Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Feller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

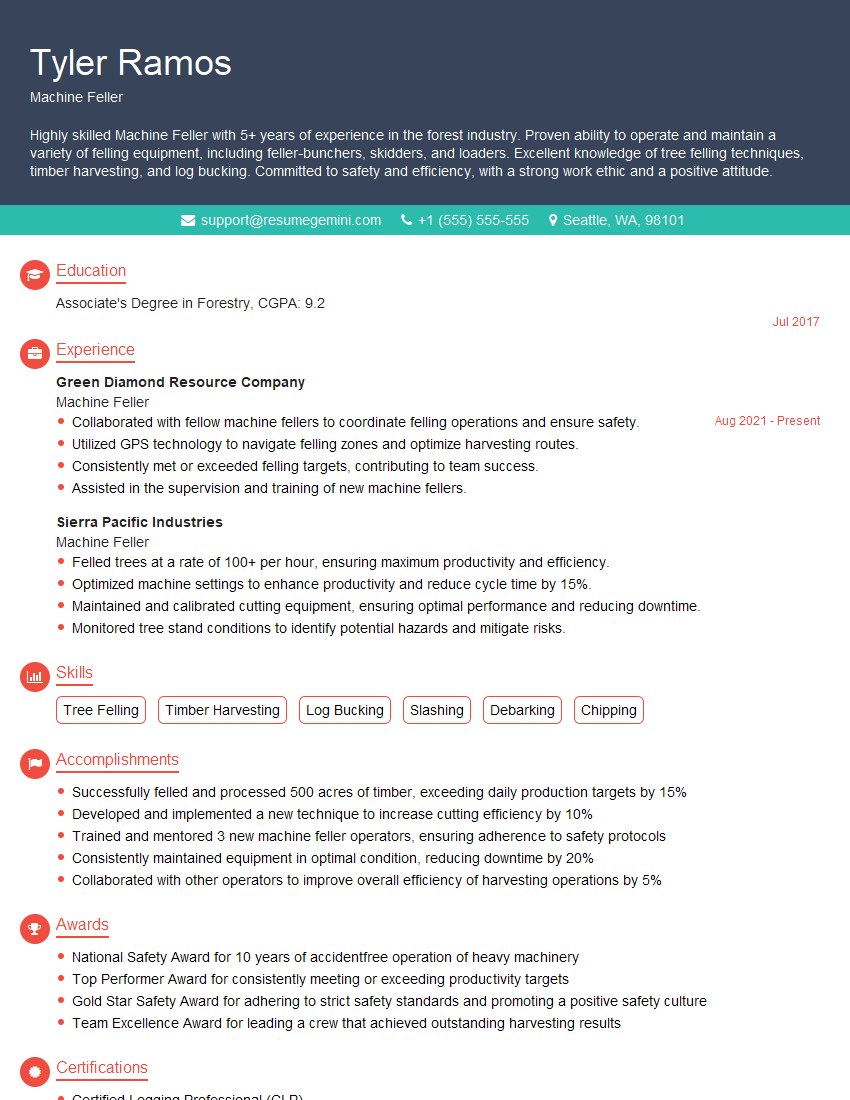

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Feller

1. What are the different types of felling machines and their applications?

- Single-grip harvesters: These are used for delimbing and cutting trees in one pass. They are typically used in areas with steep slopes or dense vegetation.

- Dual-grip harvesters: These are used for felling and delimbing trees in two separate passes. They are typically used in areas with moderate slopes or clear-cut areas.

- Processor feller bunchers: These are used for felling, delimbing, and bucking trees in a single pass. They are typically used in areas with high production requirements.

- Tractors: Tractors are used to skid logs to a landing area. They can also be used to pull stumps and other debris.

- Forwarders: Forwarders are used to transport logs from a landing area to a mill or other destination.

2. What are the safety precautions that must be taken when operating a felling machine?

Personal protective equipment

- Hard hat

- Safety glasses

- Ear protection

- Gloves

- Boots with steel toes

Machine operation

- Inspect the machine before each use and report any damage or defects to a supervisor.

- Operate the machine only from the designated operating position.

- Be aware of your surroundings and keep a safe distance from other people and objects.

- Never leave the machine running unattended.

- Shut off the engine and remove the key before performing any maintenance or repairs.

- Follow all safety instructions and procedures posted on the machine or in the operator’s manual.

3. What are the different types of felling heads and their advantages and disadvantages?

- Shear felling heads: These are used to cut trees by shearing through the stem. They are typically used in areas with high production requirements.

- Saw felling heads: These are used to cut trees by sawing through the stem. They are typically used in areas with moderate production requirements.

- Disc felling heads: These are used to cut trees by throwing a disc at the stem. They are typically used in areas with high production requirements.

