Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lye Peel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

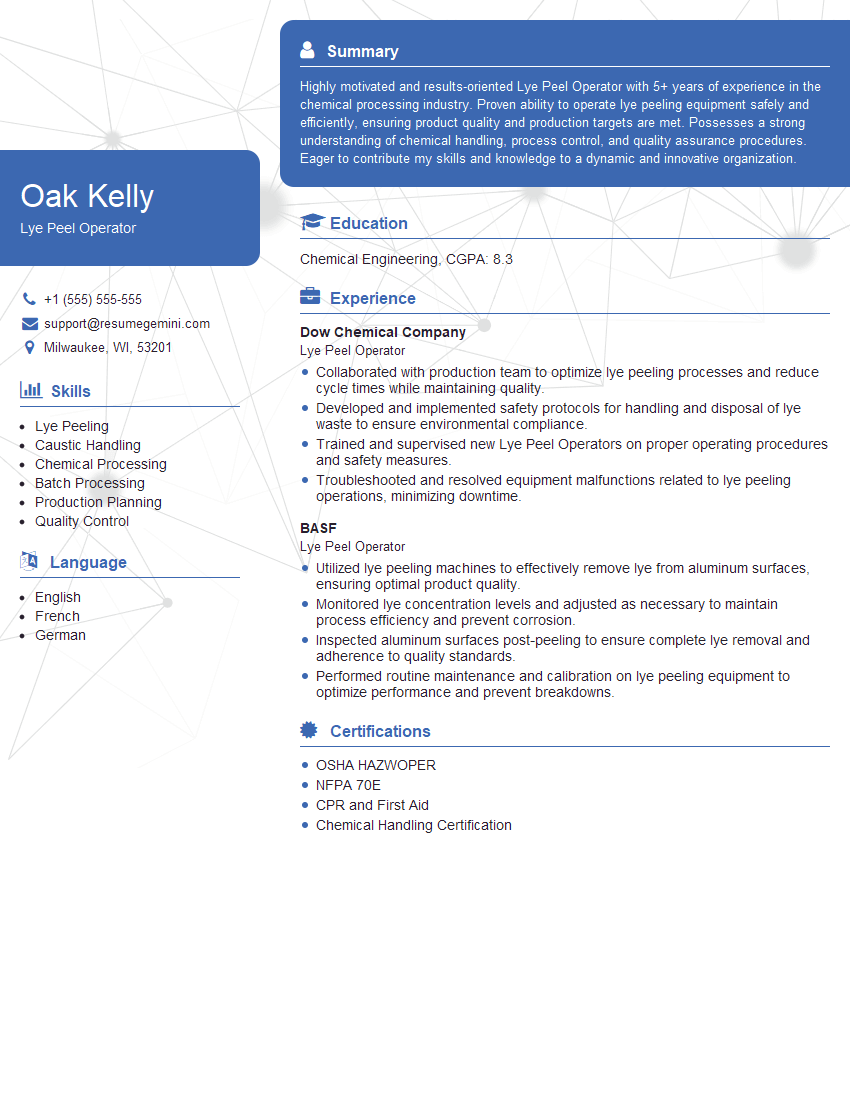

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lye Peel Operator

1. What are the key responsibilities of a Lye Peel Operator?

- Operate and maintain lye peel machines to remove excess sodium hydroxide from textile fabrics

- Monitor and adjust machine settings to ensure optimal performance and product quality

- Troubleshoot and resolve machine malfunctions and breakdowns

- Follow established safety protocols and maintain a clean and organized work area

- Coordinate with other team members and supervisors to ensure smooth production operations

2. What types of lye peel machines have you worked with in the past?

- Batch lye peel machines

- Continuous lye peel machines

- Open-width lye peel machines

- Pad-batch lye peel machines

3. How do you determine the appropriate lye concentration and application time for different types of fabrics?

- Review fabric specifications and consult with technical experts

- Conduct laboratory tests to determine optimal parameters

- Adjust lye concentration and application time based on fabric type, weight, and desired level of scouring

- Monitor fabric quality and make adjustments as needed to ensure consistent results

4. What are the potential hazards associated with working with lye solutions?

- Chemical burns to skin and eyes

- Respiratory irritation

- Fires and explosions

- Environmental contamination

5. How do you mitigate the risks associated with working with lye solutions?

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and a respirator

- Handle lye solutions with care and avoid spills

- Store lye solutions in designated areas away from incompatible materials

- Follow established safety protocols and procedures

- Receive regular training on lye handling and safety

6. What are the common problems that can occur during lye peeling and how do you resolve them?

- Fabric damage: Adjust lye concentration or application time, check machine settings

- Insufficient scouring: Increase lye concentration or application time, check machine temperature

- Uneven lye application: Check machine nozzles and ensure uniform distribution of lye solution

- Machine breakdowns: Troubleshoot and repair mechanical or electrical issues, contact maintenance personnel if necessary

7. How do you maintain and calibrate lye peel machines to ensure their accuracy and efficiency?

- Follow manufacturer’s maintenance schedule for regular cleaning, lubrication, and inspections

- Calibrate sensors and controllers to ensure accurate lye concentration and application

- Monitor machine performance and make adjustments as needed to maintain optimal efficiency

- Keep records of maintenance and calibration activities

8. What quality control measures do you implement to ensure that the lye peeling process meets desired standards?

- Monitor fabric quality throughout the process, including visual inspections and laboratory testing

- Establish and maintain quality control standards for fabric appearance, strength, and other relevant parameters

- Document and record quality control data for traceability and continuous improvement

- Work with quality assurance personnel to ensure compliance with industry standards

9. How do you prioritize your workload and manage multiple tasks in a fast-paced production environment?

- Plan and organize work schedule to ensure efficient use of time

- Prioritize tasks based on urgency and importance

- Delegate tasks to team members when appropriate

- Communicate effectively with colleagues and supervisors to coordinate activities

- Utilize technology and automation to streamline processes and save time

10. Describe a situation where you successfully identified and resolved a production issue related to lye peeling.

- Situation: Fabric was exhibiting uneven lye application and resulting in inconsistent scouring

- Actions: Checked machine nozzles for blockages, adjusted lye concentration and application time

- Resolution: Identified a clogged nozzle and replaced it, adjusted lye parameters to optimize scouring

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lye Peel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lye Peel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lye Peel Operators are responsible for overseeing the lye peeling process, which involves removing the skin from animal hides. They work in tanneries or other industrial settings where leather is produced.

1. Monitoring and controlling the lye peeling process

Lye Peel Operators must monitor and control the lye peeling process to ensure that the hides are properly treated. They must adjust the temperature, concentration, and agitation of the lye solution to achieve the desired results.

- Monitoring the temperature of the lye solution

- Adjusting the concentration of the lye solution

- Controlling the agitation of the lye solution

2. Inspecting hides

Lye Peel Operators must inspect hides before and after the peeling process to ensure that they are free of defects. They must also identify any hides that are not suitable for peeling.

- Inspecting hides for defects

- Identifying hides that are not suitable for peeling

3. Maintaining equipment

Lye Peel Operators must maintain the equipment used in the lye peeling process. They must clean and lubricate the equipment, and they must also make repairs as needed.

- Cleaning and lubricating the equipment

- Making repairs as needed

4. Following safety procedures

Lye Peel Operators must follow all safety procedures when working with lye. They must wear protective clothing and equipment, and they must be aware of the potential hazards of working with lye.

- Wearing protective clothing and equipment

- Being aware of the potential hazards of working with lye

Interview Tips

To ace an interview for a Lye Peel Operator position, it is important to be prepared and to have a good understanding of the job responsibilities. Here are some tips for preparing for an interview:

1. Research the company and the position

Before going to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visiting the company’s website

- Reading articles about the company

- Talking to people who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Brainstorming a list of common interview questions

- Writing out your answers to these questions

- Practicing your answers out loud

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience in the lye peeling industry. Be prepared to talk about your specific skills and knowledge, and how they relate to the job requirements.

- Highlighting your experience with lye peeling

- Describing your skills and knowledge

- Explaining how your experience relates to the job requirements

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position. Be prepared to ask questions about the company’s culture, the specific requirements of the job, and the opportunities for advancement.

- Preparing a list of questions to ask the interviewer

- Asking questions about the company’s culture

- Asking questions about the specific requirements of the job

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lye Peel Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.