Feeling lost in a sea of interview questions? Landed that dream interview for Machine Burrer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Burrer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

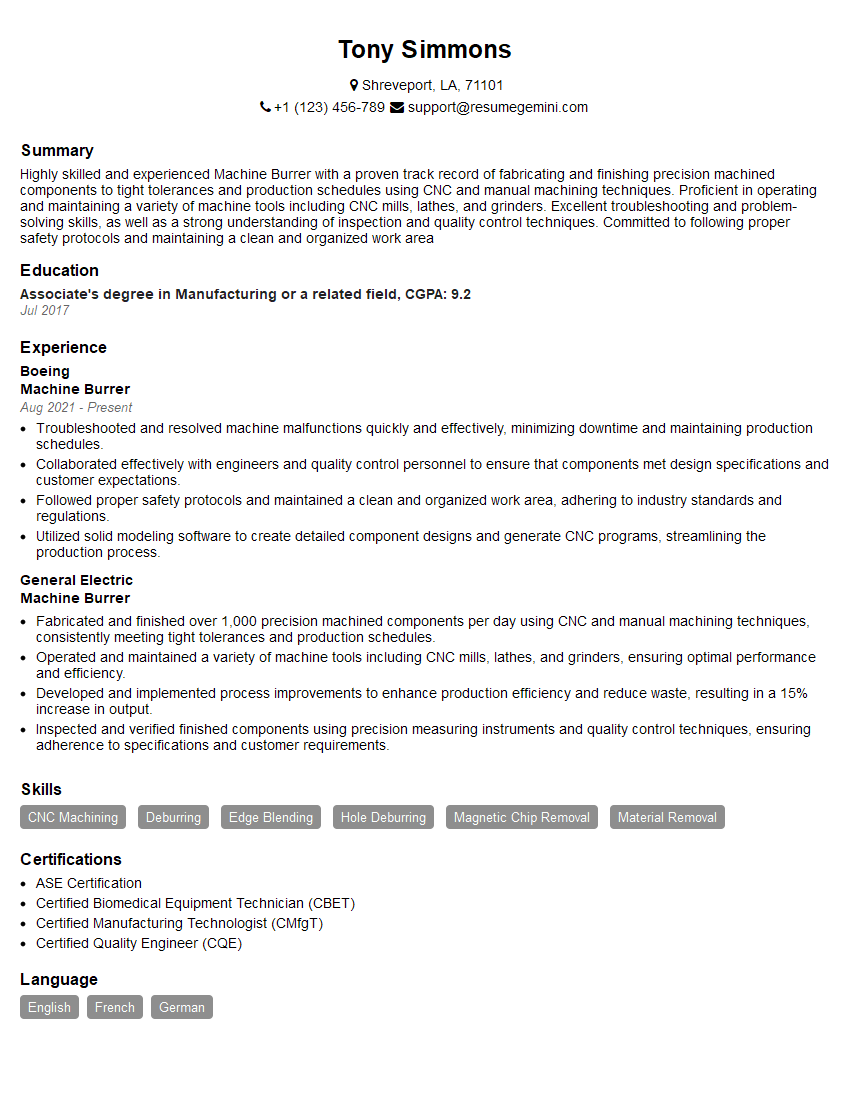

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Burrer

1. What are your key responsibilities as a Machine Burrer?

As a Machine Burrer, I am responsible for performing various burring operations on metal components using specialized machines. My duties include:

- Reading and understanding blueprints to determine burring requirements.

- Selecting and installing the appropriate burring tools and accessories.

- Operating machines to remove burrs from metal edges, holes, and surfaces.

- Inspecting the finished components to ensure they meet quality standards.

2. Describe the different types of burring tools and their uses.

Types of Burring Tools

- Rotary Brushes: Used for general-purpose deburring and edge rounding.

- Hand Burrs: Small, handheld tools for precise burr removal in tight spaces.

- Belt Sanders: Used for larger components or heavy-duty burring.

- Deburring Bits: Rotary tools with specialized bits for specific burr removal needs.

Uses of Burring Tools

- Removing sharp edges and burrs from machined parts.

- Preparing metal surfaces for welding, painting, or plating.

- Improving the appearance and safety of metal components.

3. How do you ensure the quality of your burring work?

I maintain the quality of my burring work through the following measures:

- Thoroughly inspecting components before and after burring to identify potential burrs.