- Advantages of shear felling heads: High production rates, low maintenance costs, can handle large trees.

- Disadvantages of shear felling heads: Can damage the wood fiber, not suitable for all tree species.

- Advantages of saw felling heads: Clean cuts, less damage to the wood fiber, can handle all tree species.

- Disadvantages of saw felling heads: Lower production rates, higher maintenance costs, not suitable for large trees.

- Advantages of disc felling heads: High production rates, can handle large trees, clean cuts.

- Disadvantages of disc felling heads: High maintenance costs, can be dangerous to operate.

4. What are the different factors that affect the productivity of a felling machine?

- Tree size and species

- Terrain conditions

- Weather conditions

- Machine operator experience

- Machine maintenance

5. What are the different types of felling patterns and when are they used?

- Clear-cutting: This is the most common felling pattern. It involves removing all of the trees from an area.

- Selective cutting: This involves removing only certain trees from an area. It is typically used to improve the health of a forest or to create a desired habitat for wildlife.

- Coppice cutting: This involves cutting trees close to the ground to encourage the growth of new shoots. It is typically used to produce firewood or other small wood products.

- Thinning: This involves removing some of the trees from an area to improve the growth of the remaining trees. It is typically used to increase the yield of timber or to improve the health of a forest.

6. What are the different types of forest management practices and how do they affect felling operations?

- Even-aged management: This involves managing a forest as a single unit. All of the trees in an even-aged forest are the same age.

- Uneven-aged management: This involves managing a forest as a collection of individual trees. Trees in an uneven-aged forest are of different ages.

- Sustainable forest management: This involves managing a forest to meet the needs of the present without compromising the ability of future generations to meet their own needs.

- Forest management practices can affect felling operations by determining the size, species, and density of the trees in a forest.

7. What are the different types of environmental regulations that apply to felling operations?

- The Clean Water Act

- The Clean Air Act

- The Endangered Species Act

- The National Forest Management Act

- The Forest and Rangeland Renewable Resources Planning Act

- These regulations can affect felling operations by restricting the use of certain chemicals, requiring the use of certain equipment, and limiting the amount of timber that can be harvested.

8. What are the different types of equipment that can be used to assist with felling operations?

- Skidders

- Forwarders

- Grapples

- Log loaders

- Chippers

- This equipment can help to improve the efficiency and safety of felling operations.

9. What are the different types of training that are required for felling machine operators?

- Safety training

- Machine operation training

- Environmental awareness training

- First aid training

- This training can help to ensure that felling machine operators are qualified to operate their machines safely and efficiently.

10. What are the different types of career opportunities that are available for felling machine operators?

- Logger

- Forester

- Timber buyer

- Timber scaler

- Log truck driver

- Heavy equipment operator

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Feller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Feller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Fellers are responsible for operating heavy machinery to cut down and prepare trees for logging. They work in a variety of environments, including forests, plantations, and clear-cut areas. Their primary objective is to ensure that trees are felled safely and efficiently, with minimal damage to the surrounding environment.

- Operate heavy machinery, such as feller bunchers, skidders, and delimbers, to cut down trees and prepare them for logging

- Identify and assess trees for felling, considering factors such as size, species, and terrain

- Plan and execute felling operations, taking into account safety regulations and environmental considerations

- Operate and maintain machinery, ensuring that it is in good working order and meets safety standards

- Monitor felling operations and make adjustments as needed to ensure efficiency and safety

- Work as part of a team, coordinating with other loggers and support staff

- Follow safety regulations and protocols to minimize risks and ensure a safe working environment

- Maintain a clean and organized work area to prevent accidents and promote efficiency

- Keep up-to-date on industry best practices and advancements in logging technology

Interview Tips

Preparing for a job interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview for a Machine Feller position:

1. Research the Company and Position

Take the time to learn about the company you are applying to, including their values, mission, and safety record. Research the specific requirements of the Machine Feller position, such as required certifications and experience.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in a clear and concise manner that highlights your skills and experience.

3. Highlight Your Safety and Environmental Awareness

Safety is paramount in the logging industry. Emphasize your commitment to safety by describing your experience with safety regulations and protocols. Additionally, discuss your understanding of environmental regulations and your commitment to sustainable logging practices.

4. Demonstrate Your Technical Skills

Machine Fellars must have a strong understanding of heavy machinery operation and maintenance. In your interview, be prepared to discuss your experience with different types of logging equipment and your ability to troubleshoot and repair common problems.

5. Show Your Teamwork and Communication Skills

Machine Fellars often work as part of a team. Highlight your teamwork and communication skills by providing examples of how you have successfully worked with others to achieve common goals.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for your interview and arrive on time. This shows that you are serious about the position and respectful of the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Feller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!