Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

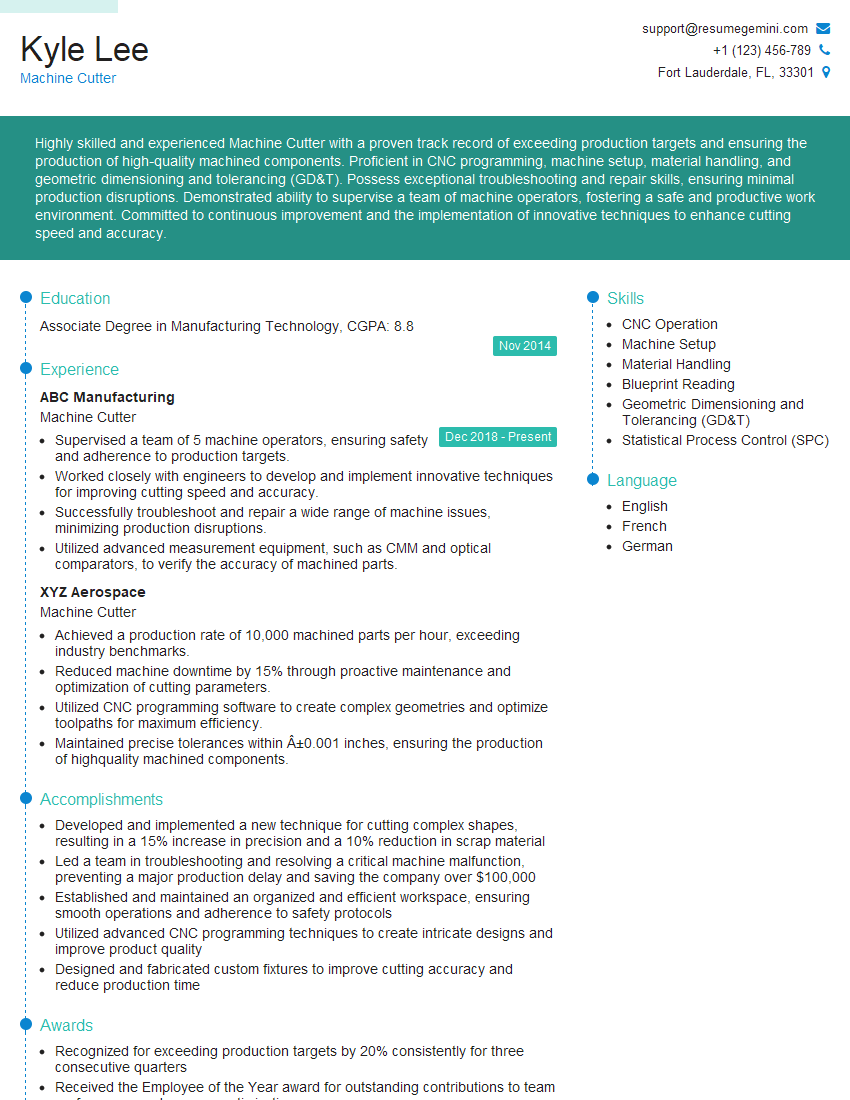

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Cutter

1. How do you ensure the accuracy and precision of your cutting operations?

To ensure the accuracy and precision of my cutting operations, I follow a rigorous process that includes:

- Using high-quality cutting tools that are regularly calibrated and maintained.

- Employing precise measuring and alignment techniques to ensure that the cuts are made to the exact specifications.

- Conducting regular inspections and quality control checks to verify the accuracy of the cuts.

- Adhering to established cutting procedures and best practices.

- Continuously improving my skills and knowledge to stay updated with the latest cutting techniques and technologies.

2. What are the different types of cutting operations you are proficient in?

I am proficient in a wide range of cutting operations, including:

- Straight cutting

- Contour cutting

- Bevel cutting

- Plasma cutting

- Waterjet cutting

- Laser cutting

- Oxy-fuel cutting

- CNC cutting

3. How do you handle complex cutting projects that require multiple cuts and precise alignment?

For complex cutting projects, I meticulously plan and execute each step to ensure accuracy and precision:

- Review the project specifications thoroughly to understand the requirements.

- Break down the project into smaller, manageable tasks.

- Use jigs and fixtures to ensure precise alignment and repeatability.

- Program the cutting machine with the appropriate parameters.

- Conduct trial cuts to verify the accuracy before proceeding with the actual cuts.

- Monitor the cutting process closely and make adjustments as needed.

- Inspect the finished product thoroughly to ensure it meets the specifications.

4. How do you stay updated with the latest cutting techniques and advancements?

To stay informed about the latest cutting techniques and advancements, I:

- Attend industry conferences, workshops, and training programs.

- Read trade publications and technical journals.

