Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lumber Kiln Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

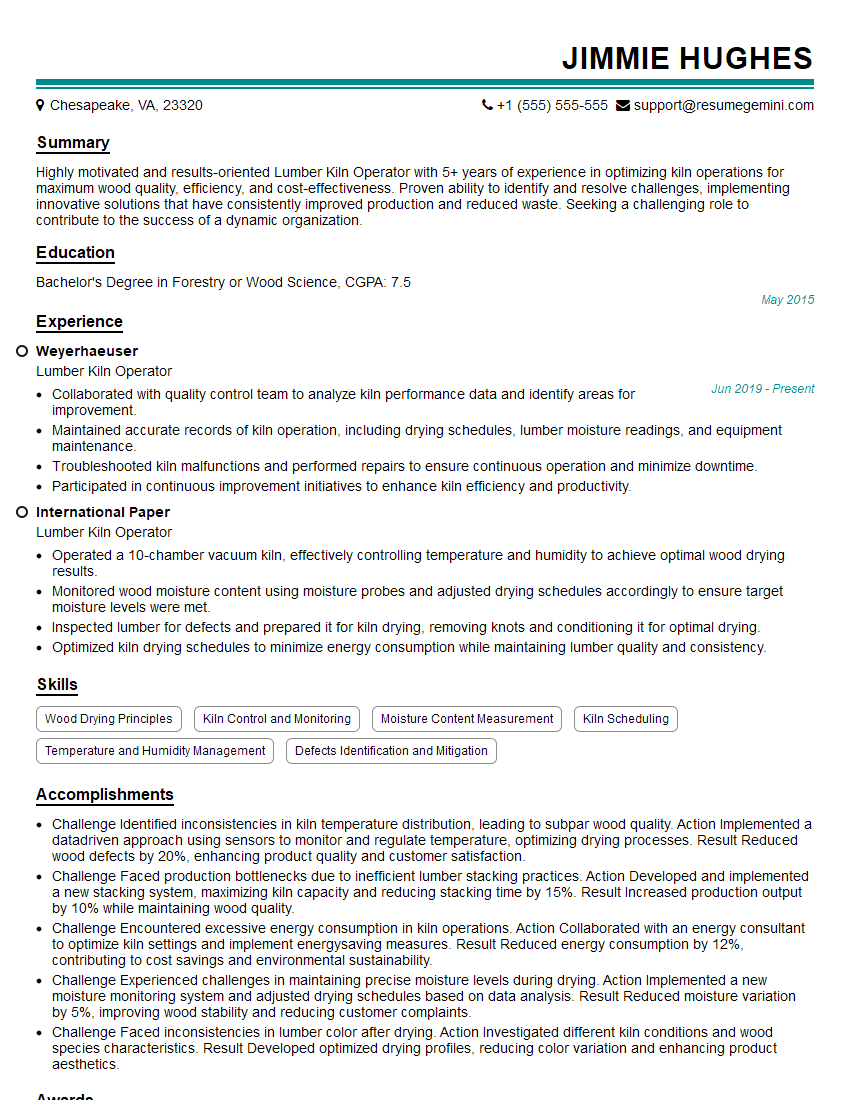

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Kiln Operator

1. What are the key factors to consider when operating a lumber kiln?

There are several key factors that I consider when operating a lumber kiln:

- Moisture content of the lumber: The moisture content of the lumber is a crucial factor that determines the drying time and quality of the final product. I carefully monitor the moisture content throughout the drying process to ensure that it is within the desired range.

- Kiln temperature and humidity: The temperature and humidity inside the kiln need to be precisely controlled to achieve the desired drying conditions for the specific type of lumber being dried. I use sensors and control systems to maintain the optimal conditions throughout the process.

- Airflow: Proper airflow within the kiln is essential for even drying and to prevent moisture buildup. I monitor and adjust the airflow to ensure that it is adequate and consistent.

2. How do you monitor and control the drying process?

Monitoring the drying process

- Moisture content: I use moisture meters to regularly check the moisture content of the lumber at various points within the kiln. This allows me to track the progress of the drying process and make any necessary adjustments.

- Temperature and humidity: I monitor the temperature and humidity inside the kiln using sensors and control systems. This enables me to maintain the desired drying conditions and ensure that the lumber is drying evenly.

- Airflow: I observe the airflow patterns within the kiln and make adjustments to the fans and vents as needed to ensure adequate and consistent airflow.

Controlling the drying process

- Adjusting temperature and humidity: If the temperature or humidity is not within the desired range, I adjust the settings on the kiln’s control system to bring them back to the optimal levels.

- Optimizing airflow: I monitor the airflow and make adjustments to the fan speeds and vent settings to ensure that the airflow is evenly distributed throughout the kiln.

3. What are some common problems you have encountered in operating a lumber kiln?

- Uneven drying: This can occur due to factors such as poor airflow or inconsistent temperature and humidity levels within the kiln. I address this by adjusting the airflow and kiln settings to ensure uniform drying.

- Surface checking: This is a condition where the surface of the lumber develops small cracks. It can be caused by rapid drying or excessive drying temperatures. I prevent this by gradually increasing the temperature and humidity levels during the drying process and by monitoring the drying rate.

- Warping or twisting: This can happen if the lumber is not properly stacked or if the drying conditions are not controlled properly. I prevent warping and twisting by ensuring that the lumber is stacked securely and by monitoring the kiln conditions to maintain the desired drying rate.

4. What are your quality control procedures for ensuring that the lumber meets specifications?

- Moisture content testing: I conduct regular moisture content tests on the lumber throughout the drying process to ensure that it meets the specified moisture content range.

- Visual inspection: I visually inspect the lumber for any defects, such as surface checks, warping, or discoloration. This allows me to identify and remove any defective pieces before they are shipped to customers.

- Grading: I grade the lumber according to industry standards to ensure that it meets the required quality specifications.

5. What is your experience with kiln schedules?

- I am familiar with various kiln schedules for different types of lumber. I understand the importance of following the correct schedule to achieve the desired drying results.

- I have experience in developing and implementing custom kiln schedules to meet specific customer requirements.

- I am proficient in using kiln control systems to accurately implement and monitor kiln schedules.

6. How do you stay up-to-date with the latest industry standards and best practices?

- Attend industry conferences and seminars: I regularly attend industry events to gain knowledge about the latest technologies, best practices, and regulatory updates.

- Read industry publications: I subscribe to trade magazines and journals to stay informed about the latest research and advancements in the field of lumber drying.

- Network with other professionals: I actively participate in industry organizations and online forums to connect with other lumber kiln operators and exchange knowledge.

7. What are your goals for this role?

- My goal is to contribute my skills and experience to ensure the efficient and high-quality operation of the lumber kiln.

- I am eager to learn from experienced professionals and implement innovative practices to improve the kiln’s performance.

- I am confident that I can make a significant contribution to your team and help the company achieve its production goals.

8. How do you handle working in a fast-paced environment?

- I thrive in fast-paced environments and am able to prioritize tasks, manage my time effectively, and meet deadlines.

- I am comfortable working independently and as part of a team, and I am always willing to help out my colleagues.

- I am adaptable and can quickly adjust to changing priorities and unexpected situations.

9. How do you ensure safety in the workplace?

- I am committed to maintaining a safe work environment and follow all safety protocols and procedures.

- I am aware of the potential hazards associated with operating a lumber kiln and take necessary precautions to minimize risks.

- I regularly inspect equipment and work areas to identify and address any potential safety concerns.

10. What are your strengths and weaknesses as a lumber kiln operator?

Strengths

- Expertise in operating and maintaining lumber kilns

- Strong understanding of kiln schedules and drying processes

- Excellent troubleshooting skills and ability to resolve technical issues

- Commitment to quality control and meeting customer specifications

- Proven ability to work independently and as part of a team

Weaknesses

- Limited experience with certain types of exotic or specialty lumber

- Working extended hours during peak season can sometimes be challenging

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lumber Kiln Operator is responsible for operating and monitoring kilns that dry lumber. They maintain equipment, control temperature and humidity levels, and ensure that lumber is dried to the desired moisture content. Key job responsibilities include:

1. Operating Kilns

Kiln operators are responsible for operating and monitoring kilns to dry lumber. They must be familiar with the different types of kilns and their operation. They must also be able to control temperature and humidity levels to ensure that lumber is dried to the correct moisture content.

- Loading and unloading kilns

- Monitoring temperature and humidity levels

- Adjusting settings to maintain optimal conditions

2. Maintaining Equipment

Kiln operators are also responsible for maintaining equipment. They must be able to identify and fix problems with kilns, fans, and other equipment. They must also keep records of maintenance and repairs.

- Cleaning and lubricating equipment

- Inspecting equipment for damage

- Repairing or replacing equipment

3. Quality Control

Kiln operators are responsible for ensuring that lumber is dried to the correct moisture content. They must inspect lumber before and after it is dried to ensure that it meets quality standards.

- Measuring moisture content of lumber

- Grading lumber according to quality

- Rejecting lumber that does not meet standards

4. Safety

Kiln operators must follow safety procedures to protect themselves and others. They must wear appropriate protective clothing and equipment, and they must be aware of the potential hazards associated with working with kilns.

- Following safety procedures

- Using proper protective equipment

- Being aware of potential hazards

Interview Tips

Preparing for an interview for a Lumber Kiln Operator position can be daunting, but with the right tips and strategies, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also give you a better idea of what the job entails. You can find information about the company on its website, social media pages, and Glassdoor.

- Visit the company website

- Read the job description carefully

- Research the company’s industry

- Check out the company’s social media pages

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- “Tell me about yourself.”

For example: “I have been working in the lumber industry for the past five years, and I have experience operating and maintaining all types of kilns. I am also familiar with the different grades of lumber, and I am able to inspect lumber to ensure that it meets quality standards.”

- “Why are you interested in this position?”

For example: “I am interested in this position because I am looking for a challenging and rewarding career in the lumber industry. I am confident that I have the skills and experience necessary to be successful in this role, and I am eager to learn more about your company and the position.”

3. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are a hard worker. Be sure to make eye contact, smile, and speak clearly and concisely.

- Make eye contact

- Smile

- Speak clearly and concisely

- Dress professionally

- Arrive on time

4. Follow Up

After your interview, be sure to follow up with the interviewer. This could involve sending a thank-you note or email, or calling the interviewer to check on the status of your application. Following up shows the interviewer that you are interested in the position and that you are serious about getting the job.

- Send a thank-you note or email

- Call the interviewer to check on the status of your application

- Be patient

- Don’t be discouraged if you don’t get the job right away

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lumber Kiln Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.