Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lumber Tailer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

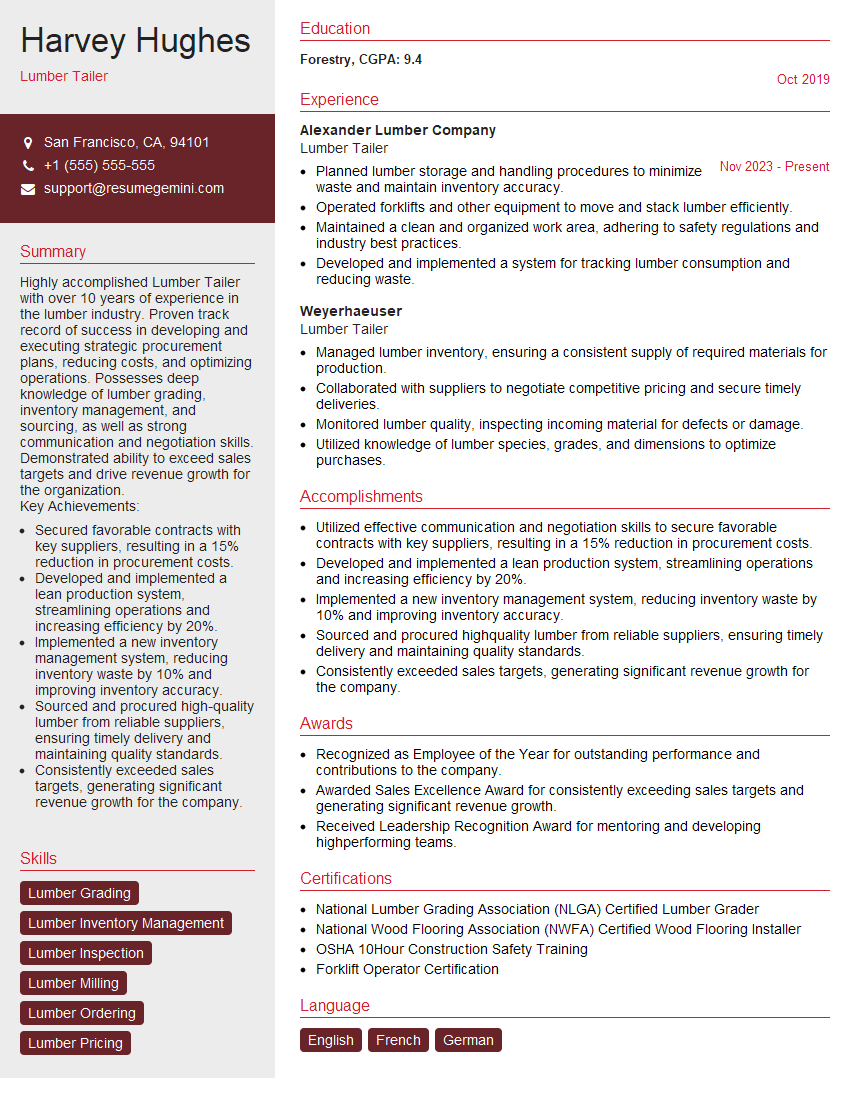

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Tailer

1. What are the different types of lumber and their uses?

There are many different types of lumber, each with its own unique properties and uses. Some of the most common types of lumber include:

- Softwood: Softwood is typically lightweight and easy to work with. It is often used for framing, sheathing, and other structural applications. Some common types of softwood include pine, fir, and spruce.

- Hardwood: Hardwood is typically heavier and more durable than softwood. It is often used for flooring, furniture, and other high-end applications. Some common types of hardwood include oak, maple, and cherry.

- Engineered lumber: Engineered lumber is a type of lumber that is manufactured from wood fibers. It is often used for applications where strength and durability are important, such as in bridges and beams. Some common types of engineered lumber include laminated veneer lumber (LVL) and oriented strand board (OSB).

2. What are the different grades of lumber?

Lumber is graded according to its appearance and strength. The higher the grade, the better the quality of the lumber. Some of the most common lumber grades include:

Select

- Clear: Clear lumber is free of knots, defects, and other imperfections.

- Select: Select lumber has a few small knots and other minor defects.

Common

- 1 Common: 1 Common lumber has a few small knots and other minor defects, but is still suitable for most applications.

- 2 Common: 2 Common lumber has more knots and defects than 1 Common lumber, but is still suitable for some applications, such as framing.

- 3 Common: 3 Common lumber has the most knots and defects of any grade of lumber, and is typically only used for rough construction.

3. How do you measure lumber?

Lumber is measured in board feet. A board foot is equal to one square foot of lumber that is one inch thick. To calculate the board footage of a piece of lumber, multiply the length by the width by the thickness. For example, a 2x4x8 board would have 16 board feet.

