Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Long Goods Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

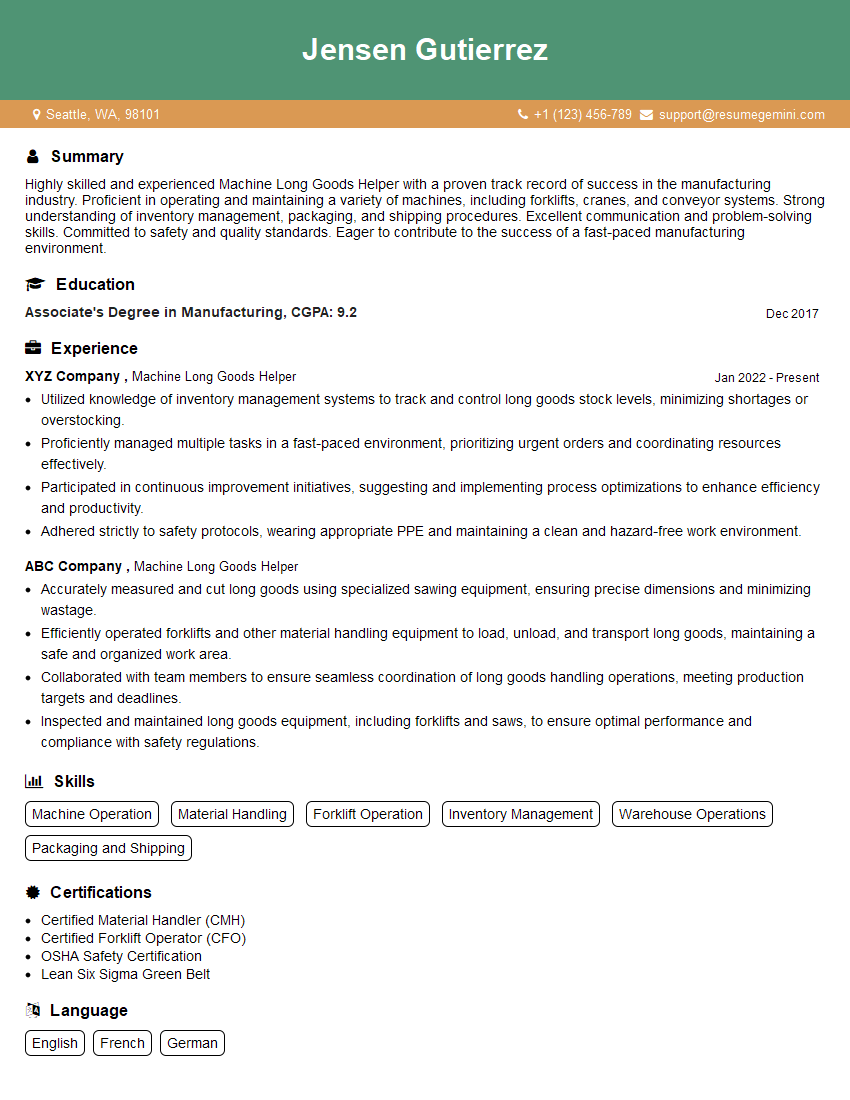

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Long Goods Helper

1. What are the key responsibilities of a Machine Long Goods Helper?

As a Machine Long Goods Helper, my key responsibilities would include:

- Assisting with the operation of the long goods machine to produce high-quality products

- Monitoring the machine for any irregularities or malfunctions and reporting them to the supervisor

- Loading and unloading materials onto the machine, ensuring they are aligned properly for optimal cutting

- Inspecting the finished products to ensure they meet specifications and quality standards

- Maintaining a clean and organized work area, adhering to safety protocols and regulations

2. What specific skills and experience do you have that make you qualified for this role?

I possess a combination of technical skills and relevant experience that make me well-suited for the Machine Long Goods Helper role:

Technical Skills:

- Proficient in operating long goods machines and handling various types of materials

- Experience in maintaining and troubleshooting machinery, ensuring optimal performance

- Knowledge of quality control procedures and specifications for long goods production

Relevant Experience:

- Previously employed as a Machine Long Goods Helper for [Company Name], where I gained hands-on experience in operating the machine and maintaining high production standards

- Experience in a manufacturing environment, demonstrating proficiency in material handling and quality control techniques

3. How do you ensure the accuracy and precision of the long goods cutting process?

To ensure accuracy and precision, I follow these steps:

- Prior to cutting, I carefully review the cutting specifications and ensure that the machine is set up correctly

- I use precise measuring tools to align the materials on the machine bed, ensuring they are positioned accurately for cutting

- During the cutting process, I monitor the machine’s performance to identify any deviations from the specified cutting parameters

- I regularly inspect the finished products and compare them to the specifications to verify their accuracy and precision

4. How do you prioritize and manage multiple tasks in a fast-paced production environment?

In a fast-paced production environment, I prioritize and manage multiple tasks effectively through these practices:

- I start by assessing the urgency and importance of each task and allocate my time accordingly

- I break down complex tasks into smaller, manageable steps to streamline the workload

- I utilize available resources, such as other team members or tools, to delegate tasks and improve efficiency

- I maintain clear communication with my supervisor and colleagues to ensure seamless coordination and avoid duplication of effort

5. What safety precautions do you take when operating the long goods machine?

When operating the long goods machine, I prioritize safety by adhering to the following precautions:

- I wear appropriate safety gear, including gloves, safety glasses, and earplugs, to protect myself from potential hazards

- Before starting the machine, I conduct a thorough safety inspection to ensure that all guards and safety features are in place and functioning properly

- I maintain a safe work area, free of clutter and tripping hazards

- I remain vigilant and focused during operation, paying attention to any unusual sounds or vibrations

- In the event of an emergency, I am trained to follow established safety protocols and immediately report any incidents to my supervisor

6. How do you handle and resolve common operational issues that may arise with the long goods machine?

To handle and resolve common operational issues with the long goods machine, I follow these steps:

- I quickly identify the issue and assess its potential impact on production

- I consult the machine’s manual or maintenance logs to determine the appropriate troubleshooting procedures

- I systematically isolate the issue and conduct necessary adjustments or repairs using appropriate tools and techniques

- After resolving the issue, I test the machine to ensure it is operating correctly and meets production requirements

- I document the issue and resolution in a maintenance log for future reference and to identify potential patterns or trends

7. How do you maintain and clean the long goods machine to ensure optimal performance and longevity?

To maintain and clean the long goods machine for optimal performance and longevity, I implement the following practices:

- I regularly clean the machine’s exterior and interior surfaces to remove any debris, dust, or contaminants

- I lubricate moving parts according to the manufacturer’s guidelines to reduce friction and wear

- I inspect the machine’s components, such as belts, bearings, and cutting tools, for signs of wear or damage and replace or repair them as needed

- I follow the manufacturer’s recommended maintenance schedule for more comprehensive servicing and calibration

- I keep a detailed maintenance log to track cleaning, lubrication, and repairs performed on the machine

8. How do you ensure that the finished long goods products meet the required quality standards?

To ensure that the finished long goods products meet the required quality standards, I employ the following measures:

- I inspect the raw materials before they are loaded onto the machine to identify any defects or inconsistencies

- I monitor the cutting process closely to ensure that the products are being cut to the correct specifications

- I perform regular quality checks on the finished products using measuring tools and visual inspections

- I set up quality control checkpoints throughout the production process to identify and address any potential issues early on

- I maintain detailed records of quality checks and any corrective actions taken to ensure traceability and continuous improvement

9. How do you stay up-to-date with the latest industry trends and advancements in long goods production?

To stay up-to-date with the latest industry trends and advancements in long goods production, I engage in ongoing learning and development activities:

- I attend industry conferences and webinars to connect with experts and gain insights into emerging technologies and best practices

- I read trade publications and technical journals to stay informed about new developments and innovations in the field

- I participate in online forums and discussion groups to exchange knowledge with other professionals and stay abreast of industry news

- I actively seek out training opportunities provided by my company or external organizations to enhance my skills and knowledge

10. How do you handle working in a fast-paced, continuous production environment?

To effectively handle working in a fast-paced, continuous production environment, I employ the following strategies:

- I maintain a strong work ethic and a positive attitude, even under pressure

- I prioritize tasks effectively and manage my time wisely to meet production targets

- I work efficiently and maintain a steady pace throughout my shift

- I actively communicate with my team members to coordinate our efforts and ensure smooth production flow

- I am proactive in identifying and addressing potential bottlenecks or delays to minimize disruptions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Long Goods Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Long Goods Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Long Goods Helpers are responsible for supporting the safe and efficient operation of metalworking machinery. Their duties include operating equipment, monitoring production, and assisting with maintenance and repairs. They work closely with other members of the production team to ensure that products meet quality standards and deadlines are met.

1. Operation of Metalworking Machinery

Machine Long Goods Helpers are responsible for the safe and efficient operation of a variety of metalworking machinery, including lathes, mills, grinders, and saws. They must be able to read and interpret blueprints and technical drawings, and set up and operate machines according to specifications.

- Operate lathes, mills, grinders, and saws

- Read and interpret blueprints and technical drawings

- Set up and operate machines according to specifications

2. Production Monitoring

Machine Long Goods Helpers are responsible for monitoring production and ensuring that products meet quality standards. They must be able to identify defects and take corrective action, and they must be able to work independently and as part of a team.

- Monitor production and ensure that products meet quality standards

- Identify defects and take corrective action

- Work independently and as part of a team

3. Maintenance and Repairs

Machine Long Goods Helpers are responsible for assisting with the maintenance and repair of metalworking machinery. They must be able to identify common problems and perform basic repairs, and they must be able to work safely around machinery.

- Assist with the maintenance and repair of metalworking machinery

- Identify common problems and perform basic repairs

- Work safely around machinery

4. Other Duties

Machine Long Goods Helpers may also be responsible for performing other duties, such as:

- Cleaning and maintaining work areas

- Loading and unloading materials

- Assisting with inventory control

Interview Tips

If you are preparing for an interview for a Machine Long Goods Helper position, there are a few things you can do to improve your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you prepare for the specific questions that you may be asked.

- Visit the company’s website

- Read the job description carefully

- Look for news articles and other information about the company

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in interviews for Machine Long Goods Helper positions. By practicing answering these questions ahead of time, you can increase your confidence and improve your chances of giving a good impression.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with metalworking machinery?

- How do you handle working under pressure?

3. Be Prepared to Talk About Your Skills and Experience

In addition to answering the common interview questions, you should also be prepared to talk about your skills and experience. This is your chance to sell yourself to the interviewer and show why you are the best candidate for the job.

- Highlight your experience with metalworking machinery

- Describe your skills in operating, monitoring, and maintaining machinery

- Emphasize your teamwork and problem-solving skills

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late can reflect poorly on your character.

- Dress in business casual attire

- Arrive on time for your interview

- Be polite and respectful to everyone you meet

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Long Goods Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Long Goods Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.