Are you gearing up for an interview for a Lumber Grader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lumber Grader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

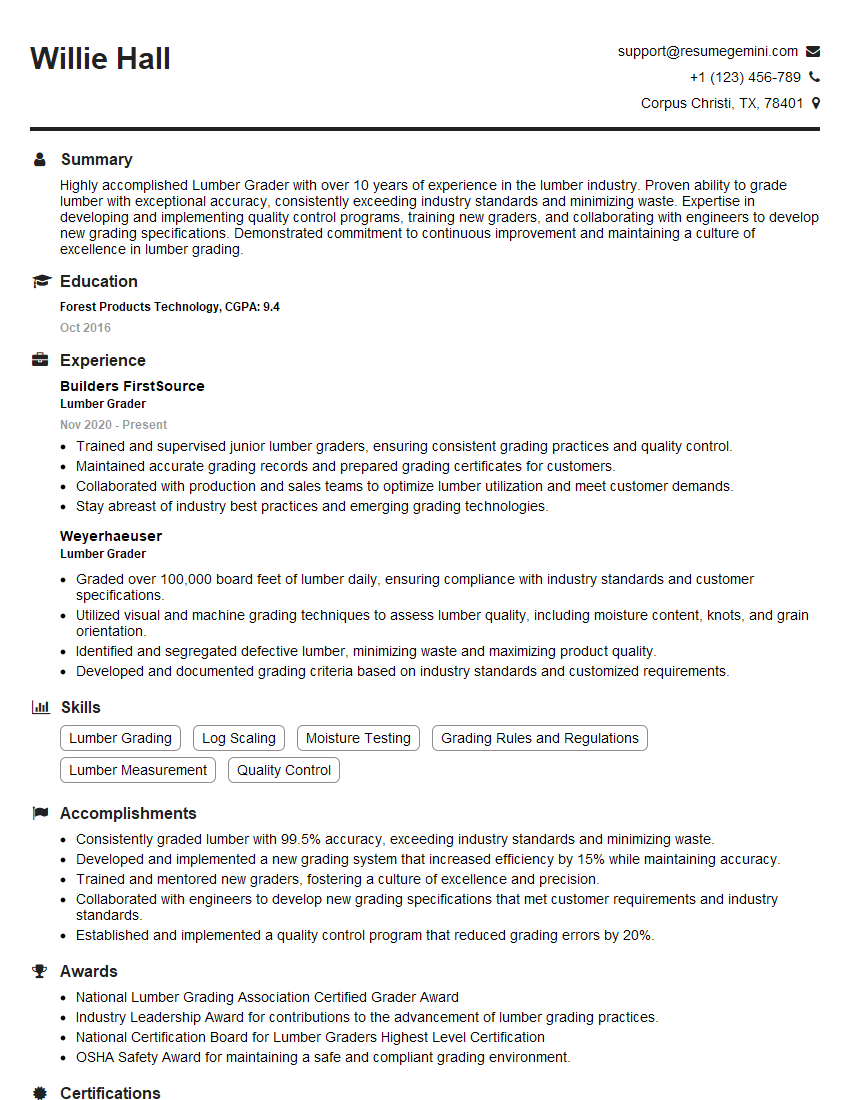

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Grader

1. How do you determine the grade of a piece of lumber?

I determine the grade of a piece of lumber by considering several factors, including:

- Knots: I assess the size, number, and location of knots, as they can affect the strength and appearance of the lumber.

- Grain pattern: I examine the grain pattern to determine if there are any irregularities or defects that could impact the lumber’s structural integrity.

- Warp: I check for any warping or twisting in the lumber, as these can affect its usability and stability.

- Checks: I inspect for checks or splits in the lumber, which can reduce its strength and durability.

2. What are the different grades of lumber, and what are their typical uses?

Construction Grades

- Select Structural: Used for load-bearing applications such as beams and rafters.

- No. 1: Suitable for framing, joists, and other general construction purposes.

- No. 2: Commonly used for studs, sheathing, and crates.

Appearance Grades

- Clear: Virtually defect-free, used for fine woodworking and furniture.

- Select: Few minor defects, used for cabinetry, molding, and interior trim.

- Common: More defects allowed, used for exterior siding, fences, and other applications where appearance is less critical.

3. How do you measure the moisture content of lumber?

I measure the moisture content of lumber using a moisture meter. This device is inserted into the lumber, and it provides a reading of the percentage of moisture present. The moisture content is an important factor to consider, as it can affect the stability and durability of the lumber.