4. How do you cut lumber?

Lumber can be cut using a variety of tools, including saws, miter saws, and table saws. The type of saw that you use will depend on the type of cut that you need to make. For example, a miter saw is used to make angled cuts, while a table saw is used to make straight cuts.

5. How do you join lumber?

Lumber can be joined using a variety of methods, including nails, screws, and glue. The type of joint that you use will depend on the strength and durability that you need. For example, nails are a good choice for framing applications, while screws are a good choice for furniture applications.

6. How do you finish lumber?

Lumber can be finished using a variety of methods, including staining, painting, and varnishing. The type of finish that you use will depend on the desired look and protection that you need. For example, a stain is a good choice for highlighting the natural grain of the wood, while a varnish is a good choice for protecting the wood from the elements.

7. What are the safety precautions that you need to take when working with lumber?

There are a number of safety precautions that you need to take when working with lumber, including:

- Wear eye protection and ear protection.

- Be aware of your surroundings and keep your work area clean.

- Use sharp tools and keep them in good condition.

- Do not overload your tools.

- Be careful when lifting heavy objects.

8. What are the common problems that you may encounter when working with lumber?

There are a number of common problems that you may encounter when working with lumber, including:

- Warping: Warping is a condition that occurs when lumber bends or twists. Warping can be caused by changes in temperature or humidity.

- Splitting: Splitting is a condition that occurs when lumber cracks or breaks. Splitting can be caused by improper drying or handling.

- Rot: Rot is a condition that occurs when lumber is damaged by fungus or bacteria. Rot can be caused by exposure to moisture.

- Insects: Insects can damage lumber by boring holes or eating the wood. Insects can be prevented by using insecticides or by sealing the lumber.

9. What are the different types of lumber treatments?

There are a number of different lumber treatments that can be used to protect lumber from damage. Some of the most common lumber treatments include:

- Pressure-treated lumber: Pressure-treated lumber is treated with a chemical preservative that helps to protect the lumber from rot and insects.

- Fire-retardant lumber: Fire-retardant lumber is treated with a chemical that helps to slow the spread of fire.

- Weather-resistant lumber: Weather-resistant lumber is treated with a chemical that helps to protect the lumber from the elements.

10. What are the different types of lumber grades that are available for retail customers?

There are a number of different lumber grades that are available for retail customers, including:

- Select: Select lumber is the highest quality lumber that is available. It is free of knots and other defects.

- Common: Common lumber is a good choice for general construction purposes. It may have some knots and other defects, but it is still strong and durable.

- Utility: Utility lumber is the lowest quality lumber that is available. It may have large knots and other defects, but it is still suitable for some applications, such as framing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Tailer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Tailer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lumber tailers play a crucial role in lumber mills, converting raw logs into usable lumber products. Their primary responsibilities include:

1. Log Processing

Tailers operate heavy machinery such as sawmills and trimmers to cut logs into the desired lengths and thicknesses.

- Determine the optimal cutting pattern based on log characteristics.

- Operate saws and trimmers precisely to ensure accurate cuts and minimize waste.

2. Lumber Inspection and Sorting

Tailers inspect the cut lumber for defects, such as knots, cracks, or warping. They also sort the lumber based on quality and species.

- Use visual inspection techniques to identify defects and grade lumber.

- Group lumber according to specific standards and specifications.

3. Machine Maintenance and Troubleshooting

Maintaining and troubleshooting lumber processing machinery is crucial to ensure seamless operation.

- Conduct routine inspections and repairs on sawmills, trimmers, and other equipment.

- Identify and resolve mechanical issues to minimize downtime and optimize productivity.

4. Safety and Compliance

Lumber tailers prioritize safety in the workplace and adhere to industry regulations.

- Follow all safety protocols and procedures, including wearing proper protective gear.

- Comply with environmental regulations related to lumber production and waste management.

Interview Tips

To ace your interview for a lumber tailer position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. Demonstrate your knowledge and enthusiasm for the lumber industry.

2. Prepare for Technical Questions

Be prepared to answer questions related to lumber processing, inspection techniques, and machine operations. Practice explaining your knowledge of different types of lumber and their properties.

3. Highlight Your Physical Abilities

Lumber tailing is a physically demanding job. Emphasize your strength, stamina, and ability to handle heavy equipment and materials.

4. Showcase Your Safety Mindset

Safety is paramount in the lumber industry. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

5. Practice Behavioral Interviewing

Behavioral interviewing questions focus on your past experiences. Prepare examples of situations where you demonstrated skills such as problem-solving, teamwork, and attention to detail.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lumber Tailer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lumber Tailer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.