Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Castings Plasterer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

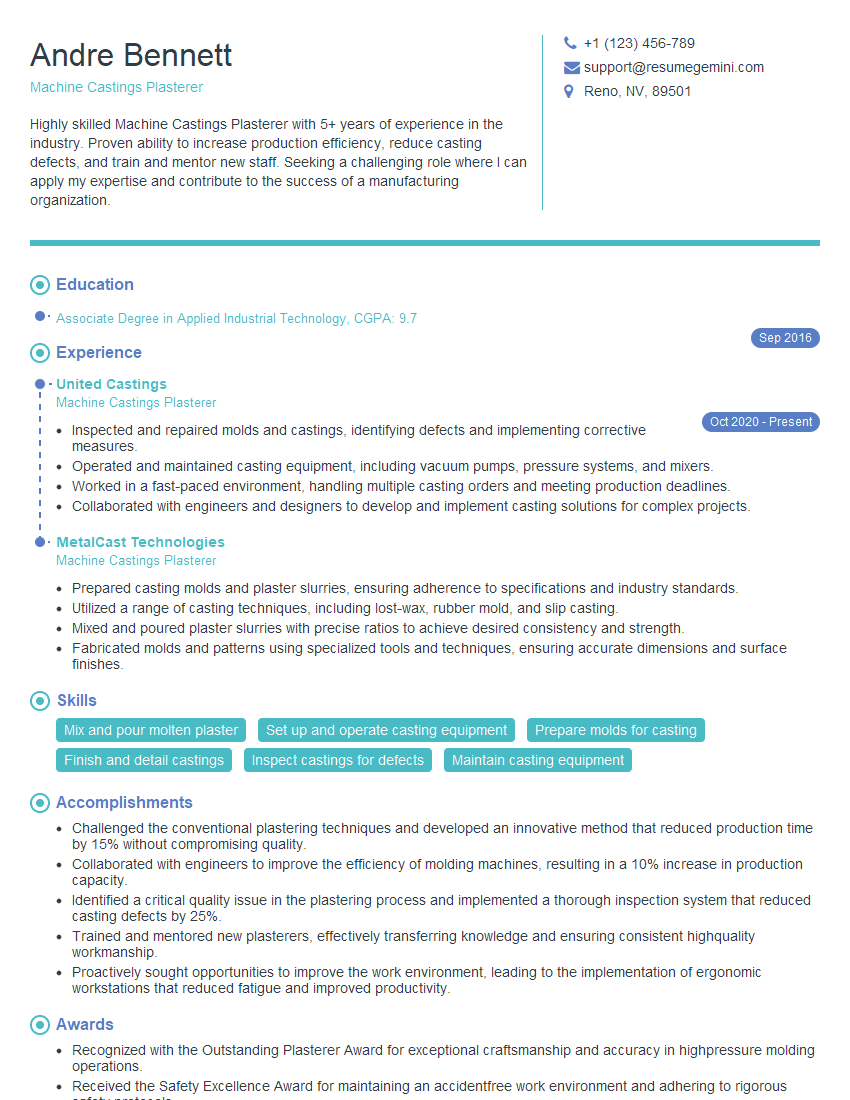

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Castings Plasterer

1. What are the different types of plaster used in machine castings?

There are two main types of plaster used in machine castings: gypsum plaster and cement plaster. Gypsum plaster is made from calcined gypsum, which is a naturally occurring mineral. Cement plaster is made from Portland cement, which is a man-made material. Both types of plaster have their own advantages and disadvantages.

- Gypsum plaster is stronger and more durable than cement plaster. It is also less likely to crack or shrink. However, it is more expensive than cement plaster and can be more difficult to work with.

- Cement plaster is less expensive than gypsum plaster and is easier to work with. However, it is not as strong or durable as gypsum plaster and is more likely to crack or shrink.

2. What are the different types of machines used in machine castings?

Casting machines

- These machines are used to create the plaster molds for machine castings.

- The most common types of casting machines are vacuum casting machines and centrifugal casting machines.

Coating machines

- These machines are used to apply a coating to the plaster molds to prevent them from absorbing moisture.

- The most common types of coating machines are dip coating machines and spray coating machines.

Molding machines

- These machines are used to form the plaster molds around the patterns.

- The most common types of molding machines are jolt molding machines and squeeze molding machines.

3. What are the different steps involved in machine castings?

The following are the general steps involved in machine castings:

- Create a pattern for the casting.

- Make a plaster mold from the pattern.

- Apply a coating to the plaster mold.

- Form the plaster mold around the pattern.

- Remove the pattern from the plaster mold.

- Pour molten metal into the plaster mold.

- Allow the metal to cool and solidify.

- Remove the casting from the plaster mold.

- Finish the casting.

4. What are the different factors that affect the quality of machine castings?

The following are some of the factors that can affect the quality of machine castings:

- The quality of the pattern

- The quality of the plaster mold

- The quality of the coating

- The pouring temperature of the metal

- The cooling rate of the metal

- The skill of the caster

5. What are the different defects that can occur in machine castings?

The following are some of the most common defects that can occur in machine castings:

- Shrinkage porosity

- Gas porosity

- Cracking

- Warpage

- Inclusions

6. How can you prevent defects from occurring in machine castings?

There are a number of steps that can be taken to prevent defects from occurring in machine castings. These steps include:

- Using high-quality patterns and molds

- Applying a proper coating to the molds

- Pouring the metal at the correct temperature

- Cooling the metal at a controlled rate

- Properly training casters

7. What are the different safety precautions that should be taken when working with machine castings?

The following are some of the most important safety precautions that should be taken when working with machine castings:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Handle molten metal with care.

- Be aware of the potential for explosions when working with molten metal.

- Keep the work area clean and free of debris.

- Follow all safety procedures and regulations.

8. What are the different maintenance tasks that need to be performed on machine casting equipment?

The following are some of the most important maintenance tasks that need to be performed on machine casting equipment:

- Clean and inspect the equipment regularly.

- Lubricate moving parts.

- Calibrate the equipment regularly.

- Repair or replace worn or damaged parts.

- Follow all manufacturer’s instructions for maintenance.

9. What are the different troubleshooting tips for machine casting problems?

The following are some general troubleshooting tips for machine casting problems:

- If the casting is not filling out properly, check the pouring temperature of the metal.

- If the casting has porosity, check the quality of the mold and the coating.

- If the casting has cracks, check the cooling rate of the metal.

- If the casting has warpage, check the pattern and the mold.

- If the casting has inclusions, check the quality of the metal.

10. What are the different career opportunities for machine casting plasterers?

There are a number of different career opportunities for machine casting plasterers. Some of these opportunities include:

- Working in a foundry

- Working in a machine shop

- Working in a construction company

- Working in a manufacturing plant

- Starting your own business

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Castings Plasterer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Castings Plasterer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Castings Plasterers are responsible for making and maintaining plaster molds used in the production of metal castings. They work with a variety of materials, including plaster, sand, and metal, and use a variety of tools and equipment to create and repair molds.

1. Create and repair plaster molds

Machine Castings Plasterers create and repair plaster molds used in the production of metal castings. They use a variety of materials, including plaster, sand, and metal, and use a variety of tools and equipment to create and repair molds.

- Follow blueprints and specifications to create new molds.

- Inspect molds for defects and repair any damage.

- Clean and prepare molds for use.

2. Operate casting machines

Machine Castings Plasterers operate casting machines to produce metal castings. They set up the machines, load the molds, and monitor the casting process.

- Set up casting machines according to specifications.

- Load molds into casting machines.

- Monitor casting process to ensure quality.

3. Inspect castings

Machine Castings Plasterers inspect castings for defects. They use a variety of tools and equipment to inspect castings, and they identify any defects that need to be repaired.

- Inspect castings for defects.

- Identify and mark defects.

- Repair defects or reject castings.

4. Maintain equipment

Machine Castings Plasterers maintain equipment used in the casting process. They clean and lubricate equipment, and they make minor repairs as needed.

- Clean and lubricate equipment.

- Make minor repairs to equipment.

- Report major repairs to supervisors.

Interview Tips

Preparing for an interview for a Machine Castings Plasterer position can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Practice your answers with a friend or family member.

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview shows that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

- Ask questions about the company’s culture and values.

- Ask questions about the specific requirements of the position.

- Ask questions about the interviewer’s experience with the company.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you are respectful of their time.

- Wear a suit or business casual attire.

- Be clean and well-groomed.

- Arrive on time for your interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Castings Plasterer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.