Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Dyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

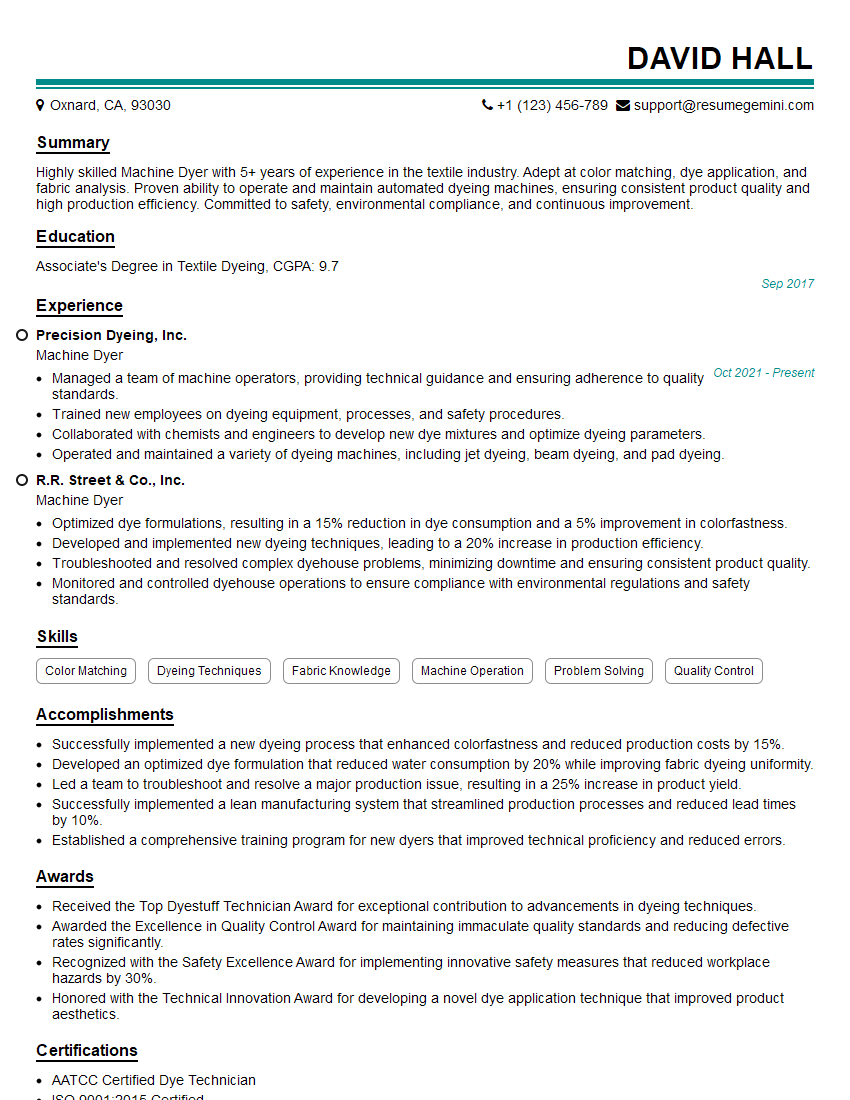

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Dyer

1. How do you determine the correct dye concentration for a given fabric and dye type?

To determine the correct dye concentration, I consider the following factors:

- Fabric type: Different fabrics have varying affinities for dyes, so I adjust the concentration accordingly.

- Dye type: Different dyes have different strengths and require different concentrations.

- Desired shade: The desired shade of the fabric influences the concentration required.

- Dyeing method: The specific dyeing method used (e.g., batch, continuous, exhaust) can affect the optimal concentration.

2. Describe the steps involved in the dyeing process and explain the role of each step.

Fabric Preparation

- Scouring: Removes impurities and prepares the fabric for dyeing.

- Bleaching: Whitens the fabric and removes any existing color.

Dyeing

- Dye application: The dye is applied to the fabric using a specific method (e.g., batch, continuous).

- Dye fixation: Chemical or heat treatments are used to bond the dye to the fabric.

Post-Dyeing

- Washing: Removes excess dye and chemicals.

- Drying: Dries the fabric to prepare it for further processing.

3. How do you handle shade variations in the dyeing process?

To handle shade variations, I employ the following techniques:

- Color matching: Using spectrophotometers to match the target shade accurately.

- Adjustment of dye concentration: Fine-tuning the dye concentration based on shade variations.

- Control of dyeing parameters: Monitoring and adjusting temperature, pH, and time to ensure consistent results.

- Lab dips: Creating small-scale samples to test dye formulations and avoid large-scale production issues.

4. What are the common defects associated with dyeing and how do you prevent them?

Common dyeing defects and their prevention methods include:

- Uneven dyeing: Ensuring proper fabric preparation, dye application, and dye fixation.

- Color bleeding: Using color-fast dyes, optimizing dyeing parameters, and post-dyeing treatments.

- Migration: Separating fabrics with different dye affinities before dyeing and using migration inhibitors.

- Crocking: Applying appropriate mordants and optimizing post-dyeing treatments.

- Tendering: Avoiding harsh chemicals and excessive exposure to high temperatures during dyeing.

5. How do you ensure the quality of dyed fabrics?

To ensure quality, I implement the following practices:

- Color matching: Verifying shades against standards using spectrophotometers.

