Are you gearing up for a career in Machine Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

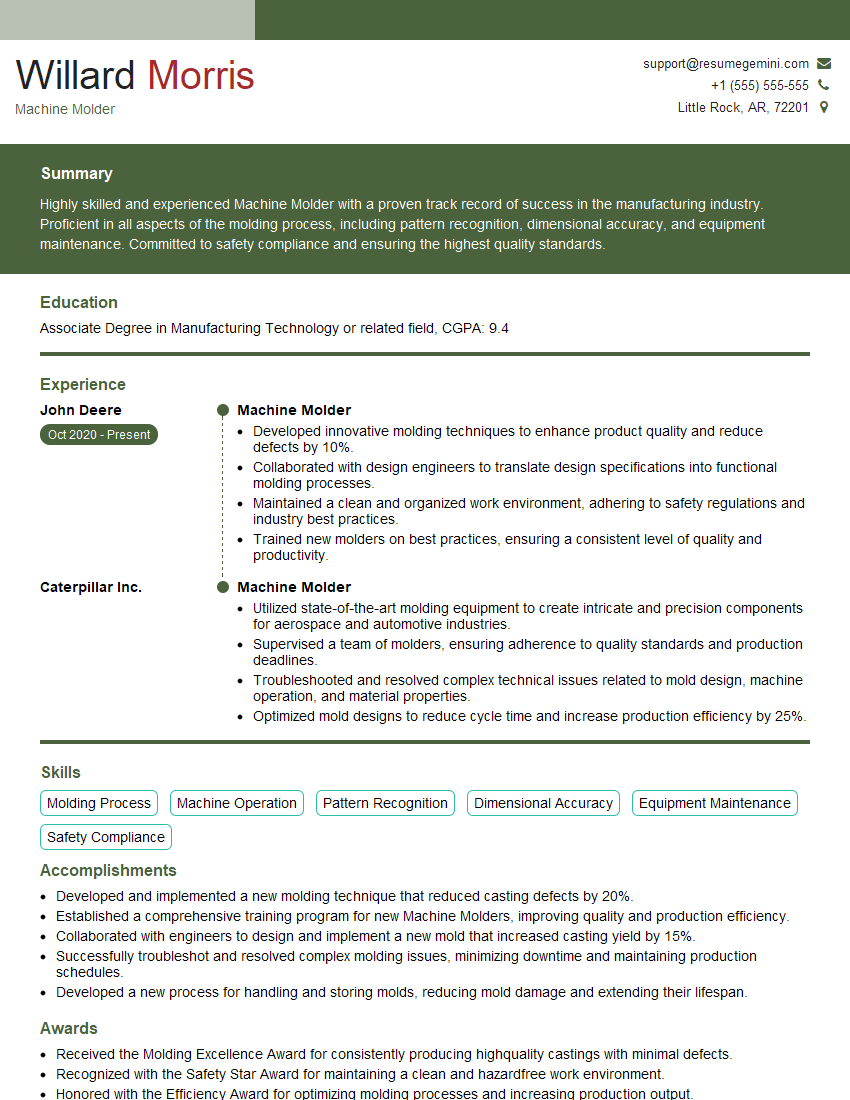

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Molder

1. What are the different types of molding machines and their applications?

- Types of molding machines:

- Roll molding machines: Used to mold simple shapes such as cylinders and tubes

- Extrusion molding machines: Used to mold continuous shapes such as pipes and wires

- Injection molding machines: Used to mold complex shapes by injecting molten plastic into a mold

- Compression molding machines: Used to mold rubber and plastic by applying heat and pressure

- Applications of molding machines:

- Automotive industry: Molding of car parts such as bumpers, dashboards, and interior trim

- Medical industry: Molding of medical devices such as catheters, syringes, and implants

- Electronics industry: Molding of electronic components such as circuit boards and connectors

- Construction industry: Molding of building materials such as pipes, siding, and roofing

2. What are the key parameters to consider when selecting a molding machine?

Factors to consider:

- Type of material to be molded

- Size and complexity of the molded part

- Required production rate

- Available budget

- Technical specifications such as clamping force, injection pressure, and mold size

Additional considerations:

- Reputation and reliability of the machine manufacturer

- Availability of technical support and spare parts

- Energy efficiency and environmental impact of the machine

3. Describe the process of setting up and operating a molding machine.

- Machine setup:

- Installing the mold

- Setting the machine parameters (e.g., temperature, pressure, cycle time)

- Feeding the material into the machine

- Machine operation:

- Starting the cycle

- Monitoring the process (e.g., temperature, pressure)

- Removing the molded part from the machine

4. What are common defects in molded parts and how can they be prevented?

Types of defects:

- Dimensional errors (e.g., incorrect size or shape)

- Surface defects (e.g., cracks, voids, or discoloration)

