Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Cementer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Cementer so you can tailor your answers to impress potential employers.

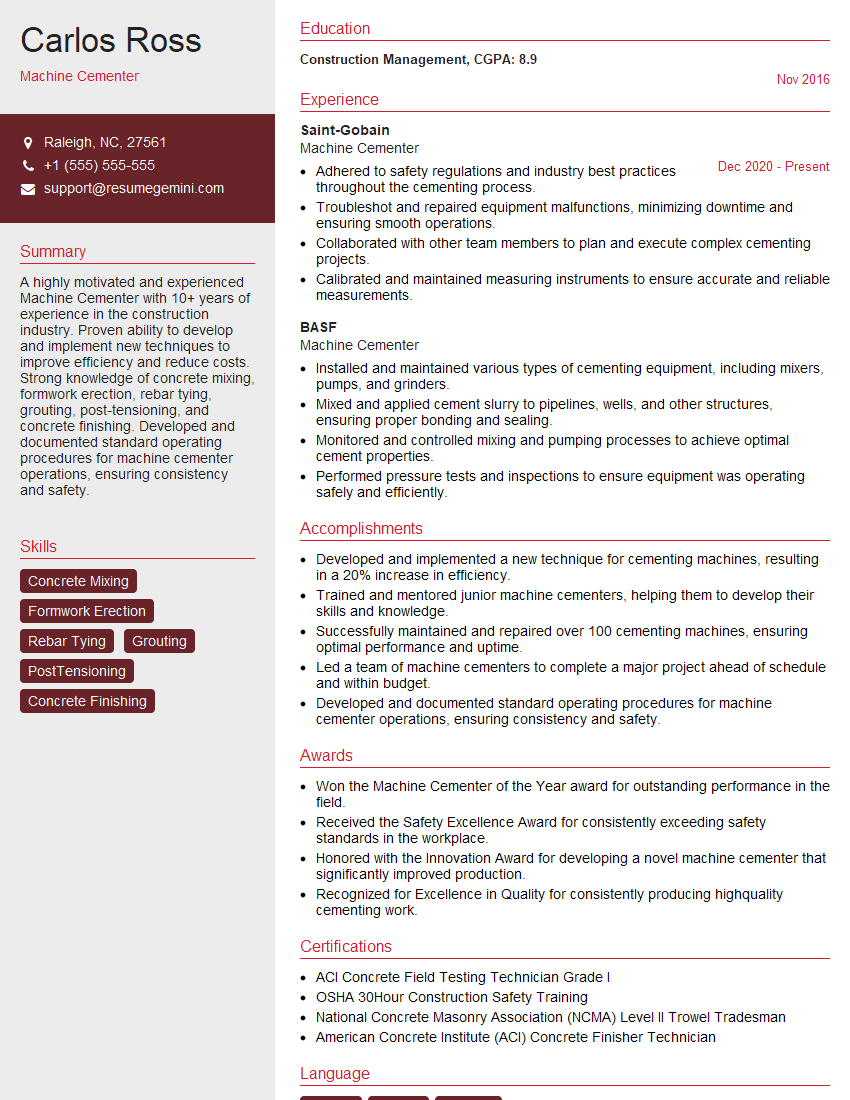

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Cementer

1. What are your responsibilities as a Machine Cementer?

As a Machine Cementer, my primary responsibilities include:

- Installing and maintaining cementing equipment, such as cement pumps, mixers, and lines.

- Preparing and mixing cement slurries according to specifications.

- Pumping cement slurries into wells to seal casings and prevent fluid migration.

- Monitoring cementing operations and ensuring proper placement and setting of the cement.

- Troubleshooting and resolving any problems that may arise during cementing operations.

2. Describe the different types of cementing operations you have performed.

Primary Cementing

- Installing and cementing casing strings to seal the wellbore and prevent fluid migration.

- Ensuring proper zonal isolation and protecting the reservoir from contamination.

Liner Cementing

- Cementing liners within existing casings to enhance wellbore stability or isolate different reservoir zones.

- Maintaining fluid communication between zones while preventing cross-contamination.

Squeeze Cementing

- Pumping cement into fractures or damaged sections of the wellbore to regain well control or prevent fluid loss.

- Restoring zonal isolation and ensuring the integrity of the well.

3. How do you ensure the quality of the cement slurry?

To ensure the quality of the cement slurry, I follow these steps:

- Selecting appropriate cement types and additives based on well conditions and requirements.

- Accurately measuring and mixing the cement components to achieve the desired properties.

- Conducting quality control tests, such as density and viscosity measurements, to verify slurry quality.

- Making adjustments to the slurry design as necessary to meet specifications and performance requirements.

4. What are the safety precautions you take during cementing operations?

Safety is paramount during cementing operations, and I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including gloves, respirators, and protective suits.

- Following established procedures and guidelines to minimize risks and prevent accidents.

- Inspecting equipment regularly to ensure its proper function and safety.

- Being aware of potential hazards, such as high pressure and hazardous chemicals, and taking measures to mitigate them.

- Communicating clearly with team members and coordinating operations effectively to maintain a safe work environment.

5. How do you troubleshoot and resolve problems that may arise during cementing operations?

When troubleshooting and resolving problems during cementing operations, I follow these steps:

- Identifying the problem accurately by analyzing symptoms, monitoring gauges, and reviewing data.

- Consulting with engineers and other team members for their insights and expertise.

- Investigating potential causes and developing appropriate solutions.

- Implementing corrective measures, such as adjusting slurry properties, rerouting lines, or replacing equipment.

- Monitoring the situation closely to ensure that the problem has been resolved effectively.

6. How do you stay up-to-date with the latest advancements in cementing technology?

To keep up with the latest advancements in cementing technology, I pursue the following strategies:

- Attending industry conferences, seminars, and workshops.

- Reading technical articles, journals, and industry publications.

- Participating in professional organizations and networking with other cementing professionals.

- Staying informed about new products, equipment, and techniques through manufacturers’ updates and training sessions.

- Consulting with experts and seeking advice on innovative approaches to cementing operations.

7. How do you work effectively as part of a team in a fast-paced environment?

In a fast-paced team environment, I contribute effectively by:

- Communicating clearly and concisely to ensure everyone is informed and on the same page.

- Sharing knowledge and expertise with team members to support their growth and development.

- Supporting others when they need assistance and stepping up to take on additional responsibilities.

- Maintaining a positive attitude and fostering a collaborative work atmosphere.

- Adapting quickly to changing priorities and working efficiently under pressure to meet deadlines.

8. Describe a challenging cementing operation you have encountered and how you overcame it.

In a recent project, we encountered a challenging cementing operation due to a narrow drilling window and limited clearance in the wellbore. To overcome this, I worked closely with engineers to design a custom slurry with specific properties to ensure proper placement. I also collaborated with the drilling team to optimize the hole cleaning process and minimize the risk of differential sticking. By carefully planning and executing the operation, we successfully cemented the well and achieved zonal isolation without any complications.

9. How do you handle working in remote or offshore locations?

Working in remote or offshore locations requires adaptability and resourcefulness. I am comfortable working in isolated environments and have experience with offshore rig operations. I am proficient in managing logistics, ensuring equipment functionality, and maintaining a safe work environment. I am also familiar with the challenges of working in extreme weather conditions and have developed strategies to mitigate risks and maintain efficiency.

10. What are your goals for professional development in the field of cementing?

I am eager to expand my knowledge and expertise in cementing. I plan to continue attending industry events and pursuing certifications to stay updated with the latest advancements. I am particularly interested in exploring new technologies, such as foam cementing and lightweight cement systems, to enhance cementing operations. I am also keen on developing my leadership skills to mentor and guide junior cementing professionals in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Cementer is responsible for performing a variety of tasks related to the manufacture of concrete products. Their primary duty is to operate and maintain various machines used in the cementing process, ensuring efficient production and high-quality products.

1. Machine Operation and Maintenance

Operate cementing machines such as mixers, conveyors, and curing chambers, ensuring efficient and smooth production.

- Monitor and adjust machine settings, such as temperature, speed, and pressure.

- Perform routine maintenance and repairs on equipment, including lubrication, cleaning, and troubleshooting.

2. Material Handling

Handle and mix various materials, including cement, aggregates, and additives, to create concrete mixes.

- Weigh and measure materials accurately, following specified recipes and quality standards.

- Ensure the proper storage and handling of materials to prevent contamination or deterioration.

3. Quality Control

Monitor the production process and ensure that the final products meet quality specifications.

- Perform visual inspections of products, checking for defects, cracks, or other irregularities.

- Take samples for testing and record quality control data to ensure compliance with standards.

4. Safety Compliance

Follow all safety protocols and regulations related to the operation of machinery and handling of hazardous materials.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators.

- Maintain a clean and safe work environment, reporting any potential hazards or risks.

Interview Tips

Interviewing for a Machine Cementer role requires preparation and knowledge of the industry. Here are some tips to help you ace the interview:

1. Research the Company

Learn about the company’s history, values, and the specific industry they operate in. This shows that you’re interested in the opportunity and have taken the time to understand their business.

- Review the company’s website, social media pages, and any recent news articles or press releases.

- Identify any areas where you can align your skills and experience with the company’s needs.

2. Practice Your Answers

Prepare for common interview questions related to your experience and qualifications. Practice answering them clearly and concisely, using specific examples to demonstrate your skills.

- Review job descriptions and identify the key responsibilities and requirements.

- Think of specific examples from your previous work experience that highlight your abilities.

3. Highlight Your Safety Knowledge

Emphasize your understanding of safety protocols and regulations in the manufacturing industry. This is a crucial aspect of the role, and employers will want to ensure that you are committed to maintaining a safe work environment.

- Describe your experience with handling hazardous materials, using PPE, and preventing accidents.

- Share your knowledge of industry-specific safety standards and regulations.

4. Showcase Your Attention to Quality

Machine Cementers play a vital role in ensuring the quality of concrete products. Highlight your attention to detail, your commitment to meeting quality standards, and your experience with quality control processes.

- Provide examples of how you have identified and resolved quality issues in previous roles.

- Explain your understanding of quality control procedures and your ability to maintain accurate records.

5. Be Enthusiastic and Show Passion

Let the interviewer know that you are genuinely interested in the position and the industry. Show your enthusiasm for working in a manufacturing environment and your passion for producing high-quality products.

- Express your eagerness to learn and grow within the company.

- Convey your belief in the importance of manufacturing and your commitment to excellence.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Cementer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.