Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Adjuster Leader interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Adjuster Leader so you can tailor your answers to impress potential employers.

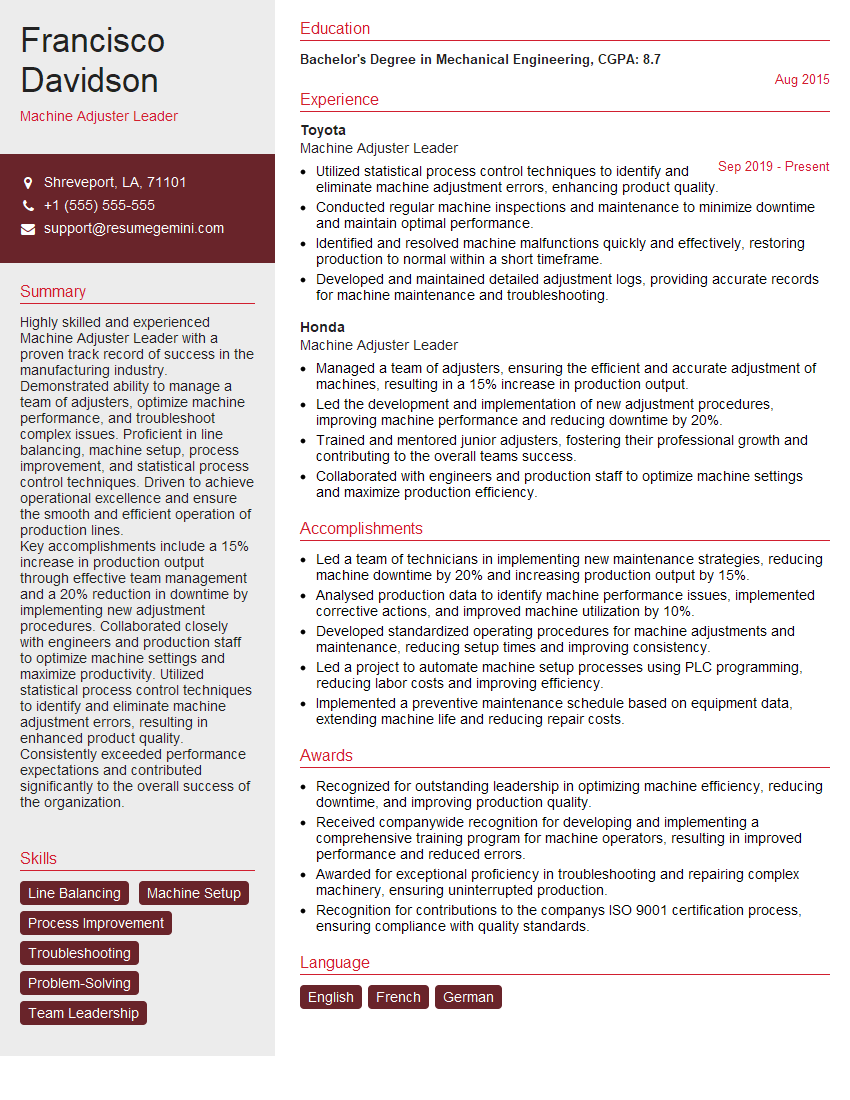

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Adjuster Leader

1. What are the key responsibilities of a Machine Adjuster Leader?

As a Machine Adjuster Leader, my key responsibilities include:

- Leading and supervising a team of machine adjusters

- Ensuring that all machines are operating at peak efficiency

- Identifying and resolving any production issues

- Training and developing new machine adjusters

- Maintaining a safe and productive work environment

2. What are the different types of machines that you have experience adjusting?

PLC controlled machines

- I have experience adjusting a variety of PLC controlled machines, including CNC machines, robots, and automated assembly lines.

Mechanical machines

- I have also worked with mechanical machines, such as presses, brakes, and shears.

3. What are some of the common problems that you have encountered when adjusting machines?

Some of the common problems that I have encountered when adjusting machines include:

- Misaligned components

- Incorrectly calibrated sensors

- Damaged or worn parts

- Electrical faults

- Software glitches

4. How do you troubleshoot and resolve machine problems?

I follow a systematic approach to troubleshooting and resolving machine problems:

- First, I gather information about the problem, including when it started, what symptoms are present, and what steps have been taken to resolve it.

