Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Leather Trimmer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

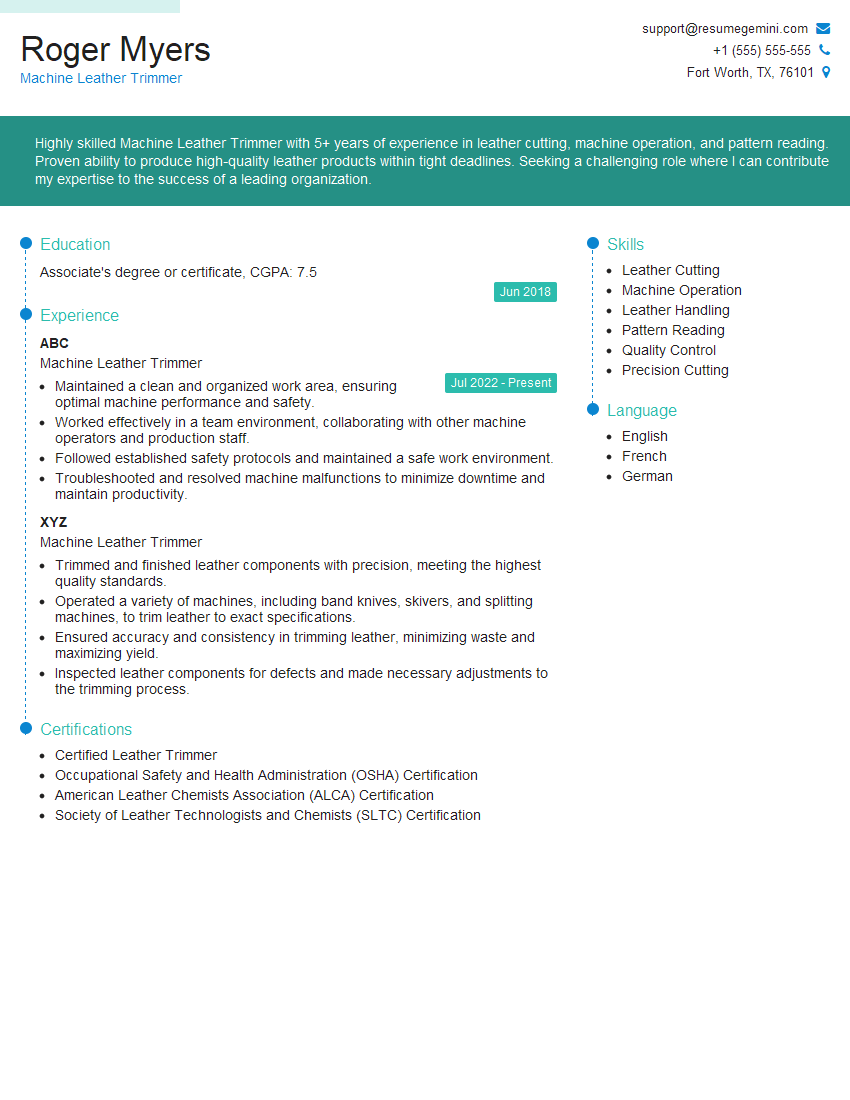

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Leather Trimmer

1. What are the different types of leather trimming machines and their uses?

There are various types of leather trimming machines, each designed for specific tasks.

- Band knife trimming machines: These machines use a continuous loop of blade to cut leather precisely and efficiently. They are commonly used for cutting straight edges and curves in leather goods.

- Die-cutting machines: These machines use shaped dies to cut leather into intricate shapes and patterns. They are suitable for mass production of leather components, such as bags, wallets, and shoes.

- Skiving machines: These machines are used to thin the edges of leather, creating a smooth and even surface. They are essential for preparing leather for sewing and assembly.

- Edge trimmers: These machines trim the edges of leather pieces to create a clean and finished look. They can be used to remove excess leather, bevel edges, or create decorative patterns.

2. How do you ensure the accuracy and quality of your leather trimming?

Precision Equipment

- Using well-calibrated and maintained trimming machines.

- Employing sharp and high-quality cutting tools.

Attention to Detail

- Carefully inspecting leather pieces before and after trimming.

- Following precise measurements and templates to ensure accurate cuts.

Quality Control

- Implementing regular quality checks to identify and correct any errors.

- Using measuring tools and gauges to ensure consistency in dimensions.

3. What are some common challenges you encounter in leather trimming and how do you overcome them?

Leather trimming presents several challenges that require careful attention and problem-solving skills.

- Variations in leather thickness: Using adjustable machine settings and selecting the appropriate cutting tools to accommodate different leather thicknesses.

- Difficult cuts: Employing specialized cutting techniques, such as skiving or die-cutting, to handle intricate or complex cuts.

- Precision trimming: Using precise measurements, templates, and sharp tools to ensure accurate and consistent cuts.

- Edge quality: Paying attention to the type of edge desired (beveled, rounded, etc.) and using appropriate trimming techniques to achieve the desired finish.

4. What is the importance of using sharp cutting tools in leather trimming?

Sharp cutting tools are crucial in leather trimming for several reasons:

- Precision: Sharp tools make clean and precise cuts, reducing the risk of ragged edges or uneven surfaces.

- Efficiency: Sharp tools cut through leather more easily, increasing productivity and reducing the amount of force required.

- Edge quality: Sharp tools create smooth and polished edges, enhancing the overall appearance of the leather piece.

- Tool longevity: Sharp tools maintain their edge for longer periods, reducing the need for frequent sharpening and replacement.

5. Describe the process of skiving leather and its importance in leathercraft.

Skiving involves thinning the edges of leather to achieve a smooth and gradual transition between different thicknesses.

- Preparation: Mark the areas to be skived and select the appropriate skiving tool.

- Skiving: Hold the leather firmly and carefully pass it through the skiving tool, gradually reducing its thickness.

- Finishing: Smooth out the skived edges using sandpaper or a burnishing tool.

Skiving is crucial for:

- Seaming: Thinning the edges allows for seamless and durable stitching.

- Edge finishing: Skiving creates a smooth surface for applying edge paints or finishes.

- Detailing: It enhances the aesthetics of leather pieces by creating intricate shapes and designs.

6. What are the safety precautions you observe when operating leather trimming machines?

- Guarding: Ensuring that all moving parts and blades are adequately guarded to prevent accidental contact.

- Personal Protective Equipment (PPE): Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Machine maintenance: Regularly inspecting and maintaining machines to ensure they are in good working condition.

- Proper posture: Maintaining good posture while operating machines to avoid strain or injury.

- Electrical safety: Checking electrical connections and grounding to prevent electrical hazards.

7. How do you handle leather scraps and waste generated during trimming?

- Sorting: Separating leather scraps based on size, thickness, and quality.

- Recycling: Recycling suitable leather scraps into new products, such as smaller leather goods or upholstery.

- Disposal: Properly disposing of non-recyclable scraps in an environmentally responsible manner.

8. What is the role of templates in leather trimming and how do you ensure their accuracy?

Templates are essential for ensuring precision and consistency in leather trimming.

- Accuracy: Templates provide accurate outlines and dimensions for cutting leather pieces.

- Efficiency: Templates speed up the trimming process by eliminating the need for manual measurements and marking.

- Repeatability: Templates allow for the production of multiple identical pieces, maintaining uniformity in design.

To ensure accuracy:

- Using durable and dimensionally stable materials for templates.

- Carefully checking measurements and aligning templates precisely before cutting.

- Regularly inspecting templates for wear or damage.

9. How do you stay updated with the latest advancements in leather trimming technology?

- Industry events: Attending trade shows and conferences to learn about new equipment and techniques.

- Trade publications: Reading industry magazines and journals to stay informed about technological advancements.

- Online resources: Exploring reputable websites, forums, and blogs dedicated to leather trimming.

- Manufacturer training: Participating in workshops and training programs offered by equipment manufacturers.

10. What are your strengths and weaknesses as a Machine Leather Trimmer?

Strengths

- Precision and Accuracy: Proven ability to perform precise cuts and achieve high levels of accuracy.

- Attention to Detail: Meticulous in inspecting and handling leather to ensure quality.

- Technical Proficiency: Familiarity with various leather trimming machines and techniques.

- Problem-Solving Skills: Able to identify and resolve trimming challenges effectively.

Weaknesses

- Experience with Specialized Leathers: Limited experience in trimming exotic or particularly delicate leathers.

- Speed: Acknowledging potential for improvement in trimming speed while maintaining accuracy.

I am committed to continuous improvement and eager to address my weaknesses through further training and experience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Leather Trimmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Leather Trimmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Leather Trimmers are responsible for trimming and finishing leather goods. They use a variety of machines to cut, shape, and polish leather. Their duties may also include inspecting the finished product for quality control. Here are some of the key job responsibilities of a Machine Leather Trimmer:

1. Trimming and finishing leather goods

Machine Leather Trimmers use a variety of machines to trim and finish leather goods. This may include cutting out shapes, beveling edges, and polishing the surface of the leather. They must be able to operate these machines safely and efficiently.

2. Inspecting the finished product

Machine Leather Trimmers are responsible for inspecting the finished product for quality control. They must be able to identify and correct any defects in the leather. They may also be responsible for packaging and shipping the finished product.

3. Maintaining the machines

Machine Leather Trimmers are responsible for maintaining the machines they use. This may include cleaning, oiling, and adjusting the machines. They must be able to troubleshoot and repair any problems that may occur.

4. Working with other team members

Machine Leather Trimmers may work with other team members, such as leather cutters and sewers. They must be able to communicate effectively with their team members and work together to produce high-quality products.

Interview Tips

Preparing for an interview can be a daunting task, but there are some things you can do to increase your chances of success. Here are a few interview tips for Machine Leather Trimmers:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website or in industry publications.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Bring a portfolio of your work

If you have any examples of your work, bring them to your interview. This will give the interviewer a chance to see your skills and abilities firsthand. You can include examples of your work in a portfolio or on a website.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual attire. You should also arrive on time for your interview and be prepared to answer questions about your experience and qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Leather Trimmer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!