- Material defects (e.g., weak or brittle material)

Prevention methods:

- Using high-quality materials and molds

- Optimizing machine settings and process parameters

- Regular maintenance and calibration of the machine

- Implementing quality control measures during the molding process

5. What is the role of quality control in the molding process?

- Ensuring that molded parts meet the required specifications

- Identifying and eliminating defects through inspections and testing

- Developing and implementing quality control measures (e.g., inspection plans, process audits)

- Maintaining records and documentation of quality control activities

- Working with production staff to improve the molding process and reduce defects

6. What are the safety precautions that should be followed when operating a molding machine?

- Wearing appropriate personal protective equipment (e.g., gloves, safety glasses, earplugs)

- Keeping the work area clean and free of hazards

- Following established safety protocols and procedures

- Being aware of the location of emergency stops and other safety features

- Receiving proper training and authorization before operating the machine

7. What are some common maintenance tasks for a molding machine?

- Regular cleaning and lubrication of the machine

- Inspection and replacement of worn or damaged parts

- Calibration of sensors and controls

- Checking and adjusting fluid levels (e.g., hydraulic fluid, coolant)

- Performing software updates and upgrades

8. How can you troubleshoot common problems that occur during the molding process?

- Identifying the problem (e.g., defective parts, machine malfunction)

- Checking the machine settings and parameters

- Inspecting the mold and material

- Consulting with manufacturers or technical experts

- Implementing corrective actions (e.g., adjusting settings, replacing parts)

9. What is your experience with different types of molding materials?

- List of materials worked with and their properties

- Experience in handling, processing, and troubleshooting different materials

- Knowledge of the specific characteristics of each material and how they affect the molding process

10. How do you stay updated with the latest advancements in molding technology?

- Reading industry publications and attending conferences

- Participating in training programs and workshops

- Networking with other professionals in the field

- Staying informed about new materials and equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Molders are responsible for operating and maintaining molding machines to produce a variety of metal castings. They work with patterns, molds, and other tools to create intricate shapes and designs in metal. Key job responsibilities include:

1. Operating and Maintaining Molding Machines

Machine Molders operate and maintain molding machines, ensuring that they are running smoothly and efficiently. They inspect machines regularly, perform routine maintenance, and troubleshoot any problems that may arise.

- Set up and operate molding machines to create molds and cast metal objects.

- Monitor machines during operation, making adjustments as needed.

- Troubleshoot and repair molding machines to ensure optimal performance.

2. Working with Patterns and Molds

Machine Molders work with patterns and molds to create intricate shapes and designs in metal. They use a variety of tools and techniques to create molds and cast metal objects.

- Inspect patterns and molds to ensure accuracy and quality.

- Prepare molds using sand, plaster, or other materials to create the desired shape.

- Cast molten metal into molds to create metal objects.

3. Finishing and Inspecting Castings

Machine Molders finish and inspect castings to ensure that they meet specifications. They clean and smooth castings, removing any imperfections or burrs. They also inspect castings for defects and ensure that they meet customer requirements.

- Remove castings from molds and clean them to remove any excess material.

- Inspect castings for defects and make any necessary repairs or adjustments.

- Ensure that finished castings meet customer specifications and quality standards.

4. Quality Control and Safety

Machine Molders are responsible for maintaining quality control and safety in the workplace. They follow established procedures to ensure that castings are produced to specifications and that the work environment is safe.

- Follow established quality control procedures to ensure that castings meet specifications.

- Wear appropriate personal protective equipment (PPE) and follow safety protocols.

- Report any accidents or near misses to management.

Interview Tips

To ace an interview for a Machine Molder position, it is important to be well-prepared and to demonstrate your skills and experience. Here are some tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

- Visit the company website to learn more about their history, products, and services.

- Read online reviews of the company to get an idea of the work environment and culture.

- Review the job description carefully to identify the key skills and experience required for the position.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver clear and concise answers.

- Prepare a brief introduction that highlights your skills and experience as a Machine Molder.

- Identify your key strengths and weaknesses, and be prepared to discuss them in detail.

- Research the company and the industry to identify the challenges and opportunities facing the company.

3. Demonstrate Your Skills and Experience

During the interview, be sure to demonstrate your skills and experience as a Machine Molder. Use specific examples to illustrate your abilities and how you have used them to succeed in previous roles.

- Describe your experience operating and maintaining molding machines.

- Provide examples of your work with patterns and molds, and how you have created intricate shapes and designs in metal.

- Discuss your experience finishing and inspecting castings, and how you have ensured that they meet customer specifications.

4. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview is a great way to show your interest in the position and the company. It also gives you a chance to learn more about the company and the role. Prepare a few thoughtful questions in advance, such as:

- What are the company’s goals for the next year?

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!