Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Etcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

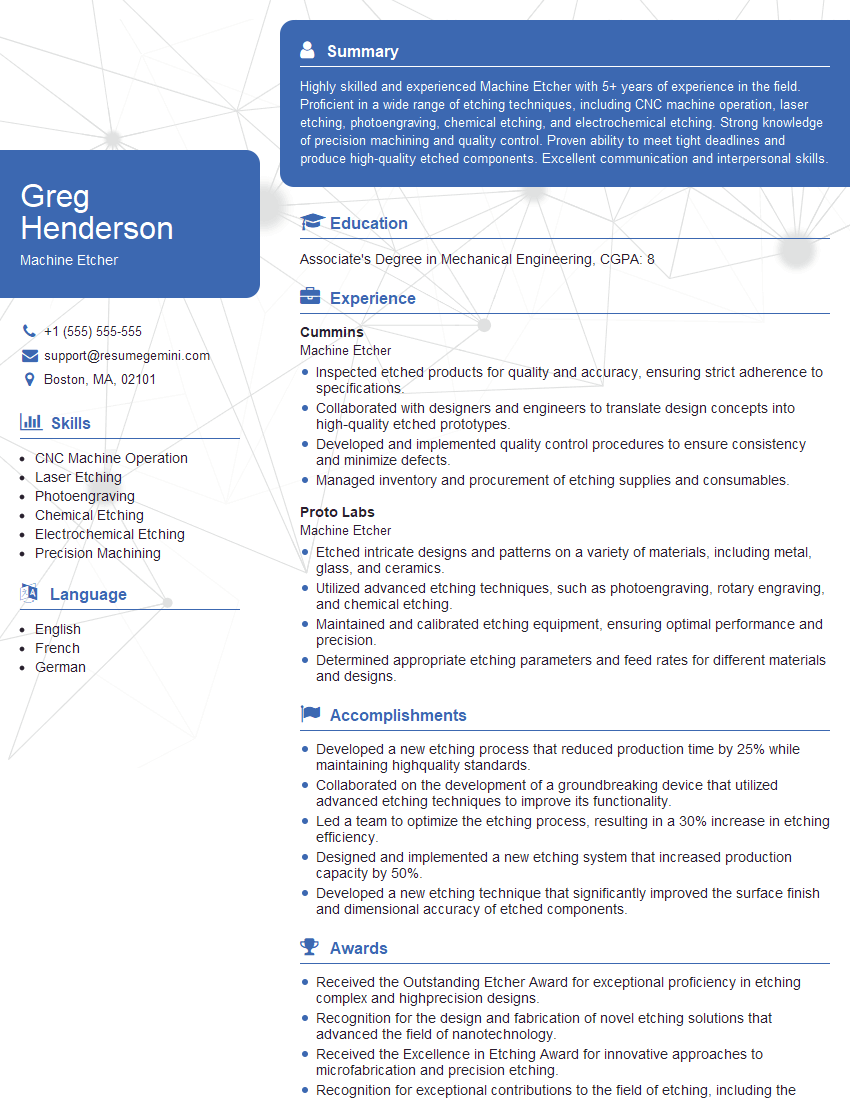

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Etcher

1. Describe the different types of etching machines and their applications?

There are various types of etching machines, each with unique applications:

- Wet Chemical Etching: Uses liquid etchants for high-precision etching with isotropic profiles.

- Dry Etching: Employs plasma or reactive gases for anisotropic etching with higher aspect ratios.

- Reactive Ion Etching (RIE): Combines dry etching with ion bombardment for precise etching of layered materials.

- Deep Reactive Ion Etching (DRIE): Extends RIE for deep narrow etching of high-aspect-ratio structures.

- Inductively Coupled Plasma (ICP) Etching: Utilizes a separate plasma source to generate ions for high-density etching.

2. What are the key parameters to consider when setting up an etching process?

Etching Rate:

- Determined by factors such as etchant concentration, temperature, and agitation.

- Critical for achieving desired etch depth and selectivity.

Selectivity:

- Measured by the ratio of etch rates between target and mask materials.

- Ensures minimal damage to non-target areas.

Uniformity:

- Refers to the consistency of etching across the substrate.

- Affected by factors such as etch time, etchant flow, and substrate agitation.

Surface Roughness:

- Describes the smoothness of the etched surface.

- Influenced by etch parameters and substrate material composition.

3. How do you troubleshoot common etching problems, such as under-etching or over-etching?

Troubleshooting etching problems requires a systematic approach:

- Under-etching:

- Check etchant concentration, temperature, and agitation.

- Verify mask integrity and exposure parameters.

- Consider using a more aggressive etchant or longer etch time.

- Over-etching:

- Reduce etchant concentration, temperature, or etch time.

- Ensure proper mask protection and over-etch allowance.

- Consider using a more selective etchant.

4. What are the safety precautions and best practices for handling hazardous chemicals used in etching?

Handling hazardous chemicals requires strict adherence to safety protocols:

- Wear appropriate personal protective equipment (PPE) including gloves, goggles, and respiratory mask.