- Fastness testing: Performing tests to assess colorfastness against washing, light, and rubbing.

- Inspection: Conducting visual inspections to identify any defects or variations.

- Process control: Monitoring and recording dyeing parameters to ensure consistency.

- Traceability: Maintaining records of dyes, fabrics, and dyeing conditions for quality assurance.

6. What are the latest advancements in dyeing technology that you are aware of?

- Digital printing: Precise application of dyes using inkjet technology for intricate designs.

- Sustainable dyeing: Environmentally friendly dyes and processes that minimize water and energy consumption.

- Nanotechnology: Using nanoparticles to enhance dye penetration and fastness.

- Automation: Automated dyeing machines for increased efficiency and consistency.

- Optical brightening: Advanced optical brightening agents to enhance fabric whiteness and vibrancy.

7. How do you stay up-to-date with the latest industry trends and best practices in dyeing?

- Industry conferences: Attending industry events to learn about new technologies and techniques.

- Trade journals: Subscribing to industry publications for the latest research and developments.

- Online courses and webinars: Taking online courses and participating in webinars to expand my knowledge.

- Networking: Connecting with other professionals in the field to share knowledge and experience.

- Collaboration with suppliers: Working with dye suppliers to learn about new products and innovative applications.

8. Describe the role of mordants in the dyeing process.

- Enhance dye affinity: Mordants bind to both the fabric and the dye, improving dye uptake and colorfastness.

- Alter shades: Different mordants can modify the shade of the dyed fabric.

- Improve washfastness: Mordants help to prevent dye bleeding during washing.

- Types of mordants: Common mordants include alum, tannin, and copper sulfate.

9. How do you troubleshoot common dyeing problems, such as color bleeding or uneven dyeing?

To troubleshoot common dyeing problems:

- Color bleeding: Identify the cause (e.g., poor dye fixation, low colorfastness dyes), and adjust dyeing parameters or use appropriate mordants.

- Uneven dyeing: Check fabric preparation, dye application equipment, and dyeing conditions. Optimize parameters to ensure even dye distribution.

- Other problems: Based on the nature of the problem, analyze the dyeing process, test the fabric and dye, and make necessary adjustments.

10. How do you ensure that dyed fabrics meet customer specifications?

- Clear communication: Understand customer requirements and specifications through thorough discussions.

- Sample approval: Obtain customer approval on color, shade, and other quality aspects before large-scale production.

- Quality control: Implement rigorous quality control measures throughout the dyeing process, including color matching, fastness testing, and visual inspection.

- Traceability: Maintain accurate records of dyeing parameters, fabrics, and dyes used to facilitate quality assurance and traceability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Dyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Dyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Dyers are responsible for dyeing textiles and other materials using a variety of machines. They must have a strong understanding of the dyeing process, as well as the different types of dyes and chemicals used. Machine Dyers must also be able to operate and maintain the dyeing machines, and ensure that the dyed materials meet the required specifications.

1. Dyeing Textiles and Other Materials

Machine Dyers are responsible for dyeing a wide variety of textiles and other materials, including fabrics, yarns, and carpets. They must be able to determine the correct dye type and concentration for each material, and ensure that the dyeing process is carried out correctly.

- Select the correct dye type and concentration for each material.

- Load the dyeing machine with the textiles or other materials.

- Start the dyeing process and monitor the temperature and pH of the dye bath.

- Unload the dyed materials and inspect them for quality.

2. Operating and Maintaining Dyeing Machines

Machine Dyers must be able to operate and maintain a variety of dyeing machines, including batch dyeing machines, continuous dyeing machines, and jet dyeing machines. They must be able to troubleshoot any problems that occur with the machines, and ensure that they are operating safely and efficiently.

- Operate a variety of dyeing machines, including batch dyeing machines, continuous dyeing machines, and jet dyeing machines.

- Troubleshoot any problems that occur with the dyeing machines.

- Perform regular maintenance on the dyeing machines, including cleaning and lubrication.

3. Ensuring Quality Control

Machine Dyers must ensure that the dyed materials meet the required specifications. They must be able to inspect the dyed materials for defects, such as uneven dyeing, streaks, or color fading. They must also be able to take corrective action if any defects are found.

- Inspect the dyed materials for defects, such as uneven dyeing, streaks, or color fading.

- Take corrective action if any defects are found.

- Maintain quality control records.

4. Safety and Environmental Compliance

Machine Dyers must be aware of the safety and environmental regulations that apply to their work. They must be able to follow these regulations, and ensure that the dyeing process is carried out in a safe and environmentally responsible manner.

- Follow all safety and environmental regulations.

- Wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- Dispose of waste dyes and chemicals properly.

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your next Machine Dyer interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member on your answers.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Machine Dyer. Be prepared to talk about your skills and knowledge, and to provide examples of your work. You can also highlight any relevant experience you have in other areas, such as quality control or safety.

- Make a list of your skills and knowledge.

- Think about specific examples of your work that you can share.

- Be prepared to talk about your experience in other areas, such as quality control or safety.

4. Dress Professionally and Be on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose appropriate business attire.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

5. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and to be enthusiastic about the position. The interviewer wants to get to know you and to see if you are a good fit for the company. Be honest and open, and let your personality shine through.

- Be yourself.

- Be enthusiastic about the position.

- Be honest and open.

- Let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Dyer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.