Feeling lost in a sea of interview questions? Landed that dream interview for Machine Greaser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Greaser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

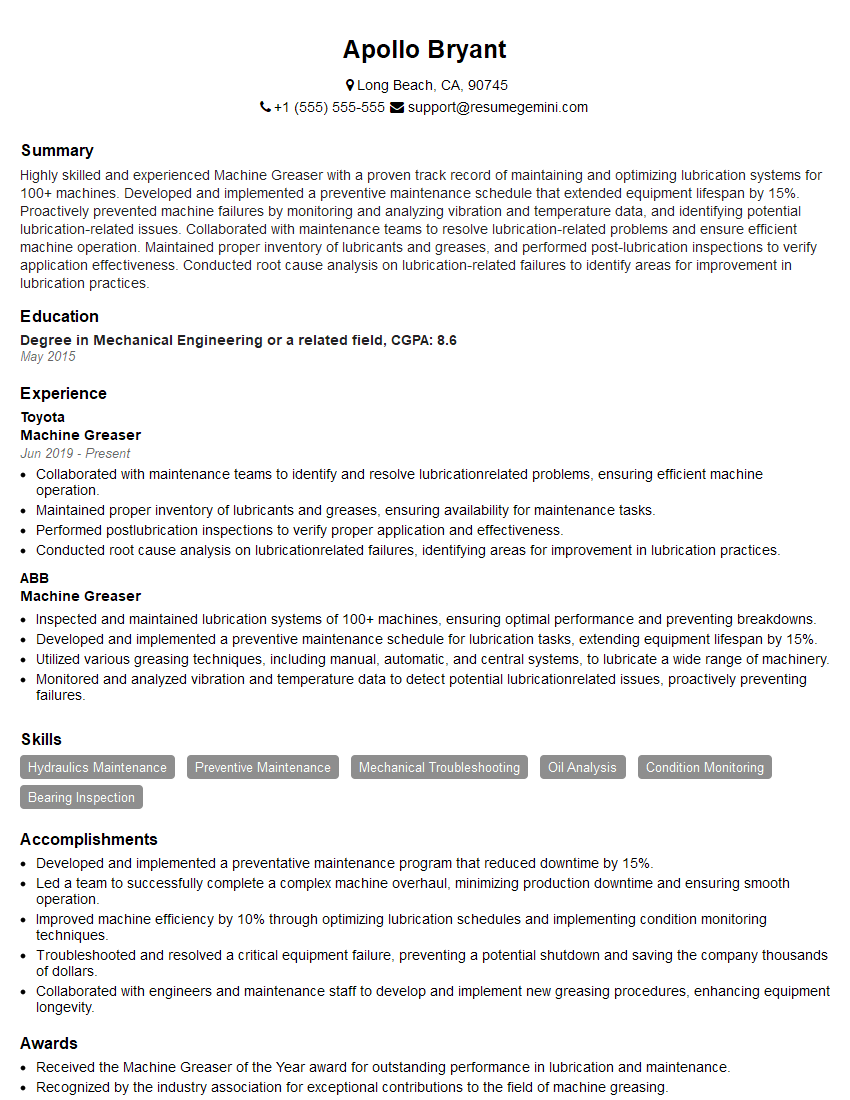

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Greaser

1. What are the different types of lubricants used in machinery?

Lubricants are substances that are used to reduce friction and wear between moving parts. There are many different types of lubricants, each with its own unique properties. Some of the most common types of lubricants include:

- Oils: Oils are the most common type of lubricant. They are made from a base oil, such as mineral oil or synthetic oil, and can be blended with additives to improve their performance.

- Greases: Greases are semi-solid lubricants that are made from a base oil and a thickener. They are often used in applications where oil would be too fluid, such as in bearings or gears.

- Solid lubricants: Solid lubricants are dry lubricants that are made from a solid material, such as graphite or molybdenum disulfide. They are often used in applications where other types of lubricants would be ineffective, such as in extreme temperatures or vacuum environments.

2. What are the different methods of applying lubricants?

Manual lubrication

- Using an oil can or grease gun to apply lubricant directly to the moving parts.

Automatic lubrication

- Using a centralised lubrication system to automatically apply lubricant to the moving parts.

3. What are the signs and symptoms of inadequate lubrication?

Inadequate lubrication can lead to a number of signs and symptoms, including:

- Increased friction and wear

- Overheating

- Noise

- Vibration

- Premature failure

4. What are the consequences of over-lubrication?

Over-lubrication can also lead to a number of problems, including:

- Attracting dirt and contaminants

- Interfering with the operation of the machine

- Causing leaks

- Wasting lubricant

5. What are the safety precautions that must be taken when handling lubricants?

Lubricants can be hazardous to health if they are not handled properly. Some of the safety precautions that must be taken when handling lubricants include:

- Wearing gloves and eye protection

- Avoiding contact with skin and eyes

- Not eating or drinking in areas where lubricants are being used

- Storing lubricants in a safe place

- Disposing of lubricants properly

6. What are the environmental hazards of lubricants?

Lubricants can also pose a hazard to the environment if they are not disposed of properly. Some of the environmental hazards of lubricants include:

- Water pollution

- Soil contamination

- Air pollution

7. What are the different types of lubrication systems?

- Manual lubrication systems

- Semi-automatic lubrication systems

- Automatic lubrication systems

- Centralized lubrication systems

8. What are the advantages of using a centralized lubrication system?

- Reduced maintenance costs

- Improved machine reliability

- Reduced downtime

- Increased production efficiency

9. What are the different types of grease fittings?

- Zerk fittings

- Button head fittings

- Pipe thread fittings

- Compression fittings

10. What are the different types of grease guns?

- Manual grease guns

- Air-operated grease guns

- Electric grease guns

- Battery-operated grease guns

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Greaser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Greaser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Greasers are responsible for the lubrication and maintenance of machinery within an industrial environment. Their primary focus is to ensure that all machines are functioning efficiently and without any interruptions caused by inadequate lubrication.

1. Machine Lubrication

The primary responsibility of a Machine Greaser is to lubricate various machine components such as bearings, gears, and chains. They must possess a thorough understanding of different types of lubricants and their applications to select the most appropriate one for each machine. Accurate and timely lubrication helps prevent wear and tear, reduces friction, and extends the life of the equipment.

- Apply lubricants to machine components according to established schedules and procedures

- Monitor lubrication levels and refill as needed

2. Machine Maintenance

In addition to lubrication, Machine Greasers are also responsible for performing basic maintenance tasks on the machinery they service. This may involve inspecting machines for signs of wear or damage, identifying potential issues, and taking preventive measures to avoid breakdowns.

- Inspect machines regularly for leaks, vibrations, or other signs of trouble

- Tighten bolts and adjust components as necessary

3. Equipment Monitoring

Machine Greasers are often entrusted with the task of monitoring the performance of the machines they service. They observe and record the machine’s operating parameters, such as temperature, pressure, and sound levels. Any deviations from normal operating conditions can indicate potential problems, allowing the Machine Greaser to take prompt action.

- Monitor machine performance parameters and document any irregularities

- Report any unusual behaviour or potential issues to maintenance personnel

4. Safety and Housekeeping

Maintaining a safe and clean work environment is crucial for Machine Greasers. They must adhere to all safety regulations, wear appropriate protective gear, and ensure that the surrounding area is free from hazards.

- Follow established safety procedures and use appropriate personal protective equipment

- Maintain a clean and organized work area

Interview Tips

Preparing for a Machine Greaser interview requires a combination of technical knowledge and an understanding of the role’s responsibilities. Here are some key tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, take the time to research the company you are applying to and the industry in which they operate. This knowledge will help you understand the company’s culture, business practices, and the specific challenges and opportunities within the industry.

2. Review the Job Description Thoroughly

Carefully read through the job description for the Machine Greaser position. Identify the key responsibilities and qualifications required for the role. This will help you tailor your answers to the specific requirements of the position.

3. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in lubrication, machine maintenance, and equipment monitoring. Provide specific examples of your accomplishments and how your expertise has contributed to the effective operation of machinery.

4. Demonstrate Your Safety Awareness

Safety is paramount in the role of a Machine Greaser. Highlight your understanding of safety regulations and procedures. Share examples of how you have prioritized safety in your previous work experience and describe your commitment to maintaining a safe work environment.

5. Prepare for Common Interview Questions

Anticipate common interview questions related to the role of a Machine Greaser. Some typical questions include:

- Tell me about your experience in lubricating and maintaining industrial machinery.

- How do you ensure that machines operate at optimal efficiency?

- Describe a time when you identified a potential machine issue and took proactive steps to prevent a breakdown.

6. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your genuine interest in the role and the company. Prepare a few questions that relate to the specific job responsibilities, the company’s growth plans, or the industry trends. This shows that you are engaged and eager to learn more about the opportunity.

7. Be Confident and Enthusiastic

Confidence and enthusiasm are key. Believe in your abilities and convey your passion for the role of a Machine Greaser. Let the interviewer know that you are excited about the opportunity and eager to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Greaser interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.