Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lump Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

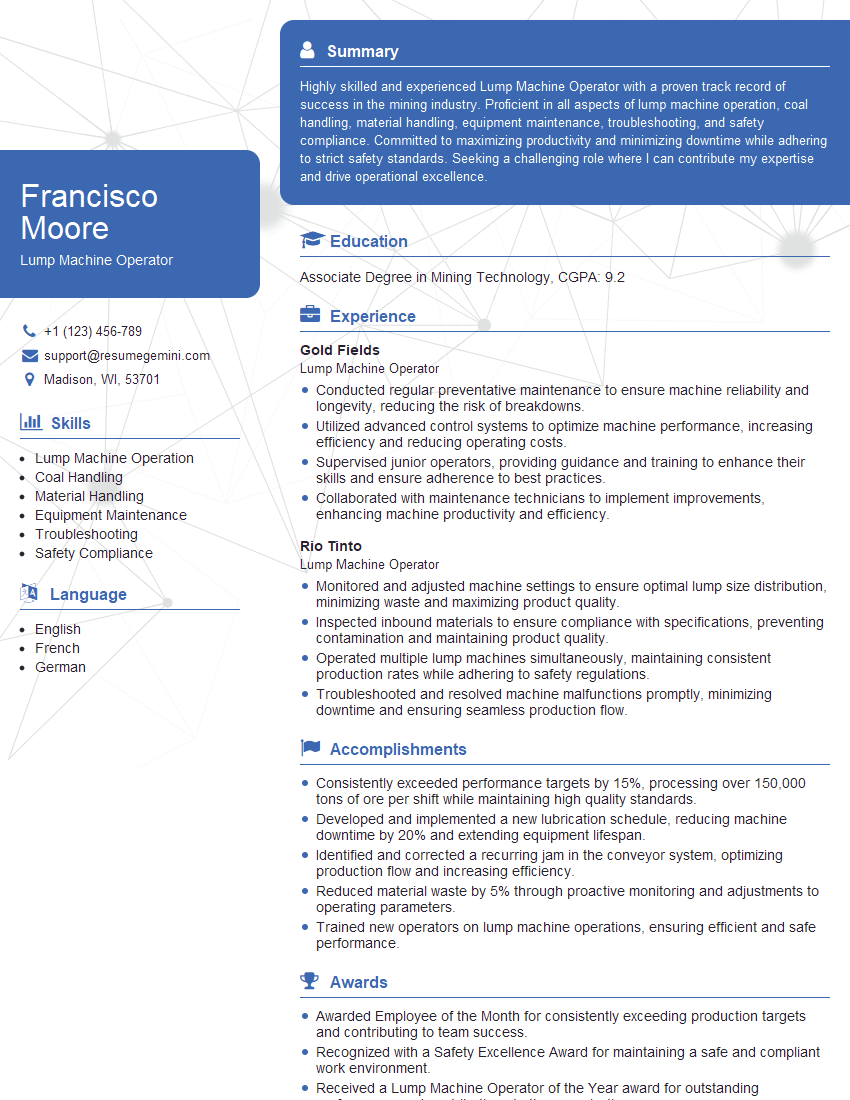

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lump Machine Operator

1. How do you handle a lump machine when it is not producing lumps of the correct size?

As a Lump Machine Operator, I would troubleshoot the issue by following these steps:

- Inspect the raw material to ensure it meets the required specifications.

- Check for blockages or obstructions in the feed hopper or discharge chute.

- Examine the cutting blades for signs of wear or damage, as dull blades can impact the lump size.

- Verify that the machine settings, such as cutting speed and feed rate, are adjusted appropriately for the desired lump size.

- If necessary, consult the manufacturer’s manual or seek technical support to resolve the issue.

2. What steps do you take to ensure the safety of yourself and others while operating a lump machine?

Safe Operation Practices

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Keep a safe distance from moving parts and rotating machinery.

- Never reach into the machine while it is operating.

- Be aware of the potential for dust, noise, and other hazards.

Emergency Procedures

- Know the location of emergency stop buttons and use them immediately in case of any malfunction or hazard.

- Follow established evacuation procedures and report any accidents or incidents promptly.

3. How would you respond to an unexpected shutdown of the lump machine during operation?

In case of an unexpected shutdown, I would:

- Immediately press the emergency stop button to ensure safety.

- Identify the cause of the shutdown, such as power failure, mechanical malfunction, or raw material supply issue.

- If possible, attempt to restart the machine following proper procedures.

- If the problem persists, contact the supervisor or maintenance team for assistance.

- Document the incident, including the time, date, and any relevant observations.

