Are you gearing up for an interview for a Machine Deburrer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Deburrer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

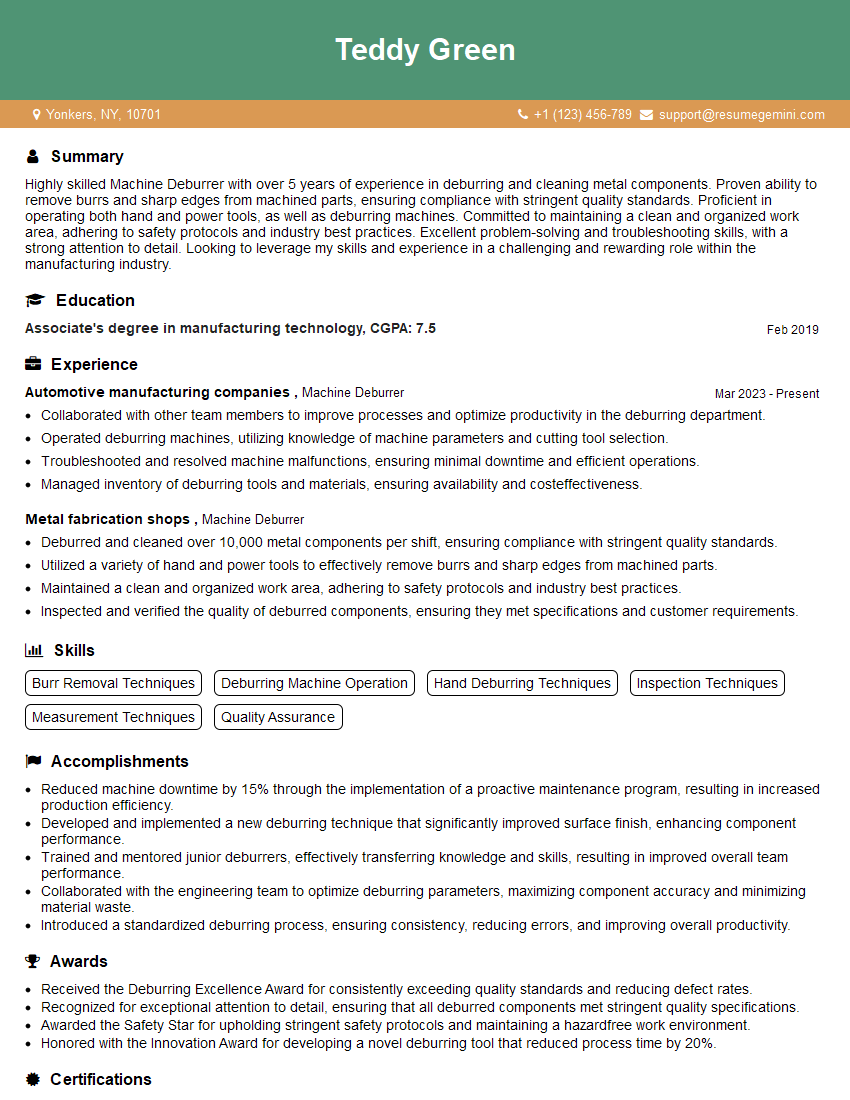

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Deburrer

1. What is the difference between manual and automatic deburring machines?

Machine deburring is a process of removing burrs from metal parts. There are two main types of deburring machines: manual and automatic. Manual deburring machines are operated by hand, while automatic deburring machines are operated by a computer. Automatic deburring machines are more efficient and accurate than manual deburring machines, but they are also more expensive.

2. What are the different types of deburring tools?

There are a variety of deburring tools available, each with its own unique advantages and disadvantages. Some of the most common types of deburring tools include:

- Burr bits

- Hand files

- Rotary burrs

- Sanding belts

- Wire brushes

3. What are the safety precautions that should be taken when operating a deburring machine?

Deburring machines can be dangerous if they are not operated properly. It is important to follow all of the safety precautions that are outlined in the machine’s operating manual. Some of the most important safety precautions include:

- Wearing proper safety gear, including eye protection, gloves, and a dust mask

- Keeping the machine clean and free of debris

- Never operating the machine when it is not properly grounded

- Being aware of the machine’s surroundings and keeping clear of moving parts

4. What are the different types of materials that can be deburred?

Deburring machines can be used to deburr a variety of materials, including:

- Metal

- Plastic

- Wood

- Composite materials

5. What are the different applications for deburring machines?

Deburring machines are used in a variety of applications, including:

- Removing burrs from metal parts

- Cleaning up edges of plastic parts

- Smoothing out the surfaces of wood products

- Deburring composite materials

6. What are the different factors to consider when selecting a deburring machine?

When selecting a deburring machine, it is important to consider a number of factors, including:

- The type of material that will be deburred

- The size and shape of the parts that will be deburred

- The desired level of precision

- The budget

7. How do you troubleshoot a deburring machine that is not working properly?

If a deburring machine is not working properly, there are a number of things that can be done to troubleshoot the problem. Some of the most common troubleshooting steps include:

- Checking the power supply

- Inspecting the machine for any loose or damaged parts

- Cleaning the machine

- Calibrating the machine

8. What are the maintenance requirements for a deburring machine?

Deburring machines require regular maintenance to keep them operating properly. Some of the most common maintenance tasks include:

- Cleaning the machine

- Lubricating the moving parts

- Inspecting the machine for any loose or damaged parts

- Calibrating the machine

9. What are the safety features of a deburring machine?

Deburring machines are equipped with a number of safety features to protect the operator. Some of the most common safety features include:

- A guarded cutting head

- An emergency stop button

- A dust collection system

- A noise reduction system

10. What are the benefits of using a deburring machine?

There are a number of benefits to using a deburring machine, including:

- Increased efficiency

- Improved accuracy

- Reduced costs

- Improved safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Deburrer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Deburrer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Deburrer is responsible for removing burrs, sharp edges, or other imperfections from machined parts using specialized equipment and tools. This involves meticulous attention to detail and a thorough understanding of the manufacturing process.

1. Deburring Operations

The primary responsibility is to perform deburring operations on various materials, including metal, plastic, and composites

- Use manual or automated deburring tools and machines to remove burrs and sharp edges

- Select the appropriate deburring technique and tools based on the material and geometry of the part

2. Quality Control

Ensure that deburred parts meet the specified quality standards and tolerances

- Inspect parts for burrs and other defects using visual and tactile methods

- Identify and report any non-conformances to the supervisor or quality control department

3. Machine Setup and Maintenance

Set up and operate deburring machines efficiently to optimize productivity and minimize downtime

- Inspect and maintain deburring equipment to ensure optimal performance

- Calibrate and adjust machines according to specifications

4. Safety Compliance

Adhere to all safety protocols and regulations related to deburring operations

- Wear appropriate personal protective equipment (PPE)

- Follow established safety procedures and lockout/tagout protocols

Interview Preparation Tips

To ace the interview for a Machine Deburrer position, it is crucial to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Role

Gather information about the company’s industry, products, and the specific role you are applying for. Understanding the company’s values and goals will enable you to tailor your answers and demonstrate your alignment with their needs.

- Visit the company website and LinkedIn page

- Read industry publications and news articles

2. Highlight Relevant Skills and Experience

Emphasize your experience in deburring operations, machine setup and maintenance, and quality control. Quantify your accomplishments whenever possible to showcase your impact.

- Describe specific projects where you successfully removed burrs and sharp edges from complex parts

- Provide examples of how you improved efficiency or reduced defects through your deburring techniques

3. Demonstrate Safety Awareness

Safety is paramount in deburring operations. Highlight your knowledge of safety protocols and your commitment to adhering to them. Explain how you prioritize safety in your work environment.

- Discuss your experience with PPE and lockout/tagout procedures

- Share examples of how you have identified and mitigated potential safety hazards

4. Prepare for Common Interview Questions

Practice answering common interview questions to build confidence and structure your responses effectively. Consider questions related to your deburring experience, attention to detail, and problem-solving abilities.

- Tell me about your experience in deburring different types of materials

- Describe a time when you had to meet a tight deadline for a deburring project

- How do you handle working with sharp tools and machinery?

Next Step:

Now that you’re armed with the knowledge of Machine Deburrer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Deburrer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini