Are you gearing up for a career in Machine Filler Shredder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Filler Shredder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

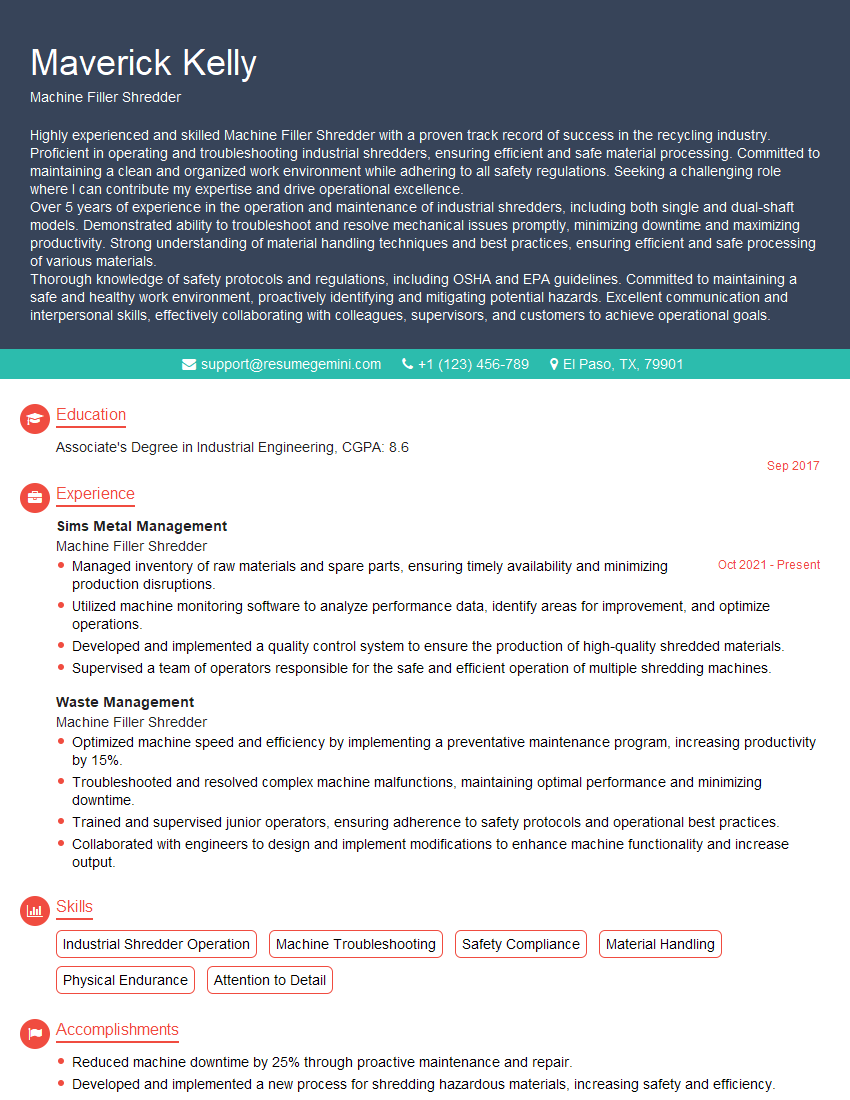

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Filler Shredder

1. Are you aware of different types of machine filler shredders available in the market?

Yes, I am aware of the different types of machine filler shredders available in the market. They include:

- Granulators

- Shredders

- Pulverizers

- Mills

2. What are the key factors to consider when selecting a machine filler shredder?

Factors to Consider Before Buying a Machine Filler Shredder

- Size and Capacity of Shredder.

- Required Shred Size.

- Type of Material to Be Shredded.

- Shredder Construction.

- Level of Noise.

How to Select the Right Shredder

- Contact the manufacturers.

- Read reviews and testimonials.

- Consider your budget.

3. What are the safety precautions that must be taken while operating a machine filler shredder?

The safety precautions that must be taken while operating a machine filler shredder include:

- Always wear safety glasses, earplugs, and gloves when operating the shredder.

- Never put your hands or fingers into the shredder while it is running.

- Keep the shredder away from children and pets.

- Do not overload the shredder.

- Unplug the shredder before cleaning or servicing it.

4. What are the common problems that can occur with machine filler shredders and how can they be resolved?

Some common problems that can occur with machine filler shredders include:

- Shredder is not cutting properly: This can be caused by a dull blade or a buildup of material on the blade. To resolve this issue, you can sharpen or replace the blade and clean the shredder.

- Shredder is making a lot of noise: This can be caused by a loose belt or a worn bearing. To resolve this issue, you can tighten the belt or replace the bearing.

- Shredder is overheating: This can be caused by a lack of lubrication or a blocked air vent. To resolve this issue, you can lubricate the shredder and clean the air vent.

5. How do you maintain a machine filler shredder to ensure it is operating at optimal levels?

To maintain a machine filler shredder and ensure it is operating at optimal levels, you should:

- Clean the shredder regularly to remove any buildup of material.

- Lubricate the shredder according to the manufacturer’s instructions.

- Sharpen or replace the blade when necessary.

- Inspect the shredder regularly for any signs of damage.

6. What is the difference between a granulator and a shredder?

A granulator is a machine that breaks down materials into small, uniform granules. A shredder is a machine that breaks down materials into smaller pieces, but the pieces are not necessarily uniform in size.

7. What are the advantages of using a machine filler shredder?

- Increased efficiency

- Reduced labor costs

- Improved product quality

- Reduced environmental impact

8. What are the different types of materials that can be shredded using a machine filler shredder?

Machine filler shredders can be used to shred a wide variety of materials, including paper, plastic, metal, wood, and rubber.

9. What is the difference between a single-shaft shredder and a dual-shaft shredder?

A single-shaft shredder has one rotating shaft with blades that cut the material. A dual-shaft shredder has two rotating shafts with blades that intermesh, which provides a more aggressive shredding action.

10. What are the safety features that should be considered when selecting a machine filler shredder?

- Emergency stop button

- Interlocking safety switches

- Soundproofing

- Vibration dampening

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Filler Shredder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Filler Shredder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Filler Shredder is a skilled professional responsible for filling and shredding paper and other materials using industrial machinery. The role requires proficiency in operating industrial machines, maintaining a clean and safe work environment, and performing inspections.

1. Filling and Shredding

The primary responsibility of a Machine Filler Shredder is to fill and shred paper and other materials. This involves operating industrial machines that shred and cut materials into smaller pieces. The machine filler shredder needs to be adept at loading and unloading materials, adjusting machine settings, and ensuring the efficient operation of the equipment.

- Load paper and other materials into shredder machines

- Operate shredder machines to cut and shred materials

- Unload shredded materials from machines

2. Machine Operation and Maintenance

The machine filler shredder is responsible for the proper operation and maintenance of shredder machines. This includes performing regular inspections, cleaning, and maintaining the equipment to ensure optimal performance.

- Inspect shredder machines for wear and tear

- Clean shredder blades and other components

- Perform maintenance and repairs on shredder machines

3. Safety and Compliance

The machine filler shredder must adhere to safety protocols and ensure compliance with relevant regulations. This includes wearing protective gear, following proper procedures, and maintaining a clean and safe work environment.

- Follow safety procedures while operating shredder machines

- Wear appropriate protective gear

- Comply with environmental regulations related to shredding

4. Quality Control

The machine filler shredder is responsible for ensuring the quality of shredded materials. This includes inspecting the output, identifying any defects, and taking corrective actions to maintain quality.

- Inspect shredded materials for defects

- Identify and correct any problems with shredded materials

- Maintain records of shredded materials

Interview Tips

Preparing thoroughly for your Machine Filler Shredder interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Know the Job and the Company

Before the interview, research the company and the specific position you’re applying for. Understand the company’s products, services, and values. Familiarize yourself with the key responsibilities and qualifications for the Machine Filler Shredder role.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses?”. Practice delivering your answers concisely and confidently.

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the Machine Filler Shredder role. Quantify your accomplishments with specific metrics whenever possible, for example, “Reduced machine downtime by 15% through proactive maintenance.”

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you’re genuinely interested in the position and the company. Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with the knowledge of Machine Filler Shredder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Filler Shredder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini