Are you gearing up for a career in Lubrication Equipment Servicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lubrication Equipment Servicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

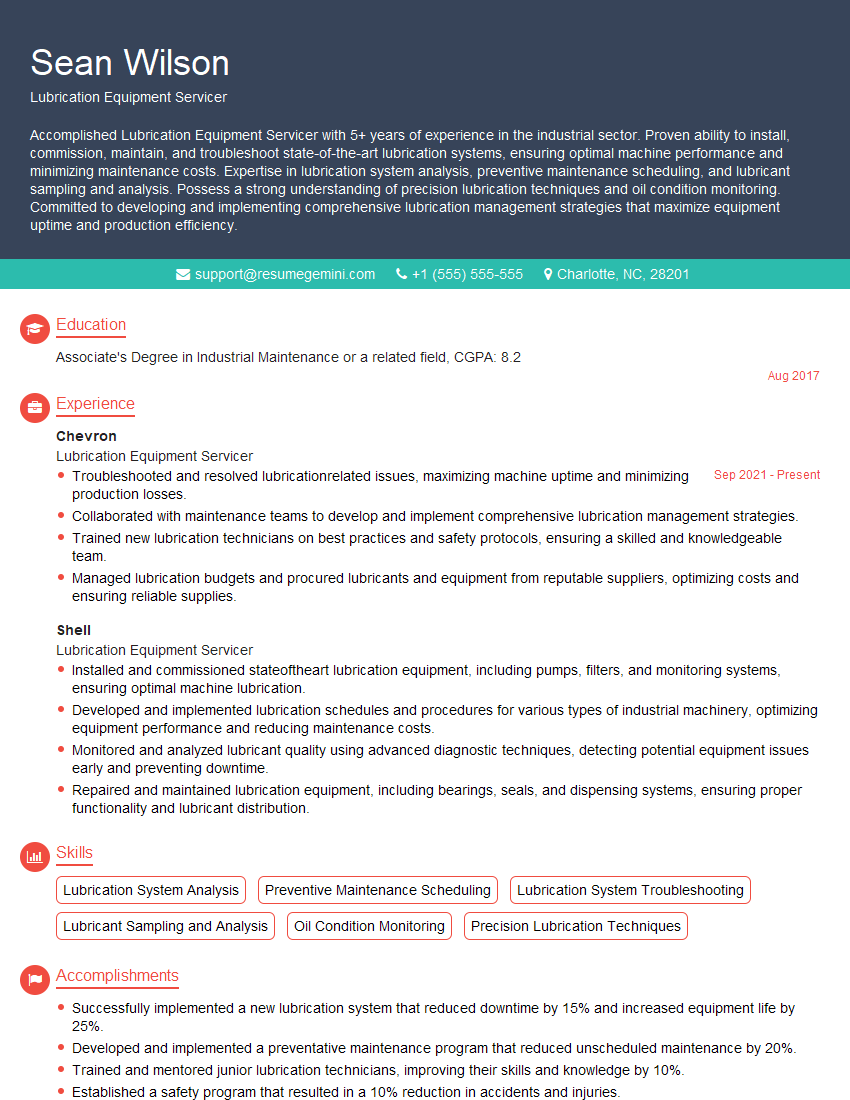

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubrication Equipment Servicer

1. How do you ensure that lubrication equipment is operating efficiently and effectively?

To ensure efficient and effective lubrication equipment operation, I follow a structured approach:

- Regular Inspections: I conduct thorough inspections to identify any potential issues, such as leaks, blockages, or worn components.

- Precision Calibration: I calibrate equipment regularly to maintain accuracy in dispensing and monitoring lubrication levels.

- Optimizing Lubrication Schedules: I analyze equipment usage and operating conditions to establish optimal lubrication intervals, ensuring proper lubrication without over-lubrication.

2. Describe the steps involved in troubleshooting and repairing lubrication systems.

Diagnosing the Problem:

- Isolate the affected component or system.

- Review system logs and historical data to identify trends or patterns.

- Physically inspect components for signs of wear, leaks, or damage.

Repairing the System:

- Identify and replace faulty components.

- Clean and lubricate the system to prevent further issues.

- Re-calibrate and test the system to ensure proper operation.

3. How do you stay up-to-date with the latest advancements in lubrication equipment technology?

To keep pace with advancements in lubrication technology, I:

- Attend Industry Events: I participate in conferences and exhibitions to interact with experts and learn about new technologies and best practices.

- Study Technical Publications: I regularly review trade journals, manufacturer literature, and online resources to stay informed about industry developments.

- Seek Training and Certification: I pursue ongoing training and certifications to enhance my knowledge and skills in lubrication equipment maintenance and repair.

4. What steps do you take to ensure the safety of yourself and others when working with lubrication equipment?

Safety is my top priority when working with lubrication equipment. I adhere to the following practices:

- Wear Protective Gear: I use appropriate personal protective equipment (PPE) such as gloves, eye protection, and coveralls.

- Follow Lockout/Tagout Procedures: I isolate and de-energize equipment before performing maintenance or repairs.

- Handle Hazardous Materials Safely: I follow established protocols for handling and disposing of lubricants and cleaning agents.

5. How do you manage and prioritize your workload when dealing with multiple lubrication equipment service requests?

I effectively manage my workload by:

- Prioritizing Urgency: I assess the severity of requests and prioritize those that require immediate attention.

- Scheduling Efficiently: I plan my work schedule to minimize downtime and ensure timely completion of tasks.

- Delegating Responsibilities: When necessary, I delegate non-critical tasks to colleagues to distribute the workload effectively.

6. How do you communicate effectively with operators and managers regarding lubrication equipment maintenance and repairs?

Clear communication is crucial. I:

- Use Clear Language: I simplify technical information to ensure understanding by non-technical audiences.

- Provide Regular Updates: I keep operators and managers informed of equipment status, maintenance schedules, and potential issues.

- Document Thoroughly: I create detailed reports and maintenance logs to provide a record of work performed and recommendations.

7. Describe your experience with different types of lubrication equipment.

I have extensive experience with various lubrication equipment, including:

- Automated Grease Systems: I have installed, maintained, and repaired automated grease systems for industrial machinery.

- Oil Circulating Systems: I have experience with the installation and maintenance of oil circulating systems for turbines and compressors.

- Minimum Quantity Lubrication (MQL) Systems: I am familiar with the operation and troubleshooting of MQL systems used in machining applications.

8. What are some common lubrication equipment maintenance mistakes that you have encountered, and how did you resolve them?

Some common lubrication equipment maintenance mistakes I have encountered include:

- Over-Lubrication: This can lead to excessive drag and contamination. I resolve it by adjusting lubrication schedules and optimizing lubricant viscosity.

- Incorrect Lubricant Selection: Using the wrong lubricant can cause premature equipment failure. I address this by consulting manufacturer recommendations and conducting lubricant analysis.

- Improper Storage: This can affect lubricant quality. I ensure proper storage conditions and implement inventory controls to prevent contamination.

9. How do you stay motivated and maintain a positive attitude when faced with challenges in your work?

Staying motivated and positive is essential. Here’s how I do it:

- Set Realistic Goals: Breaking down large tasks into smaller, achievable goals helps me stay focused and motivated.

- Focus on Problem-Solving: I view challenges as opportunities for learning and growth. I approach them with a positive mindset, seeking solutions rather than dwelling on obstacles.

- Seek Support: I build relationships with colleagues and supervisors. Their support and encouragement provide a boost during challenging times.

10. What are your career goals and how do you see this role contributing to your professional development?

My career goal is to become a highly skilled and knowledgeable Lubrication Equipment Specialist. This role will contribute to my professional development by:

- Expanding My Knowledge: I will gain hands-on experience with a wide range of lubrication equipment and maintenance techniques.

- Developing Troubleshooting Skills: I will hone my diagnostic and problem-solving abilities through practical experience.

- Networking and Mentorship: I look forward to collaborating with colleagues and learning from experienced professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubrication Equipment Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubrication Equipment Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubrication Equipment Servicers are responsible for the maintenance and repair of equipment used to lubricate machinery and other equipment.

1. Installation and Maintenance

Installing and maintaining lubrication equipment in accordance with manufacturers’ specifications and industry standards.

- Inspect and test equipment to ensure it is functioning properly.

- Troubleshoot and repair equipment malfunctions.

2. Lubrication and Monitoring

Lubricating machinery and monitoring its performance to ensure proper lubrication.

- Monitor fluid levels and lubricate equipment as needed.

- Test lubricated equipment to ensure it is functioning properly.

3. Calibration and Inspection

Calibrating and inspecting lubrication equipment to ensure accuracy and reliability.

- Calibrate equipment according to manufacturers’ specifications.

- Inspect equipment for wear and tear and replace parts as needed.

4. Safety and Environment

Ensuring that all lubrication-related activities are performed in a safe and environmentally responsible manner.

- Comply with all safety and environmental regulations.

- Dispose of hazardous materials properly.

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Lubrication Equipment Servicer position:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read industry news and articles.

- Practice answering common interview questions.

2. Highlight Relevant Experience and Skills

When answering interview questions, focus on highlighting your relevant experience and skills. Use specific examples to demonstrate how you have successfully performed the key job responsibilities of a Lubrication Equipment Servicer.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your knowledge of lubrication equipment.

- Emphasize your safety and environmental awareness.

3. Be Enthusiastic and Professional

First impressions matter, so be sure to arrive on time for your interview and dress professionally. Throughout the interview, maintain a positive and enthusiastic attitude and be respectful of the interviewer’s time.

- Make eye contact and speak clearly.

- Ask thoughtful questions.

- Thank the interviewer for their time.

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a great opportunity to reiterate your interest in the position and highlight any additional qualifications or experience that you may have forgotten to mention during the interview.

- Restate your key strengths.

- Reiterate your interest in the position.

- Thank the interviewer again for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lubrication Equipment Servicer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!