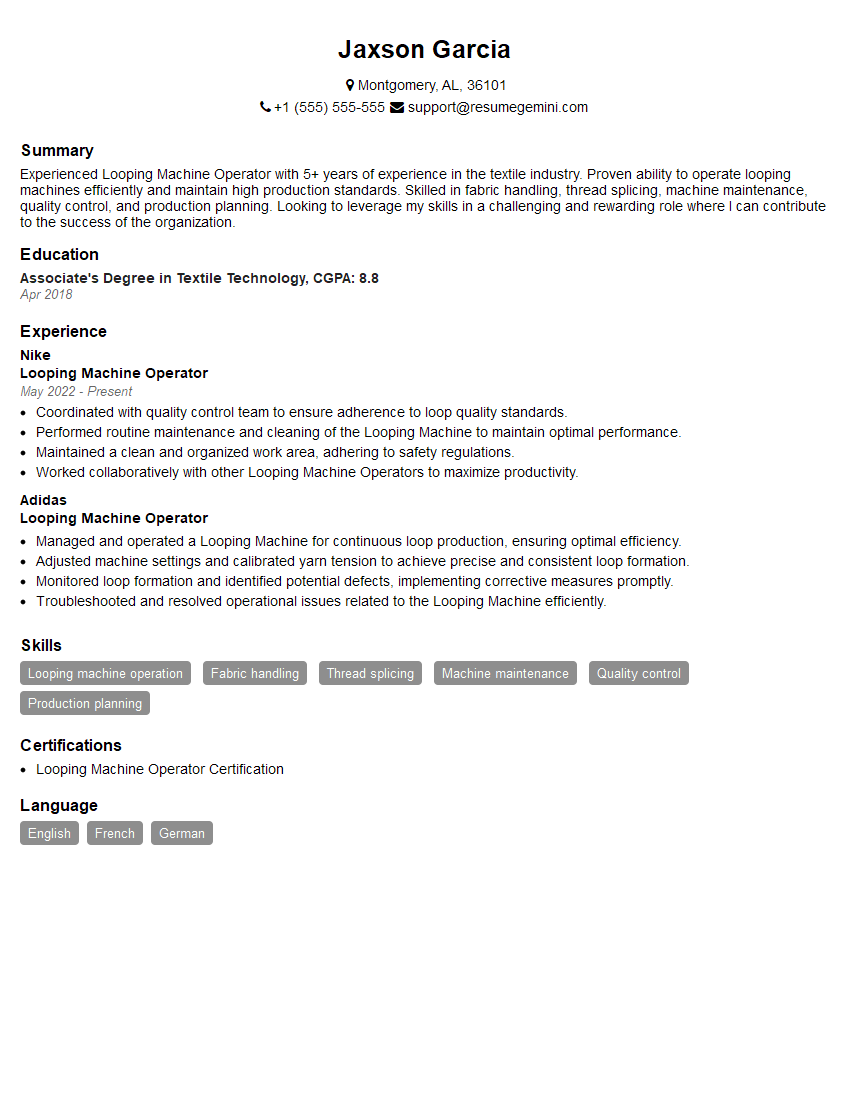

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Looping Machine Operator

1. Explain the process of setting up a looping machine?

- Inspect the machine and make sure it is clean and in good working order.

- Load the fabric onto the machine’s feed table.

- Thread the fabric through the machine’s guides and tensioners.

- Set the machine’s speed and tension settings.

- Start the machine and check the loop formation.

2. What are the different types of stitches that can be used on a looping machine?

Woven Stitch

- Strong and durable stitch.

- Used for a wide range of fabrics and applications.

Knit Stitch

- Stretchy and elastic stitch.

- Used for fabrics that need to stretch, such as sportswear and swimwear.

3. How do you troubleshoot a looping machine that is not producing loops correctly?

- Check the thread tension.

- Check the needle for damage or debris.

- Check the feed dogs for proper operation.

- Check the looper for proper timing.

- Check the machine’s manual for additional troubleshooting tips.

4. What are the safety precautions that should be taken when operating a looping machine?

- Wear appropriate safety gear, such as safety glasses and gloves.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

- Follow the manufacturer’s instructions for safe operation.

5. How do you maintain a looping machine to ensure its optimal performance?

- Clean the machine regularly to remove lint and debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for worn or damaged parts and replace them as needed.

- Have the machine serviced by a qualified technician on a regular basis.

6. What are the different types of fabrics that can be used on a looping machine?

- Woven fabrics

- Knit fabrics

- Non-woven fabrics

- Stretch fabrics

- Upholstery fabrics

7. What are the different applications of looped fabrics?

- Clothing

- Home furnishings

- Industrial products

- Medical products

- Automotive products

8. What are the advantages of using a looping machine over other sewing machines?

- Produces high-quality, uniform loops.

- Can sew a wide range of fabrics.

- Can be used for a variety of applications.

- Relatively easy to operate.

9. What are the challenges of operating a looping machine?

- Requires a high level of skill to operate.

- Can be difficult to troubleshoot if problems arise.

- Can be expensive to purchase and maintain.

10. What is your experience with looping machines?

I have worked as a looping machine operator for the past 5 years. In this role, I have been responsible for setting up, operating, and maintaining looping machines. I have experience with a variety of looping machines, including single-needle, double-needle, and multi-needle machines. I am also familiar with a variety of fabrics and applications for looped fabrics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Looping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Looping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Looping Machine Operators are responsible for operating and maintaining looping machines used in the production of garments. Their key responsibilities include:

1. Machine Operation

Operating looping machines to stitch together garment panels, such as sleeves, collars, and waistbands.

- Setting up and adjusting machines according to predetermined specifications.

- Loading and unloading fabrics and threads onto machines.

2. Quality Control

Inspecting stitched garments for defects, such as skipped stitches, loose threads, or uneven seams.

- Identifying and correcting errors during the looping process.

- Ensuring that garments meet quality standards.

3. Maintenance and Repair

Performing basic maintenance on looping machines, such as cleaning, lubricating, and adjusting parts.

- Identifying and troubleshooting machine malfunctions.

- Making minor repairs or calling for professional assistance when necessary.

4. Production and Efficiency

Meeting production targets by maintaining a consistent work pace.

- Monitoring machine performance and making adjustments to optimize output.

- Collaborating with other operators to ensure smooth production flow.

Interview Tips

To ace an interview for a Looping Machine Operator position, candidates should focus on demonstrating their technical abilities, attention to detail, and problem-solving skills.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This shows that you are interested in the role and have taken the time to learn about the company.

2. Highlight Relevant Experience and Skills

Quantify your accomplishments and provide specific examples of how you have successfully operated looping machines, maintained quality standards, and solved production issues.

3. Practice Common Interview Questions

Prepare for questions related to your experience with looping machines, quality control procedures, and troubleshooting techniques. Practice answering these questions clearly and concisely.

4. Be Prepared to Discuss Safety and Maintenance

Emphasize your understanding of safety protocols for operating looping machines and your ability to perform basic maintenance tasks, ensuring that you can maintain a safe and productive work environment.

5. Ask Thoughtful Questions

During the interview, ask questions that show your interest in the role and the company. This demonstrates your enthusiasm and eagerness to learn more about the position.

Next Step:

Now that you’re armed with the knowledge of Looping Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Looping Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini