Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Installer so you can tailor your answers to impress potential employers.

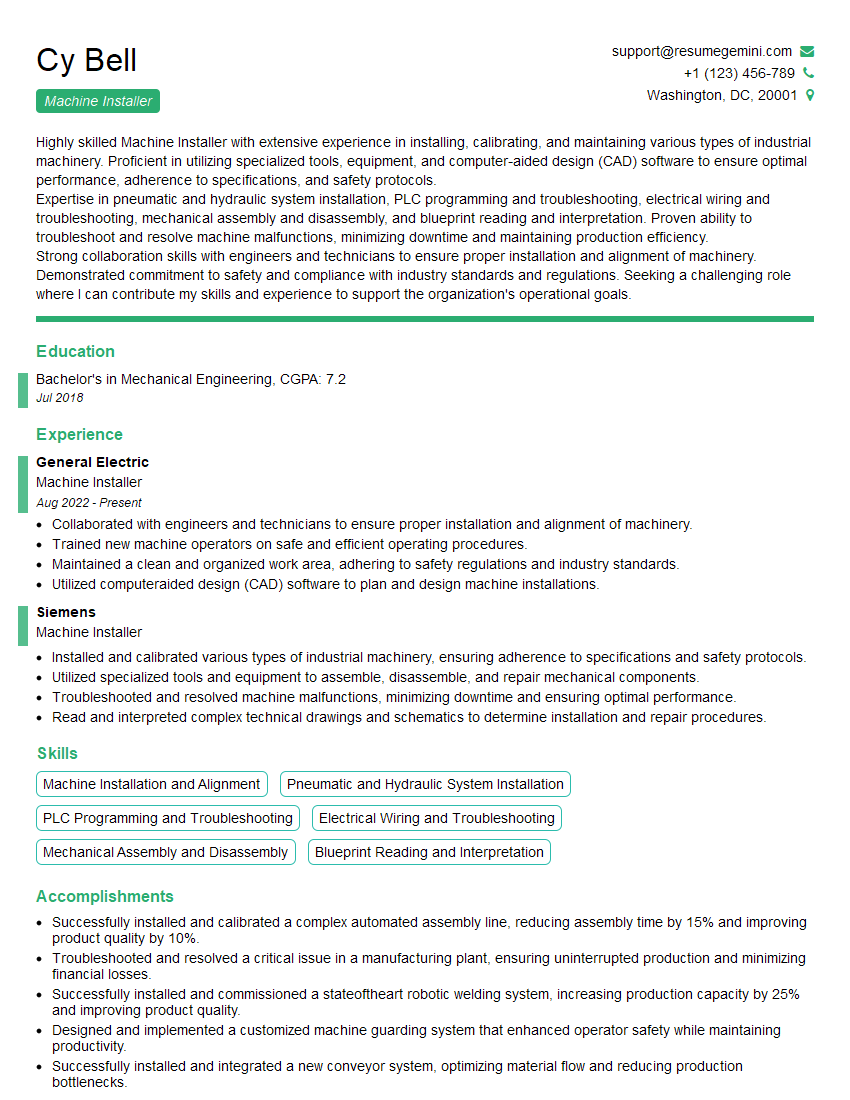

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Installer

1. What are the essential steps you follow while installing a machine?

The essential steps I follow while installing a machine include:

- Preparing the site by ensuring a level and stable surface, proper ventilation, and access to utilities.

- Unpacking and inspecting the machine for any damage or missing components.

- Assembling the machine according to the manufacturer’s instructions, using appropriate tools and techniques.

- Leveling and aligning the machine using precision instruments to ensure accurate operation.

- Connecting utilities such as electricity, water, or compressed air, following safety guidelines.

- Conducting electrical tests to verify proper wiring and grounding.

- Running test cycles to ensure the machine operates smoothly and meets specifications.

- Documenting the installation process, including any adjustments or modifications made.

- Training operators on the machine’s operation and maintenance procedures.

2. Describe your experience in installing and maintaining different types of machines.

Industrial Machinery

- Installed and maintained CNC machines, lathes, and milling machines.

- Troubleshooted and repaired electrical, mechanical, and hydraulic systems.

Medical Equipment

- Installed and calibrated medical imaging equipment, such as MRI and CT scanners.

- Ensured compliance with safety regulations and quality standards.

Automated Systems

- Integrated and installed automated conveyor systems and robotic arms.

- Programmed and configured PLCs and HMIs to control system operation.

3. How do you handle troubleshooting and resolving machine malfunctions?

When troubleshooting machine malfunctions, I follow a systematic approach:

- Identify the symptoms and observe the machine’s behavior.

- Review maintenance logs and consult with operators to gather information.

- Inspect the machine visually and check for loose connections, leaks, or damaged components.

- Use diagnostic tools and instruments to pinpoint the source of the problem.

- Repair or replace faulty components, following the manufacturer’s guidelines.

- Conduct tests to verify the repair and ensure the machine operates properly.

- Document the troubleshooting process and any actions taken.

4. How do you stay up-to-date with advancements in machine installation and maintenance techniques?

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Read technical journals and online resources to keep abreast of industry trends.

- Obtain certifications from manufacturers and industry organizations to demonstrate my expertise.

- Network with other professionals in the field to exchange knowledge and insights.

5. What are the safety precautions you take when installing and maintaining machines?

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Lock out and tag out machines before performing any maintenance or repairs.

- Follow established safety protocols and guidelines.

- Inspect tools and equipment regularly to ensure they are in good condition.

- Maintain a clean and organized work area to prevent accidents.

- Report any potential hazards or unsafe conditions immediately.

6. How do you prioritize multiple machine installations or maintenance requests?

To prioritize multiple machine installations or maintenance requests, I consider the following factors:

- Urgency of the request and potential impact on production.

- Availability of parts and resources.

- Workload and schedule of the team.

- Safety considerations and potential risks.

- Customer requirements and contractual obligations.

7. What are your strengths and weaknesses as a Machine Installer?

Strengths

- Proficient in installing and maintaining a wide range of machines.

- Excellent troubleshooting and problem-solving skills.

- Strong attention to detail and accuracy.

- Ability to work independently and as part of a team.

- Commitment to safety and quality standards.

Weaknesses

- Limited experience with very large or complex machines.

- Need to improve time management skills when handling multiple projects.

8. Why are you interested in this Machine Installer position?

I am excited about the opportunity to join your team as a Machine Installer because:

- The company’s reputation for excellence in the industry.

- The variety of machines and projects I would be involved in.

- The opportunity to contribute my skills and experience to a team of professionals.

- The potential for career growth and development.

9. How do you handle working in a fast-paced environment with tight deadlines?

- Prioritize tasks effectively and allocate time wisely.

- Break down large projects into smaller, manageable steps.

- Communicate regularly with supervisors and team members to manage expectations.

- Stay focused and avoid distractions to maximize productivity.

- Take breaks when necessary to maintain efficiency and accuracy.

10. Do you have any questions for me about the position or the company?

I would like to know more about the following:

- The specific machines and equipment I would be installing and maintaining.

- The size of the maintenance team and the typical workload.

- The company’s commitment to safety and training.

- The opportunities for career advancement within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Installers are responsible for installing, maintaining, and repairing various types of machinery in industrial and manufacturing settings. Their key responsibilities include:

1. Installation and Commissioning:

• Assembling and installing new machines according to specifications and blueprints.

• Connecting and testing electrical, mechanical, and hydraulic systems to ensure proper functionality.

• Commissioning machines for operation by calibrating settings, programming controls, and verifying performance.

2. Maintenance and Repairs:

• Performing regular inspections and preventive maintenance to detect potential issues early.

• Troubleshooting and repairing malfunctions, using specialized tools and equipment.

• Replacing worn or defective components to restore machine efficiency.

3. Calibration and Adjustment:

• Calibrating sensors, instruments, and control systems to ensure accuracy and precision.

• Adjusting machine settings to optimize performance and meet production goals.

4. Safety and Compliance:

• Ensuring that machines are installed and operated in compliance with safety regulations and industry standards.

• Conducting risk assessments and implementing safety measures to minimize accidents and injuries.

• Maintaining documentation and records of installation, maintenance, and repairs for compliance and audit purposes.

Interview Preparation Tips

To ace an interview for a Machine Installer position, candidates should:

1. Research the Company and Role:

• Visit the company website to learn about their business, industry, and culture.

• Read the job description carefully to understand the specific requirements and responsibilities.

2. Highlight Relevant Experience and Skills:

• Emphasize previous experience in machine installation, maintenance, or repair.

• Showcase proficiency in electrical, mechanical, and hydraulic systems troubleshooting.

• Demonstrate strong attention to detail and a commitment to quality workmanship.

3. Practice Common Interview Questions:

• Prepare for questions about your experience, skills, and qualifications.

• Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

Example Outline:

“Tell me about a time you solved a complex machine issue.”

“Situation: Working on a production line, a critical machine malfunctioned…”

“Task: Diagnosed the problem and identified the faulty component…”

“Action: Replaced the component and recalibrated the system…”

“Result: Restored machine functionality, minimizing downtime and maintaining production efficiency.”

4. Dress Professionally and Arrive on Time:

• Make a positive first impression by dressing appropriately for the industry and role.

• Be punctual for your interview to demonstrate respect for the interviewer’s time.

5. Ask Insightful Questions:

• Prepare thoughtful questions to show your interest in the position and company.

• Inquire about the company’s growth plans, safety procedures, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.