- Using appropriate burring tools and techniques to minimize damage to the metal surface.

- Following established quality control procedures and specifications.

- Continuously monitoring burring operations and making adjustments as needed.

- Seeking feedback from team members and supervisors to identify areas for improvement.

4. What are the safety precautions you observe when operating burring machines?

To ensure a safe work environment, I adhere to the following safety precautions:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Keeping the work area clear and free of clutter.

- Inspecting machines and tools before each use to ensure they are in good working condition.

- Operating machines within their specified speed and capacity limits.

- Following lockout/tagout procedures when servicing or repairing equipment.

5. Can you describe a challenging burring project you worked on and how you overcame the difficulties?

Challenging Burring Project

I recently worked on a project involving the burring of intricate aluminum castings for an aerospace application. The castings had complex geometries and tight tolerances, making the burring process challenging.

Overcoming Difficulties

- Used a combination of hand burrs and rotary brushes to carefully remove burrs without damaging the fragile metal.

- Developed a specialized burring fixture to hold the castings securely and ensure precision.

- Collaborated with engineers to optimize the burring process and meet the project’s exacting requirements.

6. What are some of the common problems you encounter while burring and how do you address them?

Common Burring Problems

- Inconsistent burr removal.

- Damage to the metal surface.

- Excessive burr formation.

Problem-Solving Techniques

- Adjusting burring parameters such as speed, pressure, and tool selection.

- Using specialized burring tools or fixtures to improve precision and reduce damage.

- Consulting with supervisors or engineers for technical support and guidance.

7. How do you stay up-to-date with the latest burring technologies and best practices?

To stay current with industry trends and advancements, I engage in the following practices:

- Attending industry events, conferences, and training programs.

- Reading technical journals and articles related to burring.

- Consulting with equipment manufacturers and technical experts.

- Participating in online forums and discussions with other professionals.

8. How do you measure your productivity as a Machine Burrer?

I evaluate my productivity through the following metrics:

- Number of components burred per hour.

- Percentage of burr-free components produced.

- Time spent on quality control and rework.

- Feedback from supervisors and team members on overall efficiency.

9. How do you maintain and troubleshoot burring machines?

Machine Maintenance

- Regular cleaning and lubrication of machines.

- Inspection of components such as belts, brushes, and bearings.

- Replacement of worn or damaged parts as needed.

Troubleshooting

- Identify potential issues by observing machine operation and listening for unusual sounds or vibrations.

- Refer to technical manuals or consult with equipment manufacturers for guidance.

- Perform repairs or adjustments as necessary to restore machine functionality.

10. Why are you interested in joining our company as a Machine Burrer?

I am eager to join your company as a Machine Burrer because I am impressed by your reputation for excellence in manufacturing and your commitment to quality. I believe that my skills and experience in burring operations would be a valuable asset to your team. I am confident that I can contribute to the success of your company by delivering high-quality burring services.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Burrer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Burrer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Burrer is responsible for maintaining and operating machines that smooth and finish metal components. These professionals ensure that the final products meet the required specifications and quality standards.

1. Machine Operation

Operate machines that remove excess material from metal components using abrasive brushes or sanding belts.

2. Quality Control

Inspect finished parts to verify that they meet the specified dimensions, tolerances, and surface finishes.

3. Maintenance

Perform preventive maintenance and repairs on machines, including cleaning, lubricating, and adjusting components.

4. Setup

Set up and adjust machines according to the specific requirements of each job, including selecting and installing the appropriate tooling.

5. Materials Handling

Load and unload materials and finished parts from the machines, ensuring proper handling and storage.

Interview Preparation Tips

To ace an interview for a Machine Burrer position, follow these tips:

1. Research the Company

Learn about the company’s history, size, products, and markets. Understand their industry and their competitors.

2. Practice Your Answers

Prepare responses to common interview questions about your skills, experience, and motivation. Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight Your Skills and Experience

Emphasize your proficiency in operating and maintaining machine burring equipment. Mention specific instances where you have successfully resolved technical issues.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company.

Example Outline for Answers

When answering interview questions, use the following outline as a framework:

- Situation: Briefly describe the background or context of the situation.

- Task: Explain your role and responsibilities in the situation.

- Actions: Describe the specific actions you took to address the situation.

- Results: Quantify or qualify the outcomes of your actions, highlighting any achievements or improvements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Burrer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!