- Next, I inspect the machine and its components to identify any obvious problems.

- If I can’t find the problem visually, I use diagnostic tools to further investigate the issue.

- Once I have identified the problem, I develop and implement a solution.

- Finally, I test the solution to ensure that it has resolved the problem.

5. What are some of the safety precautions that you take when adjusting machines?

I always take the following safety precautions when adjusting machines:

- I wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- I make sure that the machine is properly locked out and tagged out before I begin working on it.

- I use proper lifting techniques to move heavy objects.

- I am aware of the potential hazards of the machine and take steps to avoid them.

6. What are some of the quality control measures that you use to ensure that machines are operating properly?

I use the following quality control measures to ensure that machines are operating properly:

- I inspect all machines on a regular basis to identify any potential problems.

- I use precision measuring tools to ensure that machines are producing parts to the correct specifications.

- I maintain a log of all maintenance and repairs performed on machines.

- I work with the quality control department to develop and implement quality control procedures.

7. How do you train and develop new machine adjusters?

I use the following methods to train and develop new machine adjusters:

- I provide on-the-job training to new adjusters.

- I develop and deliver training programs on specific machine types and processes.

- I assign new adjusters to experienced mentors.

- I provide feedback and coaching to new adjusters on a regular basis.

8. What are some of the challenges that you have faced as a Machine Adjuster Leader?

Some of the challenges that I have faced as a Machine Adjuster Leader include:

- Keeping up with the latest technology

- Managing a team of employees with different skill levels

- Meeting production goals while maintaining quality standards

- Dealing with unexpected breakdowns and emergencies

9. What are your strengths as a Machine Adjuster Leader?

My strengths as a Machine Adjuster Leader include:

- My technical expertise in machine adjustment and repair

- My ability to lead and motivate a team of employees

- My commitment to safety and quality

- My ability to solve problems and make decisions under pressure

- My willingness to learn and grow

10. What are your career goals?

My career goal is to become a Production Manager. I believe that my skills and experience as a Machine Adjuster Leader have prepared me for this role. I am confident that I can lead a production team to achieve its goals while maintaining high standards of quality and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Adjuster Leader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Adjuster Leader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Adjuster Leaders play a crucial role in manufacturing environments by overseeing the setup, maintenance, and operation of complex machinery. Their primary responsibilities involve:

1. Machine Setup and Adjustment

Leaders ensure that machines are properly set up and adjusted to meet production requirements. They analyze specifications, identify necessary adjustments, and fine-tune settings for optimal performance.

2. Troubleshooting and Maintenance

They diagnose and troubleshoot machine malfunctions, identify root causes, and perform repairs. They also conduct preventive maintenance to minimize downtime and ensure machine longevity.

3. Process Optimization

Leaders analyze production processes to identify areas for improvement. They suggest and implement changes to optimize machine utilization, reduce waste, and enhance efficiency.

4. Quality Control

They enforce quality standards by monitoring production output and ensuring that products meet specifications. They participate in quality audits and implement corrective actions when necessary.

5. Team Leadership and Training

Leaders manage a team of Machine Adjusters, providing guidance, training, and performance feedback. They foster a positive and collaborative work environment.

Interview Tips

To ace an interview for a Machine Adjuster Leader position, consider the following tips:

1. Research the Company

Familiarize yourself with the company’s industry, products, and culture. This demonstrates your interest and preparedness.

2. Highlight Your Technical Skills

Emphasize your proficiency in machine setup, adjustment, troubleshooting, and maintenance. Provide specific examples of your experience.

3. Showcase Your Leadership Abilities

Highlight instances where you effectively led and motivated a team. Explain how you fostered collaboration and resolved conflicts.

4. Quantify Your Results

Use metrics to demonstrate the impact of your work. For example, quantify improvements in production efficiency, quality control, or downtime reduction.

5. Prepare for Technical Questions

Be prepared to answer technical questions about machine adjustment, troubleshooting, and process optimization. Practice answering questions in a clear and concise manner.

6. Ask Thoughtful Questions

Ask questions that demonstrate your interest and engagement. For example, inquire about the company’s future plans, the latest industry trends, or their approach to quality control.

7. Dress Professionally

First impressions matter. Dress professionally and arrive on time for the interview.

8. Be Enthusiastic

Convey your enthusiasm for the role and the company. This will help you stand out as a motivated and engaged candidate.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Adjuster Leader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!