Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Packer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Packer so you can tailor your answers to impress potential employers.

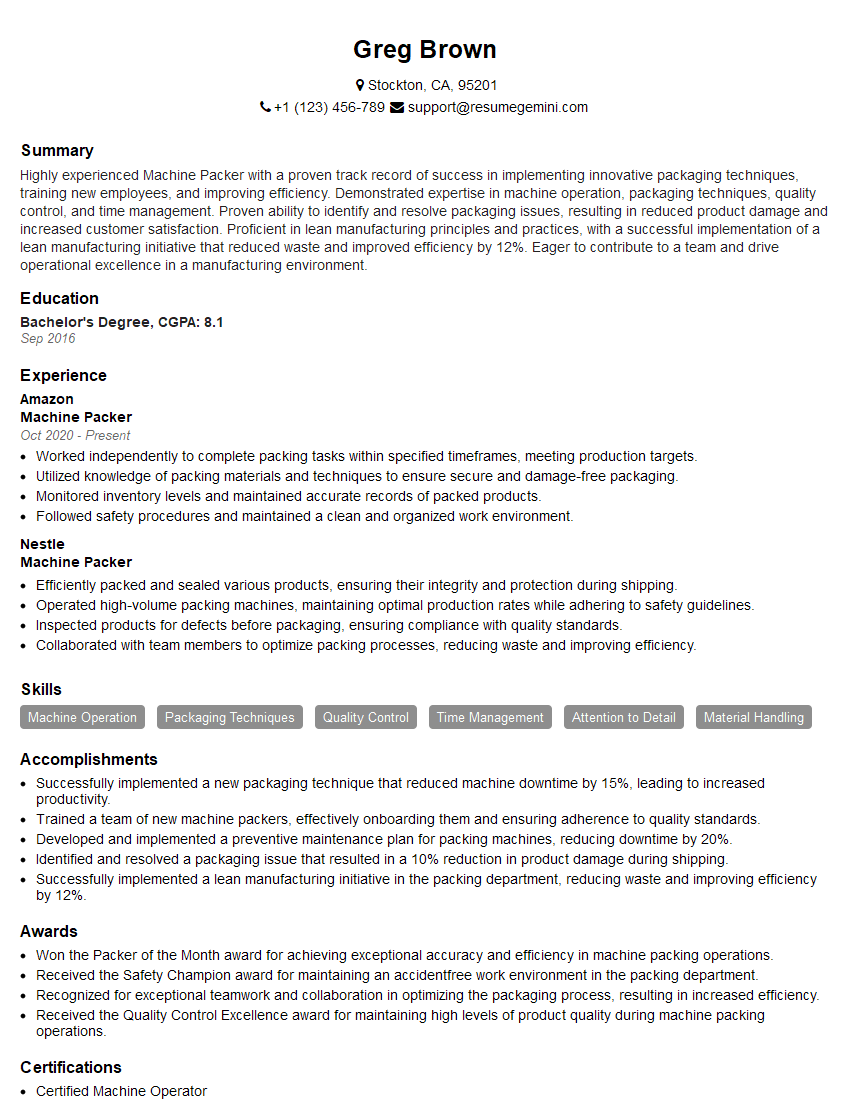

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Packer

1. What are the different types of packaging machines?

- Vertical Form Fill and Seal (VFFS) machines: These machines are used to package products in vertical bags, such as coffee bags, snack bags, and pet food bags.

- Horizontal Form Fill and Seal (HFFS) machines: These machines are used to package products in horizontal bags, such as bread bags, candy bags, and cereal bags.

- Cartoning machines: These machines are used to package products in cartons, such as milk cartons, juice cartons, and yogurt cartons.

- Case packing machines: These machines are used to pack individual products into cases, such as cases of soda cans, cases of bottled water, and cases of canned goods.

- Palletizing machines: These machines are used to stack cases of products onto pallets for shipping.

2. What are the different types of packaging materials?

Paper and paperboard

- Corrugated cardboard

- Solid fibreboard

- Folding carton board

- Kraft paper

- Newsprint

Plastic

- Polyethylene

- Polypropylene

- Polystyrene

- Polyethylene terephthalate

- Polyvinyl chloride

Metal

- Aluminum

- Steel

- Tin

Glass

3. What are the key factors to consider when choosing a packaging machine?

- The type of product being packaged

- The desired production speed

- The available budget

- The space available for the machine

- The level of automation required

4. What are the most common problems that occur with packaging machines and how can they be prevented?

- Mechanical problems: These problems can be caused by a variety of factors, such as wear and tear, improper maintenance, and operator error. They can be prevented by following the manufacturer’s recommended maintenance schedule, using the machine properly, and training operators on how to use the machine safely.

- Electrical problems: These problems can be caused by a variety of factors, such as power surges, loose connections, and faulty wiring. They can be prevented by using surge protectors, making sure that all connections are tight, and inspecting the wiring regularly.

- Pneumatic problems: These problems can be caused by a variety of factors, such as leaks, clogged filters, and faulty valves. They can be prevented by inspecting the pneumatic system regularly, replacing filters as needed, and repairing any leaks promptly.

5. What are the safety precautions that must be observed when operating a packaging machine?

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Keep hands and other body parts away from moving parts.

- Never reach into a machine while it is running.

- Be aware of the location of emergency stop buttons and know how to use them.

- Follow all manufacturer’s instructions for safe operation.

6. How do you maintain a packaging machine?

- Clean the machine regularly to remove dust, dirt, and debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for signs of wear and tear.

- Replace worn parts promptly.

- Follow all manufacturer’s instructions for maintenance.

7. What are the different types of packaging inspections?

- Visual inspection: This is the most common type of packaging inspection. It involves looking at the packaging for defects, such as tears, holes, and dents.

- Dimensional inspection: This type of inspection involves measuring the dimensions of the packaging to make sure that it meets the specifications.

- Weight inspection: This type of inspection involves weighing the packaging to make sure that it contains the correct amount of product.

- Leak inspection: This type of inspection involves checking the packaging for leaks.

8. What are the different types of packaging testing?

- Compression testing: This type of testing involves applying pressure to the packaging to see how much it can withstand.

- Drop testing: This type of testing involves dropping the packaging from a height to see how much it can withstand.

- Vibration testing: This type of testing involves vibrating the packaging to see how much it can withstand.

- Environmental testing: This type of testing involves exposing the packaging to different environmental conditions, such as heat, cold, and humidity.

9. What are the different types of packaging regulations?

- Food and Drug Administration (FDA) regulations: These regulations apply to the packaging of food and drug products.

- Consumer Product Safety Commission (CPSC) regulations: These regulations apply to the packaging of consumer products.

- Environmental Protection Agency (EPA) regulations: These regulations apply to the packaging of hazardous materials.

- Department of Transportation (DOT) regulations: These regulations apply to the packaging of hazardous materials that are transported.

10. What are the future trends in packaging?

- Sustainable packaging: There is a growing trend towards using sustainable packaging materials, such as recycled and biodegradable materials.

- Active packaging: Active packaging is packaging that interacts with the product it contains. For example, active packaging can be used to absorb oxygen or release antioxidants.

- Smart packaging: Smart packaging is packaging that is equipped with sensors and other devices that can track the condition of the product it contains.

- Personalized packaging: Personalized packaging is packaging that is customized to the individual consumer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Packers are responsible for the safe and efficient packing of products into various containers using automated machinery. They ensure that products are properly positioned, protected, and ready for storage or shipment. Some of the key job responsibilities of Machine Packers include:

1. Machine Operation

Operating and monitoring automated packing machinery to ensure smooth and efficient production.

- Setting up and adjusting packing lines to meet specific product requirements.

- Monitoring machine performance and troubleshooting any issues promptly.

2. Product Handling

Inspecting and verifying products to ensure they meet quality standards before packing.

- Loading products onto the packing line and positioning them correctly within the packaging.

- Ensuring that products are adequately protected and secured within the packaging.

3. Quality Control

Maintaining high standards of product presentation and packaging quality.

- Inspecting finished packages to ensure they meet company standards and customer specifications.

- Identifying and addressing any defects or inconsistencies in packaging.

4. Inventory Management

Tracking and maintaining inventory of packaging materials and supplies.

- Coordinating with other departments to ensure timely replenishment of packaging materials.

- Monitoring inventory levels to avoid shortages or overstocking.

Interview Preparation Tips

To ace an interview for a Machine Packer position, it’s crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some helpful interview preparation tips:

1. Research the Company and Position

Take time to research the company you’re applying to and the specific Machine Packer position. Understand their industry, products, and company culture. By doing so, you can tailor your answers to demonstrate how your skills and qualifications align with their needs.

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and qualifications. Practice answering these questions clearly and concisely, highlighting specific examples from your past work.

- Example Question: Describe a time when you faced a challenge in operating packing machinery and how you overcame it.

- Example Answer: “In my previous role, I encountered an issue with the alignment of products on the packing line. I promptly identified the problem and adjusted the settings accordingly, ensuring that products were properly positioned within the packaging.”

3. Emphasize Your Skills and Experience

Highlight your relevant skills and experience in your resume and during the interview. Focus on your ability to operate packing machinery, handle products with care, maintain quality standards, and work effectively in a fast-paced environment.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any details or gain additional insights into the role.

- Example Question: “Can you provide more information about the company’s sustainability initiatives and how they impact the Machine Packer role?”

5. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving on time for your interview. This shows that you value the opportunity and are respectful of the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Packer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.