Feeling lost in a sea of interview questions? Landed that dream interview for Machine Feeder Floorperson but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Feeder Floorperson interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

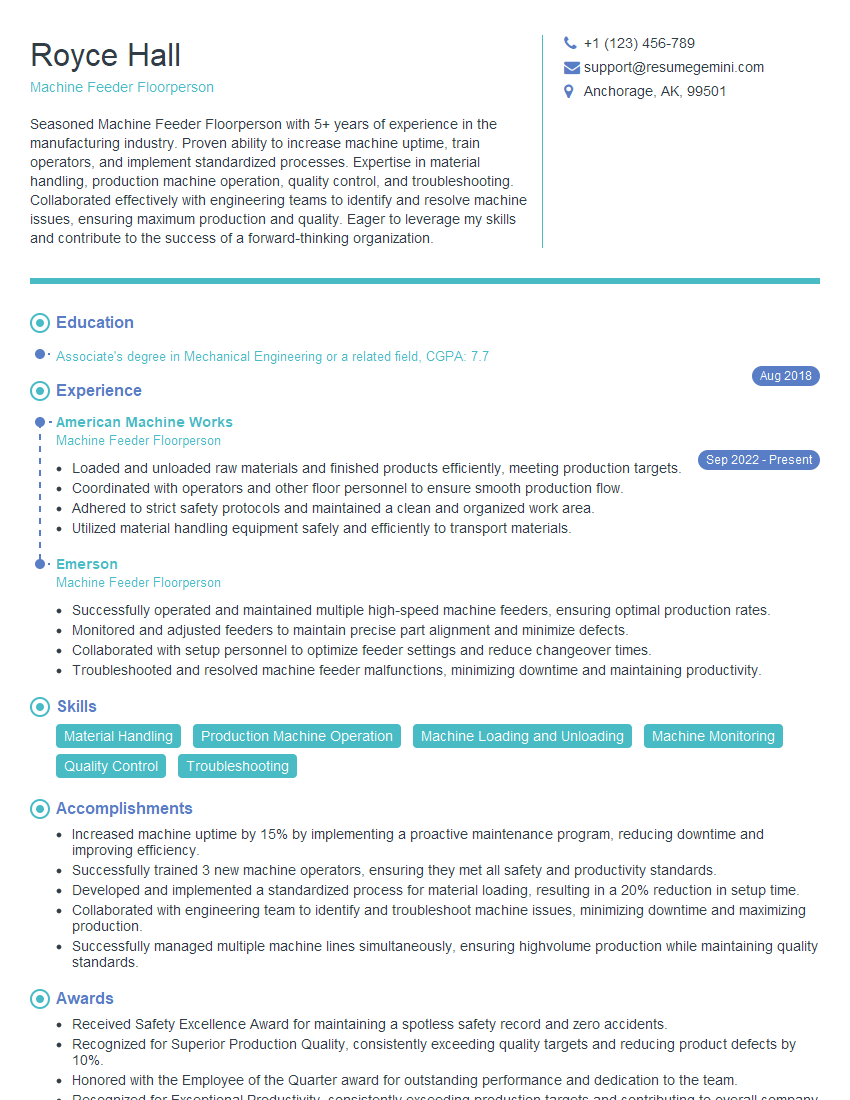

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Feeder Floorperson

1. What are the different types of feeders used in manufacturing processes?

There are various types of feeders used in manufacturing processes, including:

- Vibrating feeders: These feeders use vibrations to move parts or materials along a conveyor.

- Belt feeders: These feeders use a continuous belt to move parts or materials along a conveyor.

- Screw feeders: These feeders use a rotating screw to move parts or materials along a conveyor.

- Hopper feeders: These feeders use a hopper to store and dispense parts or materials into a conveyor.

- Picker feeders: These feeders use a mechanical arm or gripper to pick and place parts or materials into a conveyor.

2. What are the key factors to consider when selecting a feeder for a particular application?

Factors to consider when selecting a feeder

- Type of part or material being fed

- Size and shape of the part or material

- Required feed rate

- Accuracy and precision required

- Environmental conditions

- Cost and maintenance requirements

Example:

- For small, delicate parts, a picker feeder may be the best option due to its accuracy and precision.

- For large, heavy parts, a belt feeder may be more suitable due to its ability to handle high loads.

3. How do you troubleshoot common feeder problems?

To troubleshoot common feeder problems, I would follow these steps:

- Identify the problem

- Gather information about the feeder, the material being fed, and the process

- Inspect the feeder for any visible damage or wear

- Check the electrical connections and settings

- Observe the feeder in operation and look for any irregularities

- Make adjustments or repairs as necessary

- Test the feeder to ensure the problem has been resolved

4. What are the safety precautions that should be taken when working with feeders?

When working with feeders, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep hands and other body parts away from moving parts.

- Do not operate the feeder if it is damaged or malfunctioning.

- Follow all manufacturer instructions and warnings.

- Be aware of the surroundings and potential hazards.

5. What maintenance tasks are required to keep a feeder operating properly?

To keep a feeder operating properly, it is important to perform the following maintenance tasks:

- Regularly inspect the feeder for wear and damage.

- Clean the feeder and remove any debris or buildup.

- Lubricate moving parts according to the manufacturer’s instructions.

- Check the electrical connections and settings.

- Perform any necessary repairs or adjustments.

6. Describe your experience with setting up and calibrating feeders.

In my previous role, I was responsible for setting up and calibrating a variety of feeders, including vibrating feeders, belt feeders, and screw feeders. I have experience with both manual and automated feeders and I am familiar with the various types of adjustments and calibrations that are required to ensure accurate and reliable operation. I am also familiar with the use of measuring equipment and software to verify the accuracy of feeders.

7. What is the difference between a vibratory feeder and a belt feeder?

Vibratory feeder

- Uses vibrations to move parts or materials

- Suitable for small, delicate parts

- Accurate and precise

Belt feeder

- Uses a continuous belt to move parts or materials

- Suitable for large, heavy parts

- Can handle high loads

8. Explain the process of troubleshooting a feeder that is not feeding properly.

To troubleshoot a feeder that is not feeding properly, I would follow these steps:

- Identify the problem

- Gather information about the feeder, the material being fed, and the process

- Inspect the feeder for any visible damage or wear

- Check the electrical connections and settings

- Observe the feeder in operation and look for any irregularities

- Make adjustments or repairs as necessary

- Test the feeder to ensure the problem has been resolved

9. What are the different types of sensors used in feeders?

The different types of sensors used in feeders include:

- Proximity sensors: These sensors detect the presence of an object without making contact with it.

- Photoelectric sensors: These sensors use light to detect the presence of an object.

- Limit switches: These sensors are used to detect the position of an object.

- Pressure sensors: These sensors are used to detect the presence of pressure.

- Temperature sensors: These sensors are used to detect the temperature of an object.

10. How do you ensure that the feeder is feeding the correct amount of material?

To ensure that the feeder is feeding the correct amount of material, I would use the following methods:

- Calibrate the feeder according to the manufacturer’s instructions.

- Use a scale or other measuring device to verify the amount of material being fed.

- Monitor the feeder’s performance over time and make adjustments as necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Feeder Floorperson.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Feeder Floorperson‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Feeder Floorperson is responsible for ensuring the smooth operation of production machinery by feeding materials into machines, monitoring the production process, and performing basic troubleshooting.

1. Feeding materials into machines

This involves manually or automatically loading raw materials or components into the machine’s hopper or feed tray.

- Ensuring that the materials are correctly aligned and positioned for proper processing.

- Adjusting the feeding rate to optimize production efficiency and prevent jams or malfunctions.

2. Monitoring the production process

Observing the machine’s operation to detect any irregularities or deviations from normal parameters.

- Checking for signs of wear, damage, or leaks that could affect machine performance.

- Monitoring gauges, displays, and other instruments to ensure that the machine is operating within acceptable limits.

3. Performing basic troubleshooting

Identifying and resolving minor issues that arise during the production process.

- Clearing jams, adjusting settings, or replacing simple components following established procedures.

- Reporting any serious malfunctions or problems that require the attention of a maintenance technician.

4. Maintaining a clean and organized work area

Ensuring that the work area is free from debris, spills, or other hazards.

- Cleaning and lubricating machines and equipment as needed.

- Following safety protocols and maintaining a safe working environment.

Interview Tips

Preparing for a job interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some interview tips to help you ace your interview for a Machine Feeder Floorperson position:

1. Research the company and the position

Before the interview, take some time to research the company, their products or services, and the specific role you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website and social media pages.

- Read news articles and industry publications about the company.

- Review the job description and make note of the key qualifications and responsibilities.

2. Practice answering common interview questions

There are certain interview questions that are commonly asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practicing your answers to these questions will help you feel more confident and prepared during the interview.

- Use the STAR method to answer behavioral interview questions.

- Prepare specific examples that highlight your skills and experience.

- Practice answering questions out loud, either in front of a mirror or with a friend or family member.

3. Dress appropriately and arrive on time

First impressions matter, so it’s important to dress appropriately for your interview. You don’t need to wear a suit, but you should choose clothing that is clean, pressed, and professional. It’s also important to arrive on time for your interview. Punctuality shows that you respect the interviewer’s time.

- Choose clothing that is appropriate for the company culture.

- Arrive for your interview 5-10 minutes early.

- If you’re running late, call or email the interviewer to let them know.

4. Be yourself and be enthusiastic

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be enthusiastic about the position and the company, and let the interviewer know why you’re the best person for the job.

- Answer questions honestly and authentically.

- Share your knowledge and experience with confidence.

- Ask thoughtful questions at the end of the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Feeder Floorperson interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!