Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lumber Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

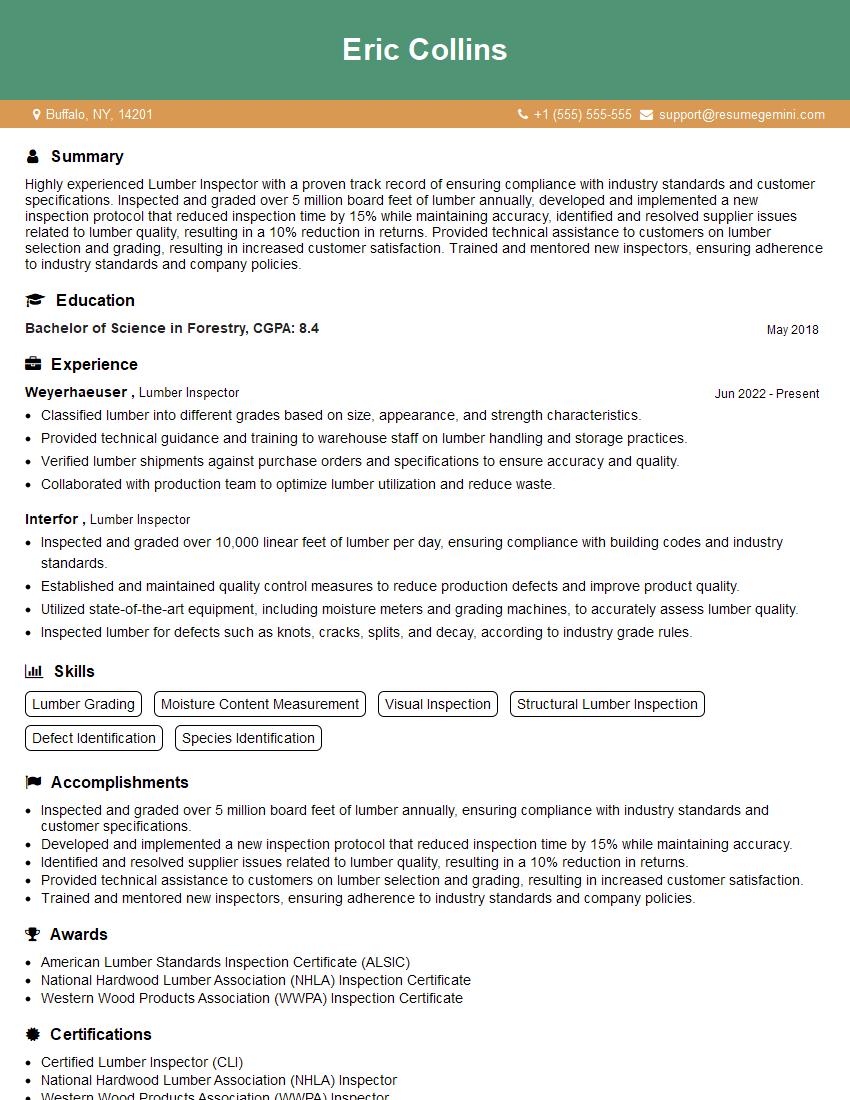

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Inspector

1. What are the key qualities of a successful Lumber Inspector?

- Strong knowledge of wood species and their characteristics

- Ability to identify and grade lumber based on established standards

- Excellent visual acuity and attention to detail

- Understanding of lumber manufacturing processes

- Ability to work independently and as part of a team

2. Describe the steps involved in grading lumber?

The steps involved in grading lumber include:

Visual inspection:

- Examining the lumber for knots, splits, wane, and other defects

- Measuring the lumber for size and shape

Mechanical testing:

- Performing tests to determine the lumber’s strength and durability

- Assigning a grade based on the results of the inspection and testing

3. What are the different lumber grades and how are they determined?

Lumber grades are determined based on the quality and appearance of the wood. The most common lumber grades include:

- Select: This is the highest grade of lumber and is free of defects.

- No. 1 Common: This grade has some minor defects, but is still suitable for most applications.

- No. 2 Common: This grade has more defects than No. 1 Common, but is still suitable for framing and other construction purposes.

- No. 3 Common: This grade has the most defects and is typically used for rough construction or for making pallets.

4. What are the different factors that can affect the grade of lumber?

The factors that can affect the grade of lumber include:

- The species of wood

- The number and size of knots

- The presence of splits, wane, or other defects

- The moisture content of the wood

- The manufacturing process

5. What are the different types of defects that can be found in lumber?

The different types of defects that can be found in lumber include:

- Knots: Knots are caused by the growth of branches on the tree. They can vary in size and shape, and can affect the strength of the lumber.

- Splits: Splits are cracks in the wood that can occur during the drying process or due to stress.

- Wane: Wane is the bark or edge of the tree that is left on the lumber during the milling process.

- Warp: Warp is a distortion in the shape of the lumber that can occur during the drying process or due to stress.

- Decay: Decay is a fungal infection that can cause the wood to rot.

6. What are the different methods used to preserve lumber?

The different methods used to preserve lumber include:

- Pressure treatment: This process involves treating the lumber with a preservative under pressure.

- Dip treatment: This process involves dipping the lumber in a preservative.

- Brush treatment: This process involves applying a preservative to the lumber with a brush.

- Spray treatment: This process involves spraying the lumber with a preservative.

7. What are the safety precautions that should be taken when working with lumber?

The safety precautions that should be taken when working with lumber include:

- Wearing proper safety gear, including gloves, safety glasses, and a hard hat.

- Using sharp tools and equipment.

- Being aware of the surroundings and potential hazards.

- Lifting heavy lumber with proper techniques.

- Stacking lumber properly to prevent it from falling.

8. What are the different types of lumber products?

The different types of lumber products include:

- Dimensional lumber: This is lumber that is used for framing and other construction purposes.

- Plywood: This is a type of lumber that is made from thin layers of wood that are glued together.

- Oriented strand board (OSB): This is a type of lumber that is made from strands of wood that are glued together.

- Medium-density fiberboard (MDF): This is a type of lumber that is made from wood fibers that are glued together.

- Hardboard: This is a type of lumber that is made from wood fibers that are compressed together.

9. What are the different uses for lumber?

Lumber is used in a variety of applications, including:

- Construction: Lumber is used for framing, sheathing, roofing, and other construction purposes.

- Furniture: Lumber is used for making furniture, cabinets, and other furniture items.

- Pallets: Lumber is used for making pallets for shipping.

- Paper: Lumber is used for making paper.

- Fuel: Lumber is used for heating and cooking.

10. What is the outlook for the lumber industry?

The outlook for the lumber industry is positive. The demand for lumber is expected to grow in the coming years due to increasing population and economic growth. However, the industry is also facing challenges, such as climate change and the rising cost of raw materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lumber Inspector is a quality assurance professional who plays a crucial role in the lumber industry by ensuring that the lumber meets the required standards and specifications. The key job responsibilities of a Lumber Inspector include:

1. Lumber Inspection

Inspecting lumber for defects, such as knots, splits, and stains, to assess its quality and grade.

- Using specialized tools and equipment to measure lumber dimensions, such as thickness, width, and length.

- Verifying the moisture content of lumber to ensure it meets industry standards.

2. Grading Lumber

Grading lumber based on its quality and performance characteristics, such as strength, durability, and appearance.

- Applying grading rules and standards established by industry organizations.

- Determining the appropriate grade for each piece of lumber based on its inspection results.

3. Quality Control

Maintaining quality control throughout the lumber production process, from raw materials to finished products.

- Inspecting lumber at various stages of production to identify and resolve quality issues.

- Collaborating with production teams to implement corrective actions and improve lumber quality.

4. Documentation

Preparing and maintaining accurate records of lumber inspections, grading results, and quality control measures.

- Documenting the reasons for downgrading or rejecting lumber.

- Providing feedback to production teams and management on lumber quality trends.

Interview Tips

Preparing thoroughly for a Lumber Inspector interview can significantly increase your chances of success. Here are some helpful tips:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific requirements of the Lumber Inspector position. This will help you understand the company’s values, industry knowledge, and what they are looking for in a candidate.

- Visit the company’s website to gather information about their products, services, and industry standing.

- Review the job description carefully to identify the essential qualifications and responsibilities.

2. Highlight Your Skills and Experience

Use the job description as a guide to tailor your resume and interview responses. Emphasize your relevant skills and experience, such as:

- Lumber inspection techniques and grading standards.

- Quality control procedures and documentation.

- Understanding of lumber production processes.

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. Here are some examples:

- Tell me about your experience in lumber inspection.

- How do you determine the grade of a piece of lumber?

- What are the most common defects you encounter in lumber?

- How do you handle situations where you have to reject lumber?

- What are your strengths and weaknesses as a Lumber Inspector?

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare some questions, such as:

- What are the company’s quality control standards for lumber?

- What opportunities are there for professional development and advancement?

- How does the company stay updated on the latest lumber industry trends and technologies?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lumber Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.