Are you gearing up for an interview for a Machine Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

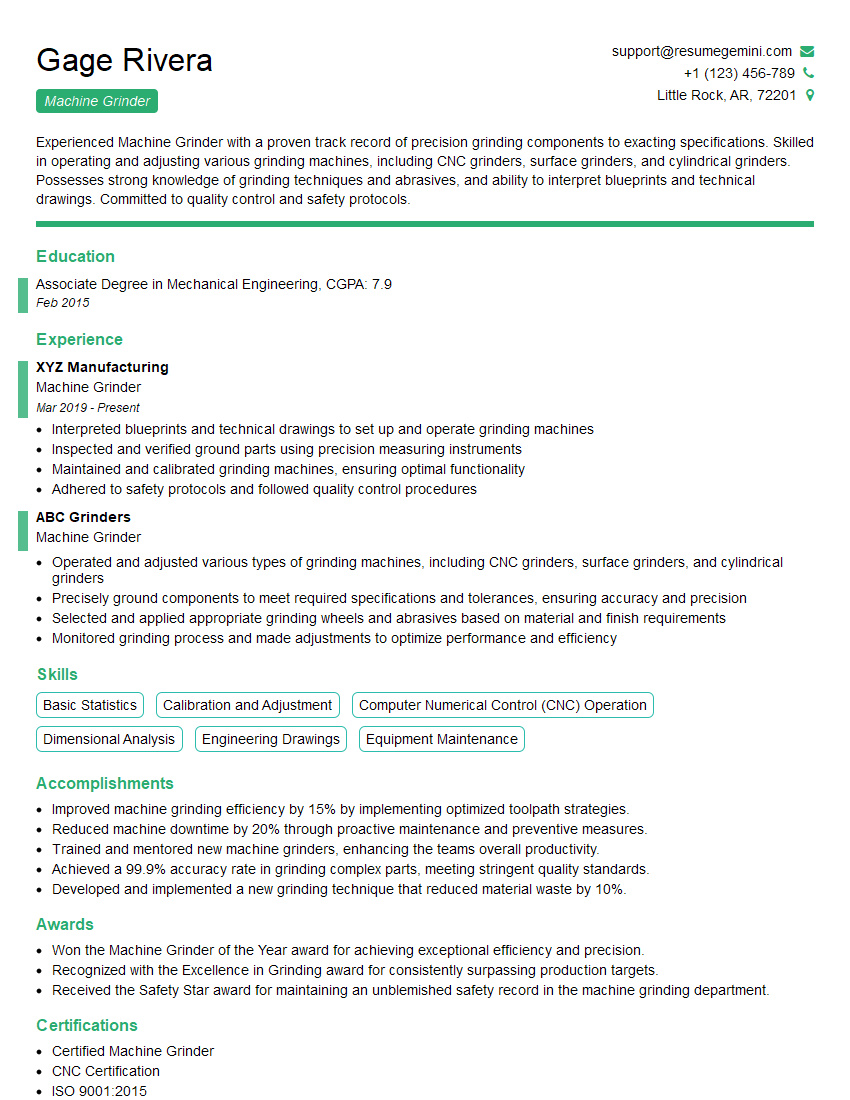

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Grinder

1. Describe the different types of grinding machines you have used in the past?

In my previous role, I operated various grinding machines, including:

- Centerless grinders for producing cylindrical parts with high precision and roundness

- Internal grinders for machining the interior surfaces of cylindrical and non-cylindrical workpieces

- Surface grinders for achieving flat, smooth surfaces on metal components

- Cylindrical grinders for grinding external cylindrical surfaces, tapers, and shoulders

2. Explain the process of setting up a grinding machine for a specific job?

Pre-Production Planning

- Review blueprints and understand the specifications of the workpiece, tolerances, and surface finish requirements

- Select the appropriate grinding machine, tooling, and abrasives based on material type, shape, and required precision

Machine Setup

- Mount the workpiece securely on the workholding device

- Install the grinding wheel and adjust its speed, feed rate, and depth of cut

- Set up the coolant system and verify its flow rate and pressure

- Perform trial cuts and make necessary adjustments to optimize cutting parameters

3. How do you ensure the accuracy and precision of the grinding process?

To ensure accuracy and precision, I follow these steps:

- Calibrate the grinding machine regularly to maintain its alignment and stability

- Use high-quality abrasives and tooling to minimize tool wear and maintain consistent grinding performance

- Monitor the grinding process closely and make adjustments as needed to maintain desired dimensions and surface finish

- Inspect the finished workpieces using precision measuring tools, such as micrometers and comparators, to ensure they meet specifications

4. What are the common problems that can occur during grinding and how do you troubleshoot them?

Common problems during grinding include:

- Chattering: Caused by vibration or instability, it can be resolved by adjusting the grinding parameters, balancing the workpiece, or using vibration dampers

- Burning: Occurs due to excessive heat buildup, and can be addressed by reducing the grinding force, increasing the coolant flow, or using a more appropriate abrasive

- Glazing: When the grinding wheel surface becomes clogged, it can be resolved by dressing the wheel or using a different abrasive

- Loading: Occurs when abrasive particles become embedded in the workpiece, and can be fixed by changing the abrasive type, adjusting the grinding parameters, or using a dressing tool

5. Describe your experience in grinding different types of materials?

I have experience grinding various materials, including:

- Metals: Steels (carbon, alloy, stainless), aluminum, and titanium

- Ceramics: Alumina, zirconia, and silicon carbide

- Plastics: Acrylics, polycarbonates, and nylon

- Composites: Glass fiber reinforced plastics, carbon fiber reinforced plastics

6. What are the safety precautions that must be taken when operating a grinding machine?

To ensure safety when operating a grinding machine, I adhere to these precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs

- Securely fasten the workpiece and ensure that all guards are in place before starting the machine

- Maintain a clean and organized work area to minimize tripping hazards

- Never attempt to touch the grinding wheel or workpiece while it is in motion

- Inspect the grinding machine regularly for any signs of damage or wear

7. How do you stay updated on the latest grinding techniques and technologies?

To stay updated on the latest grinding techniques and technologies, I engage in continuous learning through:

- Attending industry conferences and workshops

- Reading technical journals and articles

- Consulting with experts in the field

- Participating in online forums and discussions

8. Describe a time when you had to overcome a challenging situation during grinding?

During the production of precision shafts, we encountered an issue with surface finish quality. After analyzing the process, I identified that the grinding wheel was worn and needed replacement. I promptly replaced the wheel and adjusted the grinding parameters, which resulted in an immediate improvement in surface roughness and dimensional accuracy.

9. How do you work as part of a team in a grinding environment?

In a team environment, I contribute effectively by:

- Communicating clearly and sharing my knowledge with colleagues

- Collaborating on process improvements to enhance productivity and quality

- Assisting team members with their tasks when possible

- Maintaining a positive and supportive work atmosphere

10. Why are you interested in working as a Machine Grinder at our company?

I am eager to join your company as a Machine Grinder because I am impressed by your commitment to producing high-quality products and your focus on innovation. With my expertise in grinding techniques and my dedication to precision, I am confident that I can make a valuable contribution to your team. Moreover, I am excited about the opportunity to learn from experienced professionals and contribute my skills to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Grinders are responsible for operating and maintaining grinding machines to shape and finish metal parts. They must be able to read blueprints and work independently to achieve precise results.

1. Operate Grinding Machines

Machine Grinders are responsible for operating a variety of grinding machines, including surface grinders, cylindrical grinders, and tool and cutter grinders. They must be able to set up and operate these machines to achieve the desired results.

- Set up and operate grinding machines to shape and finish metal parts.

- Use a variety of grinding wheels to achieve the desired results.

- Monitor the grinding process and make adjustments as needed.

2. Maintain Grinding Machines

Machine Grinders must be able to maintain their grinding machines in good working order. This includes performing routine maintenance tasks, such as cleaning and lubricating the machines, and troubleshooting and repairing any problems that may occur.

- Perform routine maintenance tasks, such as cleaning and lubricating grinding machines.

- Troubleshoot and repair any problems that may occur with grinding machines.

- Order and install replacement parts as needed.

3. Inspect and Measure Parts

Machine Grinders must be able to inspect and measure parts to ensure that they meet the required specifications. This includes using a variety of measuring tools, such as micrometers and calipers, to check the dimensions of parts.

- Inspect and measure parts to ensure that they meet the required specifications.

- Use a variety of measuring tools, such as micrometers and calipers, to check the dimensions of parts.

- Make adjustments to the grinding process as needed to ensure that parts meet the required specifications.

4. Work Safely

Machine Grinders must be able to work safely around grinding machines. This includes wearing appropriate safety gear, such as safety glasses and earplugs, and following all safety procedures. They must also be aware of the potential hazards of working with grinding machines and take steps to avoid accidents.

- Wear appropriate safety gear, such as safety glasses and earplugs.

- Follow all safety procedures.

- Be aware of the potential hazards of working with grinding machines and take steps to avoid accidents.

Interview Tips

Preparing for a Machine Grinder interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

The first step to preparing for an interview is to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website to learn more about its history, products, and services.

- Read the job description carefully to understand the specific requirements of the position.

- If possible, try to find out who will be interviewing you and research their background.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Prepare a brief overview of your skills and experience that is relevant to the position.

- Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Be prepared to talk about your experience with grinding machines and other relevant equipment.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview on time or even a few minutes early.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the opportunity to work for their company. Be sure to show the interviewer that you are excited about the position and that you are confident in your abilities.

- Smile and make eye contact with the interviewer.

- Be positive and enthusiastic about your skills and experience.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Grinder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!