Are you gearing up for an interview for a Lubricating Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lubricating Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

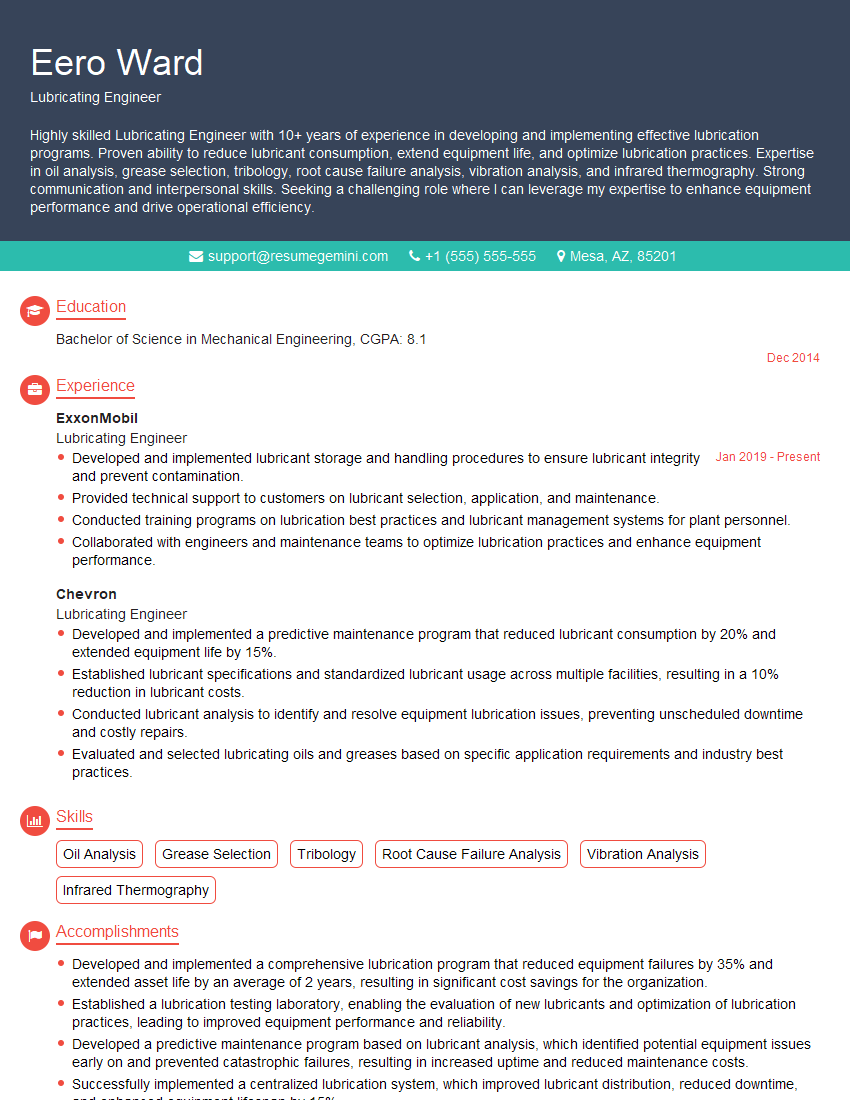

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubricating Engineer

1. Describe the key properties of lubricating oils and greases?

- Lubricating oils possess viscosity, which enables them to resist flow, ensuring proper film formation between mating surfaces.

- Greases, on the other hand, combine base oils with thickeners, forming semi-solid lubricants that offer exceptional adhesion and sealing capabilities.

- Both oils and greases play crucial roles in reducing friction, wear, and heat generation within machinery.

2. Explain the different types of lubrication regimes.

- Boundary lubrication: At low sliding speeds and high loads, direct contact occurs between surfaces, and lubricants act as a boundary layer to prevent scuffing or seizure.

- Mixed lubrication: As speeds and loads increase, a combination of boundary and hydrodynamic lubrication occurs, reducing direct surface contact.

- Hydrodynamic lubrication: At higher speeds and lighter loads, a complete lubricating film separates surfaces, preventing metal-to-metal contact.

- Elastohydrodynamic lubrication: In heavily loaded, non-conforming contacts, such as those found in gears, the lubricant film undergoes elastic deformation, further enhancing load-carrying capacity.

3. How do you determine the appropriate lubricant for a specific application?

- Consider the operating environment, including temperature, load, and speed.

- Analyze the characteristics of the equipment, such as material composition, surface finish, and design features.

- Review industry standards and manufacturer recommendations for suitable lubricants.

- Conduct lubricant testing to assess performance under specific operating conditions.

4. Describe the process of establishing an effective lubrication program.

- Develop a lubrication schedule based on equipment needs and operating conditions.

- Implement a system for lubricant storage, handling, and application.

- Monitor lubricant condition through regular oil analysis and inspections.

- Train personnel on proper lubrication practices and safety protocols.

5. Explain the role of additives in lubricating oils and greases.

- Anti-wear additives: Protect surfaces from wear by forming a protective layer on metal surfaces.

- Anti-oxidants: Inhibit lubricant degradation due to oxidation and thermal stress.

- Detergents: Remove contaminants and prevent deposit formation.

- Corrosion inhibitors: Protect metal surfaces from corrosion caused by moisture or acids.

6. Discuss the importance of lubrication in preventing bearing failures.

- Lubrication ensures sufficient film formation to separate bearing surfaces, preventing metal-to-metal contact and wear.

- It reduces friction, minimizing heat generation and energy loss.

- Lubricants also help protect bearings from contamination, corrosion, and oxidation.

- Proper lubrication extends bearing life, reduces maintenance costs, and improves overall equipment reliability.

7. How do you approach lubrication system troubleshooting and optimization?

- Identify potential issues through regular inspections, oil analysis, and vibration monitoring.

- Analyze lubricant condition and system components to determine the root cause of problems.

- Consider factors such as lubricant selection, application methods, and environmental conditions.

- Implement corrective actions, such as lubricant changes, system modifications, or improved maintenance practices.

8. Describe the latest advancements in lubrication technology.

- Synthetic lubricants: Offer superior performance under extreme temperatures and operating conditions.

- Specialty lubricants: Designed for specific applications, such as food-grade or high-vacuum environments.

- Nanotechnology: Incorporates nanoparticles to enhance lubricant properties.

- Condition monitoring sensors: Integrated into lubrication systems to monitor lubricant health and system performance.

9. How do you stay up-to-date with industry best practices and technological developments in the field of lubrication engineering?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Engage with professional organizations and network with peers.

- Participate in training and certification programs.

10. Share a challenging lubrication problem you encountered and how you resolved it.

- Describe the issue in detail, including equipment type, operating conditions, and symptoms.

- Explain your approach to troubleshooting, including data analysis, lubricant testing, and system modifications.

- Highlight the specific actions you took to resolve the problem and the results achieved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubricating Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubricating Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubricating Engineers hold a critical role in ensuring the smooth and efficient operation of machinery and equipment across various industries.

1. Lubrication Management and Analysis

Develop and implement lubrication strategies to optimize equipment performance and extend its lifespan.

- Identify and select appropriate lubricants based on equipment specifications and operating conditions.

- Establish lubrication schedules, intervals, and quantities to ensure optimal lubrication.

2. Lubricant Testing and Condition Monitoring

Monitor and analyze lubricant properties to ensure they meet industry standards and equipment requirements.

- Conduct oil analysis, including viscosity, acidity, and wear debris, to identify potential issues.

- Use condition monitoring techniques, such as vibration analysis and temperature monitoring, to detect equipment problems at an early stage.

3. Equipment Inspection and Troubleshooting

Inspect equipment to identify lubrication-related issues and recommend corrective actions.

- Assess equipment condition, including seals, bearings, and gears, to identify potential lubrication problems.

- Troubleshoot lubrication-related issues, such as excessive wear, overheating, and increased vibration.

4. Training and Support

Provide training and support to maintenance personnel on lubrication best practices.

- Develop and deliver training programs on lubrication principles, techniques, and safety procedures.

- Provide technical support and guidance to maintenance teams on lubrication-related matters.

Interview Tips

To ace your interview for a Lubricating Engineer role, preparation is key. Here are some essential tips to help you stand out from the crowd:

1. Research the Company and Role

Thoroughly research the company’s industry, products, and current projects. This will provide context for your answers and demonstrate your interest in the specific role.

2. Highlight Relevant Experience

Emphasize your experience in lubrication management, lubricant testing, equipment inspection, and troubleshooting. Provide specific examples that showcase your expertise.

3. Demonstrate Problem-Solving Abilities

Interviewers will be eager to know how you approach and solve lubrication-related problems. Share examples of how you identified issues, analyzed data, and implemented effective solutions.

4. Showcase Communication Skills

Lubricating Engineers often work closely with maintenance teams and other stakeholders. Highlight your ability to communicate technical information clearly and effectively.

5. Prepare Industry-Specific Questions

Ask informed questions about the company’s lubrication practices, industry trends, or specific equipment used in their operations. This shows your enthusiasm for the field and your desire to learn more.

Next Step:

Now that you’re armed with the knowledge of Lubricating Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lubricating Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini