Are you gearing up for an interview for a Machine Operator Hop Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Operator Hop Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

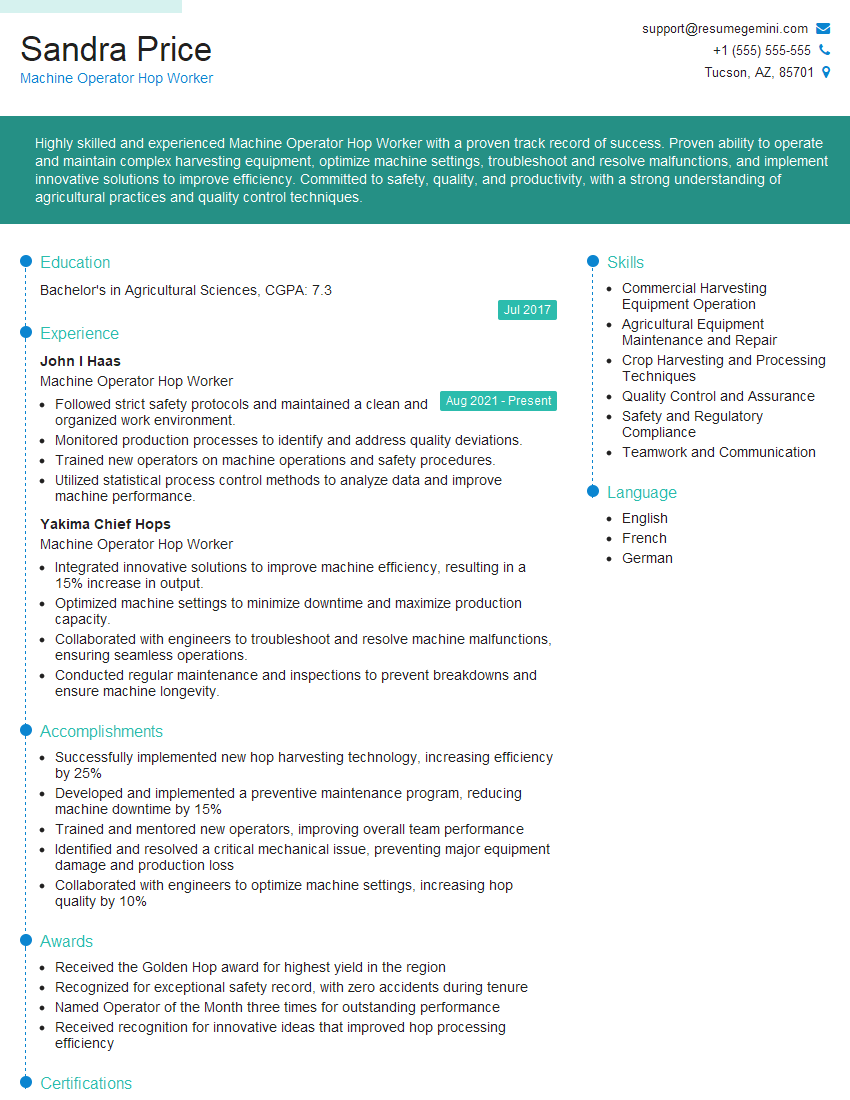

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Operator Hop Worker

1. Explain the primary responsibilities of a Machine Operator Hop Worker?

As a Machine Operator Hop Worker, my key responsibilities involve operating and maintaining specialized machinery used in hop production. My duties typically include:

- Operating picking, drying, and baling equipment to harvest, process, and package hops

- Monitoring machine settings and adjusting them as needed to ensure optimal performance

- Conducting routine maintenance on machinery, including cleaning, lubrication, and minor repairs

- Ensuring that all safety protocols are followed during operation

- Collaborating with other team members to ensure smooth and efficient production

2. Describe the different types of hop picking machines and their advantages and disadvantages?

Types of Hop Picking Machines:

- Mechanical Harvesters:

- Advantages: High efficiency, low labor requirements

- Disadvantages: Can damage hops, higher maintenance costs

- Overhead Harvesters:

- Advantages: Gentle on hops, suitable for small farms

- Disadvantages: Lower efficiency, higher labor requirements

- Air Harvesters:

- Advantages: Non-invasive, can hover over crops

- Disadvantages: Can be affected by weather conditions, more expensive

3. How do you calibrate and maintain the moisture content of hops during the drying process?

Calibrating and maintaining the moisture content of hops during drying is crucial to ensure optimal quality. I follow these steps:

- Calibration: Using a moisture meter, I determine the initial moisture content of the hops.

- Drying: I set the dryer temperature and airflow according to the desired moisture level.

- Monitoring: I monitor the moisture content throughout the drying process using a probe or other measuring device.

- Adjustments: If the moisture content deviates from the target, I adjust the dryer settings accordingly.

- Maintenance: I regularly clean and maintain the dryer to ensure efficient operation.

4. Describe the techniques you use to minimize hop waste during the harvesting and processing stages?

Minimizing hop waste is essential for maximizing yield and profitability. I employ the following techniques:

- Careful Harvesting: I operate picking machines with precision to avoid damaging hops.

- Proper Drying: I dry hops at the optimal temperature and airflow to prevent over-drying and moisture loss.

- Efficient Baling: I use specialized balers to minimize compaction and preserve hop quality.

- Storage Optimization: I store hops in well-ventilated areas with controlled temperature and humidity to prevent spoilage.

- Waste Management: I collect and recycle hop waste, such as stems and leaves, for compost or other uses.

5. How do you ensure the safety of yourself and others while operating hop processing machinery?

Safety is paramount in hop processing operations. I adhere to these practices to ensure a safe work environment:

- PPE Compliance: I wear appropriate personal protective equipment, including gloves, earplugs, and a safety mask.

- Machine Safety: I inspect machinery regularly and follow all safety protocols, including lockout/tagout procedures.

- Awareness of Surroundings: I maintain situational awareness and communicate with colleagues to prevent accidents.

- Emergency Preparedness: I am trained in emergency response procedures and know the location of safety equipment.

- Collaboration and Communication: I work with team members to identify and address potential hazards.

6. Describe the quality control procedures you follow to ensure the quality of processed hops?

Maintaining the quality of processed hops is crucial. I follow these quality control measures:

- Raw Material Inspection: I inspect incoming hops for quality, aroma, and physical characteristics.

- Processing Monitoring: I monitor all stages of processing, including drying and baling, to ensure adherence to quality standards.

- Sampling and Testing: I collect samples throughout the process for moisture content, alpha acid content, and other quality tests.

- Documentation: I maintain detailed records of quality control checks and any corrective actions taken.

- Continuous Improvement: I participate in quality improvement initiatives to identify areas for optimization.

7. How do you handle and resolve production issues that may arise during hop processing?

Production issues are inevitable, and I handle them efficiently to minimize downtime and maintain quality:

- Identification and Analysis: I quickly identify and assess the root cause of the issue.

- Solution Development: I collaborate with fellow operators, supervisors, and engineers to develop effective solutions.

- Implementation and Monitoring: I implement the solution and monitor its impact to ensure the issue is resolved.

- Continuous Learning: I document the issue, solution, and lessons learned to prevent recurrence.

- Communication: I keep management and team members informed of production issues and progress towards resolution.

8. How do you stay up-to-date on the latest advancements in hop processing technology and best practices?

Continuously improving my knowledge is essential to optimize operations. I stay up-to-date through:

- Industry Events: I attend conferences and workshops to learn about new technologies and best practices.

- Trade Publications: I read industry magazines and journals to stay informed about trends and developments.

- Online Resources: I utilize online platforms and databases to access research and technical information.

- Collaboration: I connect with other professionals in the field to share knowledge and ideas.

- Continuing Education: I pursue additional training and certifications to enhance my skills and expertise.

9. Describe your experience in troubleshooting and repairing hop processing equipment?

Equipment malfunctions can occur, and I am proficient in troubleshooting and repairs:

- Problem Identification: I quickly identify the problem and isolate the affected component.

- Resource Utilization: I utilize technical manuals, schematics, and experience to guide my troubleshooting.

- Repair Execution: I perform necessary repairs, including electrical, mechanical, and software adjustments.

- Safety Precautions: I prioritize safety by following proper lockout/tagout procedures and using appropriate tools.

- Testing and Validation: I thoroughly test repaired equipment to ensure functionality and compliance with safety standards.

10. Why are you interested in working as a Machine Operator Hop Worker for our company?

I am eager to join your company as a Machine Operator Hop Worker because:

- Industry Reputation: Your company is recognized for its commitment to quality and innovation in hop processing.

- Growth Opportunities: I believe your company provides opportunities for career growth and professional development.

- Team Culture: I value teamwork and collaboration, which I believe is evident in your company’s culture.

- Sustainability Focus: I am impressed by your company’s focus on sustainability and minimizing environmental impact.

- Location Convenience: The location of your facility is convenient for my residence and daily commute.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Operator Hop Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Operator Hop Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Operator Hop Workers are skilled individuals responsible for operating hop processing machinery in agricultural settings. Their primary responsibilities include:

1. Machine Operation

Operate and maintain hop harvesting, drying, baling, and packaging machinery.

- Ensure smooth functioning of machines, identifying and resolving operational issues promptly.

- Conduct routine maintenance, lubrication, and cleaning of equipment.

2. Quality Control

Monitor the quality of hops throughout the processing operation.

- Inspect hops for contamination, defects, or damage.

- Adhere to established quality standards and procedures.

3. Production Management

Assist in managing hop production processes, including scheduling, output monitoring, and inventory control.

- Monitor crop yields and adjust machine settings accordingly.

- Coordinate with other team members to ensure efficient workflow.

4. Health and Safety

Uphold strict health and safety protocols in accordance with industry regulations.

- Maintain a clean and sanitary work environment.

- Follow proper handling procedures for chemicals and hazardous materials.

- Wear appropriate safety gear and adhere to safety guidelines.

Interview Tips

To excel in an interview for a Machine Operator Hop Worker position, candidates should focus on the following key areas:

1. Technical Knowledge

Demonstrate a thorough understanding of hop processing machinery, including their operation, maintenance, and troubleshooting techniques.

- Highlight previous experience with similar equipment or related industry knowledge.

- Explain how you identify and resolve common machine malfunctions.

2. Quality Assurance

Emphasize your commitment to maintaining high quality standards in hop processing.

- Provide examples of how you have implemented quality control measures in previous roles.

- Discuss your knowledge of industry regulations and quality standards.

3. Teamwork and Communication

Convey your ability to work effectively as part of a team and communicate clearly with colleagues.

- Share experiences where you successfully collaborated with others to achieve shared goals.

- Explain how you handle conflicts or challenges within a team setting.

4. Health and Safety

Demonstrate your understanding of health and safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience in adhering to industry regulations and safety guidelines.

- Provide examples of how you prioritize safety in your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Operator Hop Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.