Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Featheredger and Reducer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

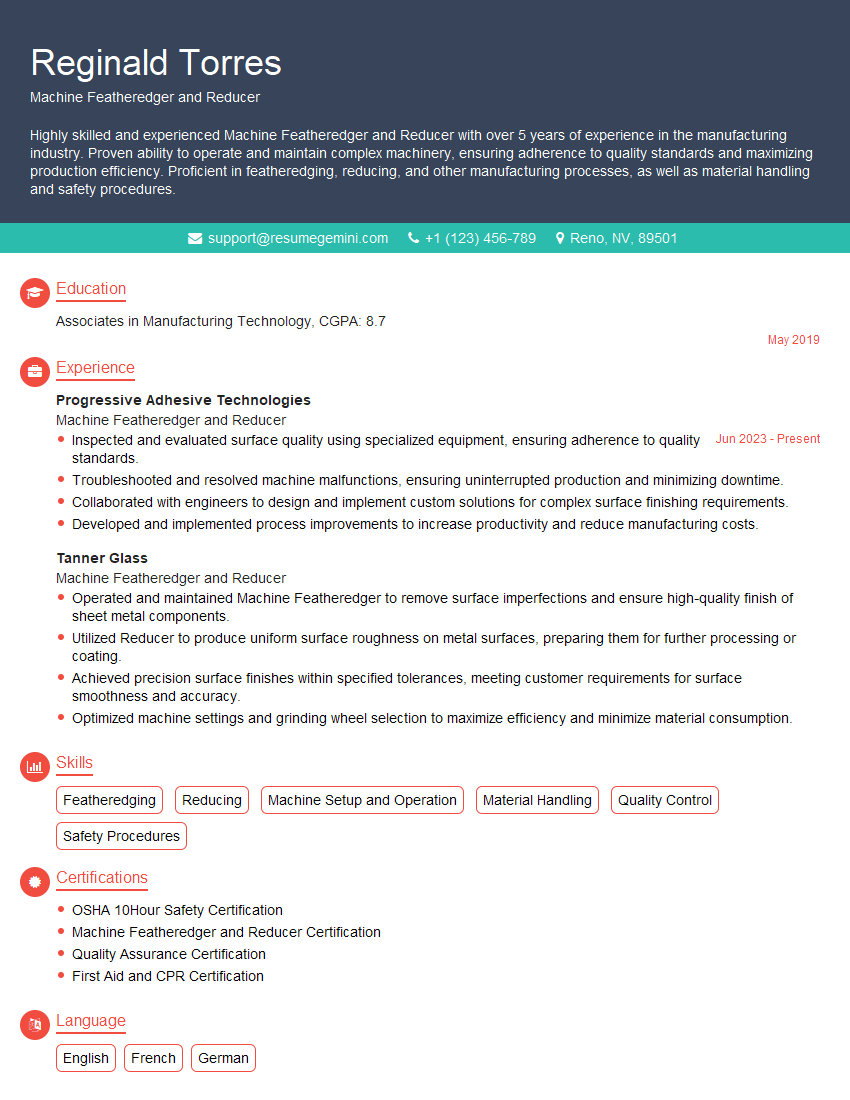

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Featheredger and Reducer

1. What are the key components of a machine featheredger and reducer?

The key components of a machine featheredger and reducer include:

- A cutter head with carbide-tipped blades

- A guide fence

- A depth adjustment knob

- A dust collection port

- A power switch

2. How do you adjust the depth of cut on a machine featheredger?

Adjusting Depth of Cut

- Locate the depth adjustment knob on the machine.

- Turn the knob clockwise to increase the depth of cut.

- Turn the knob counterclockwise to decrease the depth of cut.

Measuring Depth of Cut

- Use a ruler or measuring tape to measure the distance between the cutter head and the guide fence.

- Adjust the depth of cut until the desired measurement is achieved.

3. What are the safety precautions that should be taken when operating a machine featheredger?

When operating a machine featheredger, it is important to take the following safety precautions:

- Wear safety glasses and earplugs.

- Keep your hands away from the cutter head.

- Do not operate the machine if it is damaged.

- Unplug the machine before performing any maintenance.

4. How do you troubleshoot a machine featheredger that is not cutting properly?

If a machine featheredger is not cutting properly, there are a few things you can check:

- Check the cutter head for any damage or dull blades.

- Check the guide fence for any misalignment.

- Check the depth adjustment knob to make sure it is set correctly.

- Check the dust collection port for any clogs.

5. What are the different types of materials that can be featheredged with a machine?

A machine featheredger can be used to featheredge a variety of materials, including:

- Wood

- Laminate

- Plastic

- Metal

6. What is the difference between a machine featheredger and a hand featheredger?

- Power source: Machine featheredgers are powered by electricity, while hand featheredgers are powered by hand.

- Cutting speed: Machine featheredgers cut faster than hand featheredgers.

- Accuracy: Machine featheredgers are more accurate than hand featheredgers.

- Cost: Machine featheredgers are more expensive than hand featheredgers.

7. What are the advantages of using a machine featheredger?

- Faster cutting speed: Machine featheredgers cut faster than hand featheredgers, which can save you time on your projects.

- Greater accuracy: Machine featheredgers are more accurate than hand featheredgers, which can help you achieve a more professional-looking finish.

- Less effort: Machine featheredgers require less effort to use than hand featheredgers, which can reduce fatigue and make your job easier.

8. What are the disadvantages of using a machine featheredger?

- Higher cost: Machine featheredgers are more expensive than hand featheredgers.

- Larger size: Machine featheredgers are larger than hand featheredgers, which can make them more difficult to store and transport.

- More noise: Machine featheredgers are louder than hand featheredgers, which can be a nuisance if you are working in a quiet environment.

9. How do you maintain a machine featheredger?

To maintain a machine featheredger, you should:

- Clean the machine after each use.

- Oil the machine regularly.

- Sharpen the blades when they become dull.

- Inspect the machine for any damage before each use.

10. What are the most common problems that you encounter when using a machine featheredger?

The most common problems that I encounter when using a machine featheredger are:

- The cutter head is not cutting properly.

- The guide fence is not aligned properly.

- The depth adjustment knob is not set correctly.

- The dust collection port is clogged.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Featheredger and Reducer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Featheredger and Reducer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Machine Operation

Operate a machine featheredger and reducer to smooth and blend transitions between different surfaces, such as drywall and ceilings.

2. Surface Preparation

Prepare surfaces by cleaning, sanding, and applying primers or bonding agents.

3. Finishing

Apply coatings or finishes to surfaces using a machine featheredger to achieve a smooth, seamless finish.

4. Equipment Maintenance

Maintain and clean machine featheredger and reducer, ensuring optimal performance and safety.

5. Material Management

Manage the supply of materials, ensuring timely availability and minimizing waste.

6. Quality Control

Inspect and evaluate the quality of finished surfaces, identifying and correcting any defects or imperfections.

Interview Tips

To ace an interview for the Machine Featheredger and Reducer position, candidates should:

1. Research the Company and Industry

Demonstrate familiarity with the company’s services, industry trends, and the specific job requirements.

2. Highlight Relevant Experience and Skills

Emphasize experience in operating and maintaining machine featheredgers and reducers, surface preparation, finishing techniques, and quality control.

3. Showcase Attention to Detail

Convey a keen eye for detail and precision in surface finishing, ensuring smooth and seamless transitions.

4. Technical Knowledge

Demonstrate a solid understanding of machine featheredger operations, including troubleshooting common issues and maximizing productivity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Featheredger and Reducer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.