4. What techniques do you use to maximize the efficiency of a lump machine?

To maximize efficiency, I would employ the following techniques:

- Ensure the machine is properly calibrated and maintained.

- Optimize machine settings based on the raw material and desired lump size.

- Monitor production output and adjust parameters as needed.

- Minimize downtime by promptly addressing any issues or blockages.

- Follow manufacturer’s guidelines and best practices to improve overall performance.

5. What strategies do you use to minimize waste and ensure product quality during lump machine operation?

To minimize waste and ensure product quality, I would:

- Inspect the raw material before feeding it into the machine to remove impurities or damaged pieces.

- Control the feed rate and cutting speed to produce lumps of uniform size and shape.

- Regularly monitor the cutting blades and replace them when necessary to maintain sharp edges.

- Screen the produced lumps to remove any oversized or undersized pieces.

- Follow established quality control procedures to ensure the lumps meet specifications.

6. How do you handle situations where the lump machine produces lumps that are not meeting the desired quality standards?

If the lump machine is not producing lumps of the desired quality, I would:

- Identify the root cause of the issue, such as worn blades, incorrect settings, or feed material problems.

- Adjust machine settings, replace blades, or modify feed material as necessary.

- Monitor the output and make further adjustments until the desired quality is achieved.

- Contact the supervisor or maintenance team if the issue cannot be resolved.

- Document any changes made to the machine or process.

7. What preventive maintenance tasks do you perform to ensure the smooth operation of a lump machine?

To ensure smooth operation, I would perform the following preventive maintenance tasks:

- Regularly clean and lubricate all moving parts.

- Inspect cutting blades for wear and replace them as needed.

- Check belts and chains for tension and replace them if necessary.

- Monitor oil levels and top up as required.

- Follow manufacturer’s recommended maintenance schedule.

8. How do you prioritize your tasks when working as part of a team in a lump machine operation?

When working in a team, I prioritize my tasks based on the following factors:

- Urgency: Addressing critical or time-sensitive tasks first.

- Impact: Prioritizing tasks that have a significant impact on production or quality.

- Dependencies: Completing tasks that are essential for other team members to continue their work.

- Workload: Distributing tasks fairly among team members to ensure an even workload.

- Communication: Regularly communicating with the team to stay informed about progress and any changes in priorities.

9. How do you maintain a clean and organized work area around a lump machine?

To maintain a clean and organized work area, I would:

- Regularly sweep and remove any debris or spillage.

- Keep tools and materials organized and easily accessible.

- Clean the machine and its surroundings after each shift.

- Dispose of waste materials properly.

- Monitor for leaks or spills and address them promptly.

10. How do you stay up-to-date with the latest advancements in lump machine technology and industry best practices?

To stay up-to-date, I would:

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and industry experts.

- Continuously seek opportunities to learn and improve my knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lump Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lump Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lump Machine Operators are responsible for operating and maintaining lump machines.

1. Monitor Production

Monitor lump machine production to ensure optimal performance.

- Observe machine operations and identify any issues or inefficiencies.

- Adjust machine settings and parameters to maximize production efficiency.

2. Maintain Equipment

Perform routine maintenance and repairs on lump machines.

- Clean and lubricate machine components to prevent breakdowns.

- Inspect equipment for wear and tear and replace or repair parts as needed.

3. Ensure Safety

Follow all safety protocols and wear appropriate protective gear.

- Operate machinery safely and responsibly.

- Identify potential hazards and take steps to mitigate risks.

4. Quality Assurance

Monitor and control the quality of products produced by the lump machine.

- Inspect final products for defects or inconsistencies.

- Identify and correct any production issues that affect product quality.

Interview Tips

Preparing for a Lump Machine Operator interview requires a combination of technical knowledge, safety awareness, and an understanding of the industry.

1. Research the Role and Company

Familiarize yourself with the responsibilities of a Lump Machine Operator and the specific requirements of the role you are applying for.

- Review the job description and identify the key skills and qualifications required.

- Research the company’s industry, products, and values to demonstrate your alignment with their goals.

2. Highlight Technical Skills

Emphasize your technical abilities in operating and maintaining lump machines.

- Describe your experience with different types of lump machines and the specific tasks you have performed.

- Quantify your accomplishments with metrics, such as increased production efficiency or reduced downtime.

3. Focus on Safety

Convey your strong commitment to safety and adherence to all safety protocols.

- Explain your understanding of the safety hazards associated with lump machine operation.

- Describe your experience in implementing safety procedures and managing potential risks.

4. Demonstrate Quality Assurance

Showcase your attention to detail and commitment to producing high-quality products.

- Provide examples of your ability to identify and resolve production issues that affect product quality.

- Discuss any quality control measures you have implemented to improve production efficiency.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lump Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!