Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lumber Tying Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

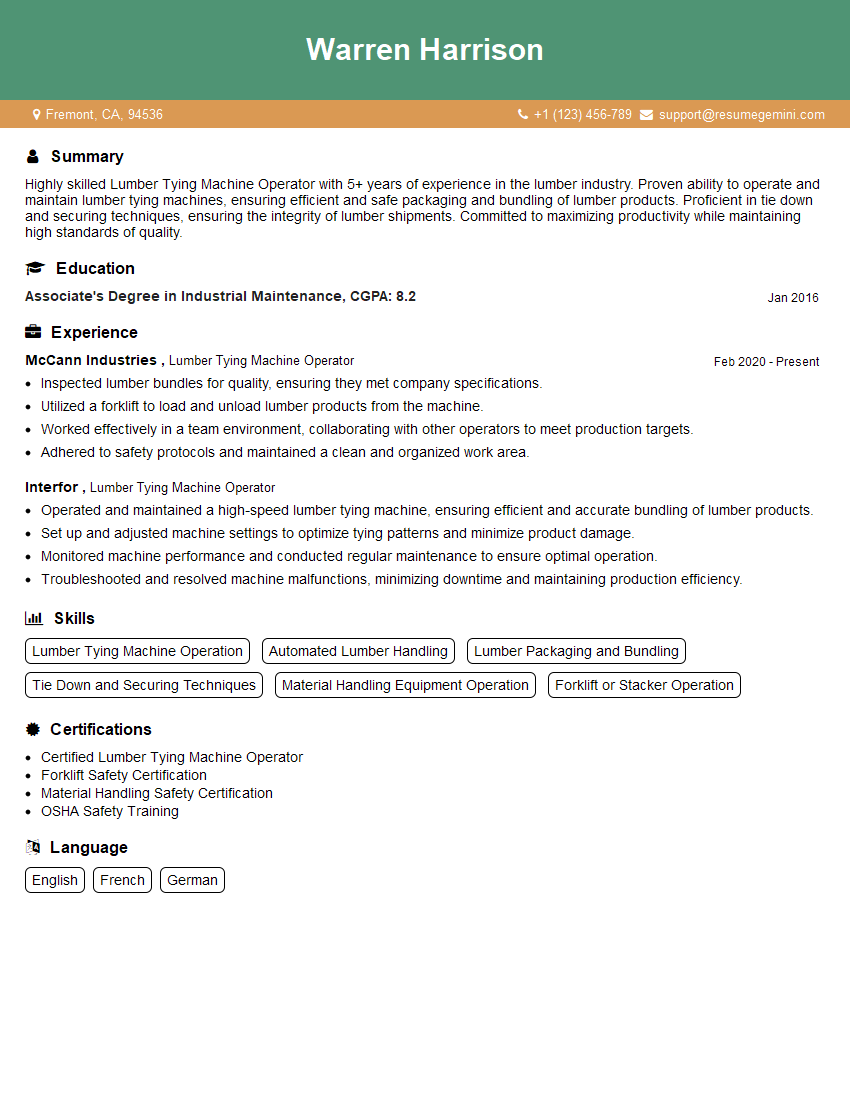

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lumber Tying Machine Operator

1. Explain the process of setting up a lumber tying machine?

- Gather necessary materials: lumber ties, strapping, and machine manual.

- Position the machine on a stable surface and connect it to the power source.

- Calibrate the machine: adjust the tension, speed, and settings as per the lumber specifications.

- Install the strapping and ties according to the machine’s instructions.

- Test the machine’s operation by running a few bundles of lumber.

2. Describe the different types of lumber bundles and how you handle them?

Softwood Bundles

- Typical sizes: 2×4, 2×6, 2×8

- Require minimal tension due to their flexibility

- Use wider straps to distribute pressure evenly

Hardwood Bundles

- Typical sizes: oak, maple, cherry

- Require higher tension due to their rigidity

- Use narrower straps to prevent damage to the wood

3. What are the common maintenance tasks you perform on a lumber tying machine?

- Regularly clean and lubricate components to prevent jams and ensure smooth operation.

- Inspect belts, sensors, and gears for any damage or wear and replace as needed.

- Monitor tension settings and adjust accordingly to maintain optimal tying quality.

- Troubleshoot and resolve any operational issues promptly to minimize downtime.

4. How do you ensure the safety and quality of the lumber tying process?

- Maintain a clean and well-organized work area to prevent slips and hazards.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Inspect lumber bundles for any defects or damage before tying.

- Monitor the machine’s performance closely to ensure optimal tension and spacing.

- Conduct regular quality checks on tied bundles to maintain consistency and meet standards.

5. What are the challenges you have faced as a Lumber Tying Machine Operator and how did you overcome them?

- Challenge: Machine malfunction causing production delays

- Solution: Prompt troubleshooting, identifying and replacing faulty parts

- Challenge: Varying lumber dimensions affecting tie quality

- Solution: Adjusting machine settings and using different strapping materials to accommodate

6. How do you stay updated on the latest industry best practices in lumber tying?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other operators and experts.

- Consult with manufacturers for product updates and training.

7. What is your experience with optimizing lumber tying machine performance?

- Regularly analyze machine performance data.

- Identify areas for improvement in speed, efficiency, and quality.

- Implement changes to machine settings, strapping materials, and maintenance practices.

- Monitor results and make further adjustments as needed.

8. How do you prioritize tasks and manage multiple responsibilities in a fast-paced environment?

- Maintain a clear understanding of job responsibilities.

- Develop a systematic approach to task prioritization.

- Delegate tasks when appropriate to ensure timely completion.

- Communicate effectively with colleagues and supervisors.

9. What is your understanding of the importance of teamwork in the lumber industry?

- Effective communication and coordination among team members.

- Sharing of knowledge and experiences to enhance overall performance.

- Collaboration to troubleshoot problems and find solutions.

- Teamwork contributes to increased productivity and efficiency.

10. How do you measure your success as a Lumber Tying Machine Operator?

- Consistent production of high-quality tied bundles.

- Minimization of machine downtime and maintenance issues.

- Positive feedback from customers and colleagues.

- Recognition for contributions to the team and overall production goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lumber Tying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lumber Tying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lumber Tying Machine Operator is responsible for the safe and efficient operation of the lumber tying machine to package and prepare lumber for storage and shipment at a lumber mill or manufacturing facility. The operator is responsible for ensuring the proper tension and alignment of the straps, as well as inspecting the finished product for quality.

1. Pre-Operational Checks

The operator is responsible for conducting pre-operational checks to ensure the machine is in good working order and that all safety measures are in place.

- Inspect the machine for any damage or wear and tear that could affect its operation.

- Check the oil and hydraulic fluid levels and add or replace as needed.

- Ensure that all guards and safety devices are in place and functioning properly.

2. Setup

Once the machine is ready for operation, the operator is responsible for setting up the machine to receive lumber.

- Place the lumber into the infeed conveyor and adjust the feed rate to ensure a steady and consistent flow of lumber.

- Set the strapping tension and alignment according to the specifications for the particular type and size of lumber being packaged.

- Ensure that the strapping material is loaded properly and that there is sufficient material available to complete the job.

3. Operation

With the machine properly setup, the operator is responsible for monitoring and controlling the operation of the lumber tying machine.

- Monitor the flow of lumber and adjust the feed rate as needed to ensure a smooth and efficient operation.

- Observe the strapping process and make adjustments to the tension and alignment as needed to ensure proper packaging.

- Unload the finished product from the outfeed conveyor and stack it according to the specifications for storage or shipment.

4. Maintenance

In addition to operating the machine, the operator is also responsible for performing basic maintenance and troubleshooting tasks.

- Clean the machine regularly to remove any sawdust or debris that could interfere with its operation.

- Lubricate the machine according to the manufacturer’s specifications.

- Inspect the strapping material for any damage or wear and tear and replace it as needed.

Interview Tips

Preparing for a job interview can be a daunting task, but by following a few simple tips, you can increase your chances of success.

1. Research the Company and Position

Before you go on an interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture and goals, as well as the specific requirements of the job. You can find information about the company on their website, in articles, and on social media. You can also find information about the position by reading the job description and talking to people who work in the industry.

- Learn about the company’s history, mission, values, and products or services.

- Identify the key responsibilities and qualifications for the position you are applying for.

- Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

2. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company and industry. You should also avoid wearing anything that is too revealing or too casual.

- Choose clothes that are clean, pressed, and fit well.

- Avoid wearing anything that is too revealing or too casual.

- Consider the company’s culture and industry when choosing your outfit.

3. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job. If you are running late, call or email the interviewer to let them know.

- Plan your route in advance and leave yourself plenty of time to get to the interview.

- If you are running late, call or email the interviewer to let them know.

- Be prepared to explain why you were late, but keep it brief and professional.

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine, and let your personality shine through.

- Be honest and genuine in your answers.

- Let your personality shine through.

- Don’t try to be someone you’re not.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lumber Tying Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.