- Network with other machinists and industry professionals.

- Experiment with new techniques and technologies in my own work.

- Seek feedback from colleagues and supervisors to continuously improve my skills.

5. How do you handle tight deadlines and ensure timely delivery of cut parts?

To meet tight deadlines, I prioritize tasks, optimize my workflow, and communicate effectively:

- Plan the cutting process carefully to minimize downtime and maximize efficiency.

- Use automation and technology to streamline the cutting operations.

- Work extended hours if necessary to meet the deadline.

- Communicate regularly with clients to keep them informed of progress and any potential delays.

- Explore alternative cutting methods or suppliers to expedite the process if required.

6. How do you ensure the safety of yourself and others while operating cutting machines?

Safety is paramount in my work, and I adhere to the following practices:

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing.

- Follow established safety protocols and procedures.

- Inspect cutting equipment regularly for any defects or hazards.

- Maintain a clean and organized work area to prevent tripping or other accidents.

- Never operate cutting machines under the influence of drugs or alcohol.

- Stay alert and focused while operating cutting machines.

7. Describe a situation where you encountered a problem with a cutting machine and how you resolved it.

In one instance, I encountered a problem with a CNC cutting machine that resulted in inaccurate cuts:

- I first checked the cutting parameters to ensure they were correct.

- Next, I inspected the cutting tool for any damage or wear.

- I then recalibrated the machine and performed a test cut.

- After identifying the cause as a faulty sensor, I replaced it with a new one.

- Finally, I re-calibrated the machine and the cuts were back to the required accuracy.

8. How do you continuously improve your cutting skills and knowledge?

I believe in continuous improvement, and I take the following steps to enhance my skills and knowledge:

- Seek feedback from colleagues, supervisors, and clients to identify areas for improvement.

- Take advantage of training opportunities to learn new techniques and technologies.

- Experiment with different cutting parameters and materials to expand my capabilities.

- Stay up-to-date with industry best practices and advancements.

- Share my knowledge and experience with others to contribute to the field.

9. Why are you interested in working as a Machine Cutter for our company?

I am eager to join your company as a Machine Cutter because:

- I am impressed by your company’s reputation for producing high-quality products.

- I believe my skills and experience would be a valuable asset to your team.

- I am passionate about precision cutting and delivering exceptional results.

- I am excited about the opportunity to contribute to the success of your company.

- I am confident that I can make a positive impact in this role.

10. What sets you apart from other candidates for this position?

I believe several factors set me apart from other candidates for this position:

- My extensive experience in various cutting operations, including complex and demanding projects.

- My commitment to accuracy and precision, ensuring that every cut meets the highest standards.

- My ability to troubleshoot and resolve problems quickly and efficiently, minimizing downtime.

- My passion for continuous learning and staying updated with the latest cutting techniques and technologies.

- My strong work ethic, dedication to safety, and collaborative nature.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Cutters are responsible for operating and maintaining cutting machines used in the production of various materials. They ensure that machines are operating correctly, producing high-quality cuts, and meeting production targets.

1. Machine Operation

Operate cutting machines to cut various materials, such as metal, plastic, wood, and glass.

- Set up and adjust cutting machines according to specifications.

- Monitor machine operation and make necessary adjustments to maintain precision cuts.

2. Maintenance and Repair

Perform routine maintenance on cutting machines to ensure optimal performance.

- Lubricate and inspect machines regularly.

- Identify and resolve minor machine malfunctions.

3. Quality Control

Inspect cut materials for quality and accuracy.

- Measure and verify cut dimensions using measuring tools.

- Identify and correct any deviations from specifications.

4. Production Optimization

Monitor production processes and identify areas for improvement.

- Suggest modifications to cutting techniques or machine settings to enhance efficiency.

- Participate in production planning and scheduling to meet customer requirements.

Interview Tips

Preparing thoroughly for a Machine Cutter interview can significantly increase your chances of success. Here are some tips to help you ace it:

1. Research the Company and Position

Before the interview, thoroughly research the company’s history, values, and the specific role you are applying for. This will demonstrate your interest and enthusiasm.

- Visit the company’s website and social media pages.

- Read industry news and articles related to the company and the machine cutting industry.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by rehearsing your answers in advance.

- Why are you interested in this role at our company?

- Tell me about your experience with machine cutting.

- How do you handle working in a fast-paced environment?

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements.

- Quantify your accomplishments using specific numbers and metrics.

- Provide examples of your ability to solve problems, work independently, and contribute to a team.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- What are the company’s current production goals?

- How is the company investing in machine cutting technology?

- What are the opportunities for career growth within the company?

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving for the interview on time.

- Wear business attire that is clean and pressed.

- Be punctual and allow yourself ample time to find the interview location.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!