4. What are the different types of wood defects, and how do they affect the quality of lumber?

- Knots: These are areas where branches have grown out of the tree. Knots can weaken the lumber and reduce its strength.

- Grain distortion: This is a condition where the grain of the wood is not straight. Grain distortion can make the lumber more difficult to work with and can also reduce its strength.

- Warp: This is a condition where the lumber is not flat. Warp can make the lumber difficult to use and can also reduce its strength.

- Checks: These are cracks in the lumber. Checks can reduce the strength of the lumber and make it more susceptible to decay.

5. What are the most important factors to consider when selecting lumber for a specific project?

- The grade of the lumber: The grade of the lumber will determine its strength and appearance.

- The moisture content of the lumber: The moisture content of the lumber will affect its stability and durability.

- The type of wood: The type of wood will determine its strength, durability, and appearance.

- The size of the lumber: The size of the lumber will determine its suitability for the project.

6. How do you store lumber to prevent warping and other damage?

I store lumber in a dry, well-ventilated area. I stack the lumber on stickers to allow air to circulate around it. I also cover the lumber with a tarp or plastic to protect it from the elements.

7. What are the safety precautions that must be taken when working with lumber?

- Wear appropriate personal protective equipment, such as gloves, eye protection, and a dust mask.

- Use sharp tools and equipment.

- Be aware of your surroundings and avoid tripping hazards.

- Do not lift heavy objects alone.

8. What are the most common problems that you encounter when grading lumber?

- Knots: Knots are the most common problem that I encounter when grading lumber. Knots can weaken the lumber and reduce its strength.

- Grain distortion: Grain distortion is another common problem that I encounter when grading lumber. Grain distortion can make the lumber more difficult to work with and can also reduce its strength.

- Warp: Warp is a condition where the lumber is not flat. Warp can make the lumber difficult to use and can also reduce its strength.

- Checks: Checks are cracks in the lumber. Checks can reduce the strength of the lumber and make it more susceptible to decay.

9. How do you stay up-to-date on the latest industry standards and best practices for lumber grading?

I stay up-to-date on the latest industry standards and best practices for lumber grading by reading industry publications and attending industry conferences and workshops.

10. What qualities make a successful Lumber Grader?

- A strong understanding of the different grades of lumber and their uses.

- The ability to identify and measure lumber defects.

- The ability to work independently and as part of a team.

- Strong communication and interpersonal skills.

- A commitment to accuracy and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lumber Graders are responsible for ensuring that lumber meets the necessary standards for quality and safety. Their primary duties involve:

1. Lumber Inspection

Inspecting and grading lumber based on various criteria, such as species, size, moisture content, and appearance

- Assessing the quality of lumber by examining its physical characteristics, including knots, splits, and grain patterns

- Measuring and classifying lumber according to established grading rules and standards

2. Quality Control

Maintaining quality standards by monitoring the production process and identifying any deviations

- Implementing quality control procedures to ensure that lumber meets specifications

- Conducting regular inspections to detect defects or inconsistencies in lumber

3. Customer Service

Interacting with customers to provide information and resolve any issues regarding lumber quality

- Answering customer inquiries about lumber grades, specifications, and availability

- Resolving customer complaints and providing solutions to ensure satisfaction

4. Record Keeping

Maintaining accurate records of lumber inspections, grades, and shipments

- Documenting lumber grades, quantities, and customer information

- Preparing reports on lumber quality and production

Interview Tips

To ace a Lumber Grader interview, it’s essential to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Industry

Learn about the company’s history, products, and market position. Understanding the lumber industry’s trends and challenges will demonstrate your interest and knowledge.

- Visit the company’s website and read industry publications

- Identify the company’s competitors and market share

2. Highlight Relevant Skills and Experience

Emphasize your experience in lumber grading, quality control, and customer service. Quantify your accomplishments and provide specific examples of your work.

- Describe your role in implementing quality control procedures

- Share an example of how you resolved a customer complaint

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and knowledge of the lumber industry. Practice answering these questions clearly and concisely.

- Why are you interested in this role?

- What is your understanding of lumber grading standards?

- How would you handle a customer complaint about lumber quality?

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare questions about the company’s goals, industry trends, or the role’s specific responsibilities.

- What are the company’s plans for future growth?

- What are the key challenges facing the lumber industry today?

- How does the company ensure the sustainability of its lumber sourcing?

Next Step:

Now that you’re armed with the knowledge of Lumber Grader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lumber Grader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini