Are you gearing up for an interview for a Machine Lacer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Lacer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

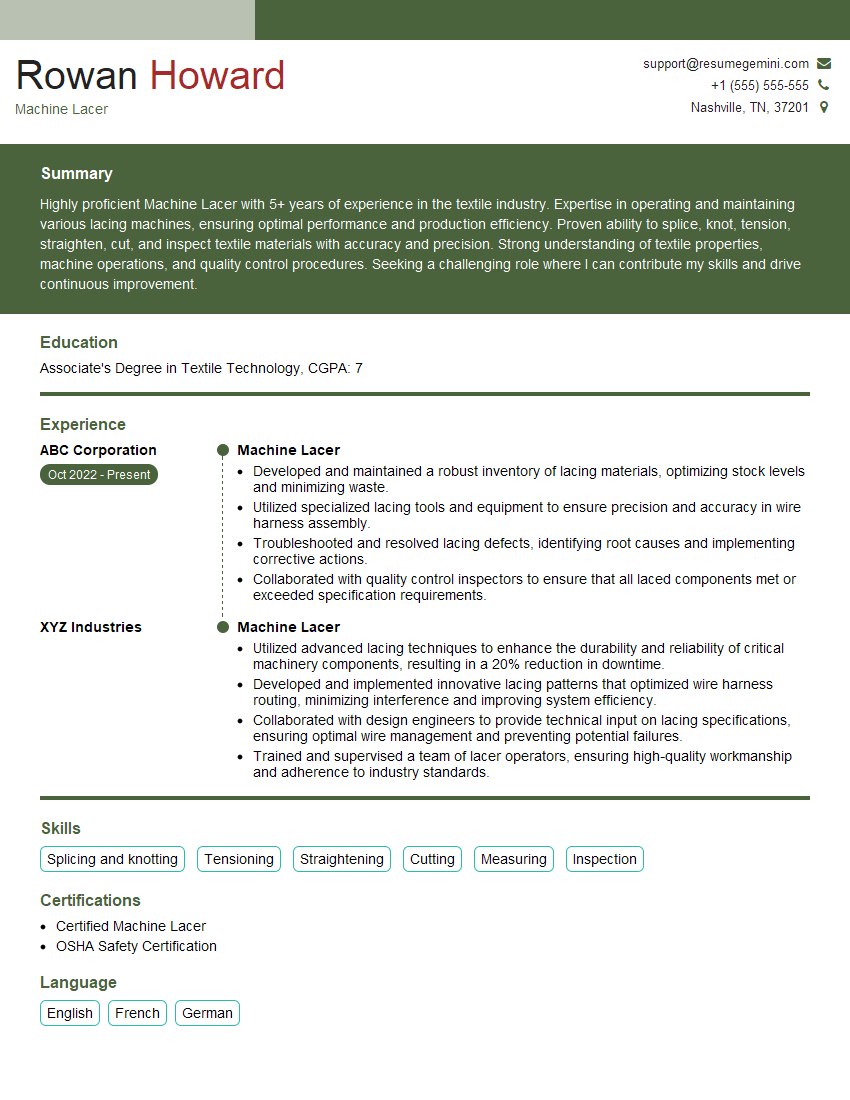

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Lacer

1. Explain the different types of laser cutting machines and their applications?

There are various types of laser cutting machines, each with its own advantages and applications:

- CO2 laser cutters: Use carbon dioxide gas as the laser medium, offering high power and precision. Suitable for cutting non-metals like wood, acrylic, and leather.

- Fiber laser cutters: Utilize a fiber-optic cable as the laser medium, delivering high beam quality and cutting speeds. Ideal for cutting metals such as stainless steel, aluminum, and copper.

- Nd:YAG laser cutters: Employ a neodymium-doped yttrium aluminum garnet (Nd:YAG) crystal as the laser medium. Known for their versatility, they can cut both metals and non-metals, including ceramics and glass.

- Excimer laser cutters: Utilize rare gases like argon or krypton to produce ultraviolet light. Suitable for cutting materials with high absorption in the ultraviolet spectrum, such as polymers and composites.

2. Describe the process of laser cutting, including the factors that affect cut quality?

Factors Affecting Cut Quality

- Laser power: Higher power results in faster cutting speeds and improved edge quality.

- Cutting speed: Optimal speed depends on material thickness and laser power. Too high speed can lead to rough edges.

- Focus: Correct focus is crucial for achieving precise cuts. Misalignment can result in uneven or incomplete cuts.

- Material thickness: Laser cutters have limitations on material thickness, varying depending on machine capabilities.

- Material properties: Different materials require specific laser parameters for best results.

Process Overview

- The laser beam is generated and focused onto the material.

- The laser energy melts or vaporizes the material along the cutting path.

- The molten or vaporized material is blown away by assist gas (e.g., nitrogen or oxygen) to create the cut.

3. Explain the safety precautions and maintenance procedures for laser cutting machines?

Safety Precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Ensure proper ventilation to remove fumes and gases generated during cutting.

- Keep the laser area clean and free of flammable materials.

- Lock out and tag out the machine before performing any maintenance.

- Train operators thoroughly on safe operation procedures.

Maintenance Procedures:

- Regularly check and clean lenses, mirrors, and other optical components.

- Inspect and replace laser tube or fiber as needed.

- Lubricate moving parts according to manufacturer’s recommendations.

- Keep the machine’s software up to date.

- Calibrate the machine periodically to ensure accuracy.

4. Describe the different types of assist gases used in laser cutting and their effects on the cutting process?

Assist gases play a crucial role in laser cutting by:

- Removing molten or vaporized material from the cut

- Cooling the workpiece and reducing heat-affected zones

- Influencing the cutting speed and edge quality

Common assist gases include:

- Nitrogen: Inert gas that provides good cut quality and minimizes oxidation.

- Oxygen: Reactive gas that accelerates cutting speed but can cause oxidation.

- Argon: Inert gas that produces smooth cuts and is often used for non-ferrous metals.

- Helium: Inert gas that provides high cutting speeds and is used for cutting thick materials.

5. Explain the concept of kerf and how it affects the design of laser-cut parts?

Kerf refers to the width of the material removed by the laser cut.

- Kerf size varies depending on laser power, material thickness, cutting speed, and assist gas used.

- It is important to consider kerf when designing parts to ensure proper fit and functionality.

- Designers should adjust part dimensions accordingly to account for the kerf.

- Tolerances and clearances must be carefully considered to prevent interference or loose fits.

6. Describe the different methods for programming laser cutting machines?

- G-code: A standardized numerical control (NC) language used to define cutting paths and machine movements.

- DXF/DWG: CAD file formats that contain the geometry of the parts to be cut.

- Proprietary software: Software provided by machine manufacturers to create cutting programs specifically for their machines.

Some machines may support direct import of 3D CAD models, eliminating the need for manual programming.

7. Discuss the advantages and disadvantages of using laser cutting technology?

Advantages

- High precision and accuracy

- Fast cutting speeds

- Minimal heat-affected zones

- Versatile, can cut a wide range of materials

- Automated process, reducing labor costs

Disadvantages

- Can be expensive

- Requires skilled operators

- Generates fumes and gases that require ventilation

- Limited cutting thickness for some materials

- Safety concerns, such as laser radiation and fire hazards

8. Explain the role of nesting in laser cutting and how it can optimize material usage?

Nesting involves arranging parts within the material sheet to minimize wasted space and maximize material utilization.

- Nesting software algorithms optimize part placement based on shape, size, and orientation.

- Effective nesting can reduce material waste and lower overall production costs.

- It also helps minimize machine downtime for material loading and unloading.

9. Describe the different types of laser cutting applications and industries where it is commonly used?

Laser cutting is used in various industries, including:

- Automotive

- Aerospace

- Electronics

- Medical

- Industrial machinery

- Sign making

- Jewelry

Applications include:

- Cutting precision parts

- Creating intricate designs

- Fabricating prototypes

- Producing medical devices

- Making custom signage

10. What are the emerging trends in laser cutting technology?

- Advanced beam shaping: Techniques like beam steering and wobbling enhance cut quality and efficiency.

- Ultrashort pulse lasers: Enable precision cutting of ultra-thin materials and delicate structures.

- Hybrid laser systems: Combine laser with other technologies like waterjet or plasma cutting for increased versatility.

- Automation and Industry 4.0: Integration with robotics and IoT devices for automated material handling and process monitoring.

- Sustainability: Focus on reducing energy consumption and minimizing waste through optimized nesting and eco-friendly assist gases.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Lacer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Lacer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Lacers are responsible for operating and maintaining machines that lace fabrics together. They ensure that the machines are running smoothly and that the fabrics are laced correctly. Some of the key job responsibilities of a Machine Lacer include:

1. Operating machinery

Machine Lacers are responsible for operating a variety of machines, including lace machines, sewing machines, and knitting machines. They must be able to operate these machines safely and efficiently.

- Understanding the functions and operations of different types of lacing machinery

- Setting up and calibrating machines according to specifications

2. Lacing fabrics

Machine Lacers are responsible for lacing fabrics together. They must be able to lace fabrics accurately and according to specifications.

- Feeding fabrics into machines and ensuring proper alignment

- Adjusting machine settings to achieve optimal lacing results

3. Inspecting fabrics

Machine Lacers are responsible for inspecting fabrics before and after they are laced. They must be able to identify any defects in the fabric.

- Examining fabrics for tears, holes, or other defects

- Identifying and marking any imperfections for further processing

4. Maintaining machinery

Machine Lacers are responsible for maintaining the machines they operate. They must be able to identify and fix any problems with the machines.

- Performing regular maintenance and cleaning of machines

- Identifying and resolving mechanical issues or malfunctions

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and landing the job. Here are some interview tips and hacks to help you ace your Machine Lacer interview:

1. Research the company and the position

Take the time to learn about the company you’re applying to and the specific position you’re interviewing for. This will help you understand the company’s culture, values, and goals, and will allow you to tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry news and articles

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, regardless of the position you’re applying for. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Be prepared to talk about your experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your work history, your skills, and your accomplishments. Use specific examples to illustrate your points.

- Highlight your experience in operating and maintaining lacing machinery

- Provide examples of your ability to lace fabrics accurately and efficiently

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Wear business attire that is clean and pressed

- Arrive at the interview location 10-15 minutes early

5. Be confident and enthusiastic

Confidence is key in any interview. Believe in yourself and your abilities, and let the interviewer know that you’re excited about the opportunity to work for their company.

- Maintain eye contact with the interviewer

- Speak clearly and confidently

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Lacer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Lacer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.