- Work in a well-ventilated area with proper exhaust systems.

- Store chemicals in designated areas and follow proper disposal procedures.

- Understand the Material Safety Data Sheets (MSDSs) for all chemicals used.

- Receive proper training and be aware of emergency response protocols.

5. Explain the role of photoresists in etching processes and describe different types of photoresists.

Photoresists play a crucial role in etching by:

- Creating a protective layer on the substrate.

- Defining the areas to be etched through selective exposure to light.

Types of photoresists include:

- Positive Photoresist: Becomes soluble in developer after exposure to light.

- Negative Photoresist: Becomes insoluble in developer after exposure to light.

- Thick Photoresist: Used for thick film etching with high aspect ratios.

- High-Resolution Photoresist: Provides high-precision patterns for fine-feature etching.

6. Describe the basic principles of isotropic and anisotropic etching.

Etching can be isotropic or anisotropic based on the direction of etching:

- Isotropic Etching: Etches in all directions at the same rate, resulting in isotropic profiles.

- Anisotropic Etching: Etches preferentially in certain directions, creating anisotropic profiles with well-defined sidewalls.

The choice of etching process depends on the desired pattern and substrate material properties.

7. Explain the difference between wet and dry etching techniques.

Wet and dry etching techniques have distinct advantages and disadvantages:

- Wet Etching:

- Uses liquid etchants for isotropic etching.

- Provides high selectivity and low cost.

- Can be limited by under-etching and corrosion.

- Dry Etching:

- Uses plasma or reactive gases for anisotropic etching.

- Offers higher precision and control.

- Can be expensive and requires specialized equipment.

8. Discuss the importance of etch stop layers in etching processes.

Etch stop layers play a critical role in etching:

- Prevent over-etching by stopping the etch process at a specific depth.

- Provide high selectivity between the target layer and the stop layer.

- Enable the creation of complex structures and patterns.

Common etch stop layers include silicon nitride, silicon oxide, and metal films.

9. Explain the concept of aspect ratio in etching and how it affects the etching process.

Aspect ratio refers to the ratio of etch depth to pattern width:

- High Aspect Ratio (HAR): Etch depth is significantly greater than pattern width.

- Low Aspect Ratio (LAR): Etch depth is comparable to pattern width.

HAR etching requires specialized techniques and careful process control to maintain vertical sidewalls and prevent under-etching.

10. Describe the challenges in etching 3D structures and how they can be overcome.

Etching 3D structures presents several challenges:

- Non-uniform Etching: Different etch rates in different directions can lead to non-uniformities.

- Shadowing Effects: Tall structures can block etchant from reaching lower areas.

- Under-etching: Etchant can undercut the sidewalls of 3D structures.

To overcome these challenges, techniques such as directional etching, sacrificial layers, and conformal etching can be employed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Etcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Etcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Etchers are responsible for operating etching machines to create intricate designs on a variety of surfaces, including metal, glass, and plastic. They use a variety of techniques, including chemical etching, laser etching, and sandblasting, to achieve the desired results.

1. Machine Operation

Operate etching machines to create designs on a variety of surfaces.

- Follow instructions and blueprints to set up and operate machines.

- Monitor machines during operation to ensure they are functioning properly.

2. Design Creation

Create designs for etching using software and tools.

- Use computer-aided design (CAD) software to create designs.

- Work with customers to develop and refine designs.

3. Etching Techniques

Use a variety of etching techniques to create designs.

- Use chemical etching to create designs by exposing the surface to a chemical solution.

- Use laser etching to create designs by using a laser to vaporize the surface.

- Use sandblasting to create designs by using a stream of abrasive particles to erode the surface.

4. Quality Control

Inspect etched products to ensure they meet quality standards.

- Inspect products for defects and imperfections.

- Make adjustments to machines and techniques to improve quality.

Interview Tips

Preparing for a Machine Etcher interview can help you present yourself as a knowledgeable and qualified candidate. Here are some tips to help you ace the interview:

1. Research the Company

Before the interview, take some time to research the company and learn about their products, services, and culture. This will help you understand the company’s needs and how your skills and experience can contribute to their success.

- Visit the company’s website.

- Read articles about the company in industry publications.

- Talk to people who work at the company.

2. Practice Your Answers

Once you have researched the company, take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your strengths and weaknesses.

- Prepare answers to questions about your experience and skills.

- Be prepared to talk about your motivation for applying for the job.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for the interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure your shoes are clean and polished.

- Choose clothes that are clean, pressed, and fit well.

- Avoid wearing clothes that are too revealing or too casual.

- Make sure your shoes are clean and polished.

4. Be Punctual

Punctuality is important, so make sure you arrive for the interview on time. If you are running late, be sure to call the interviewer and let them know.

- Plan your route to the interview in advance.

- Leave early to allow for unexpected delays.

- If you are running late, call the interviewer and let them know.

Next Step:

Now that you’re armed with the knowledge of Machine Etcher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Etcher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini