Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Plug Shaper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Plug Shaper so you can tailor your answers to impress potential employers.

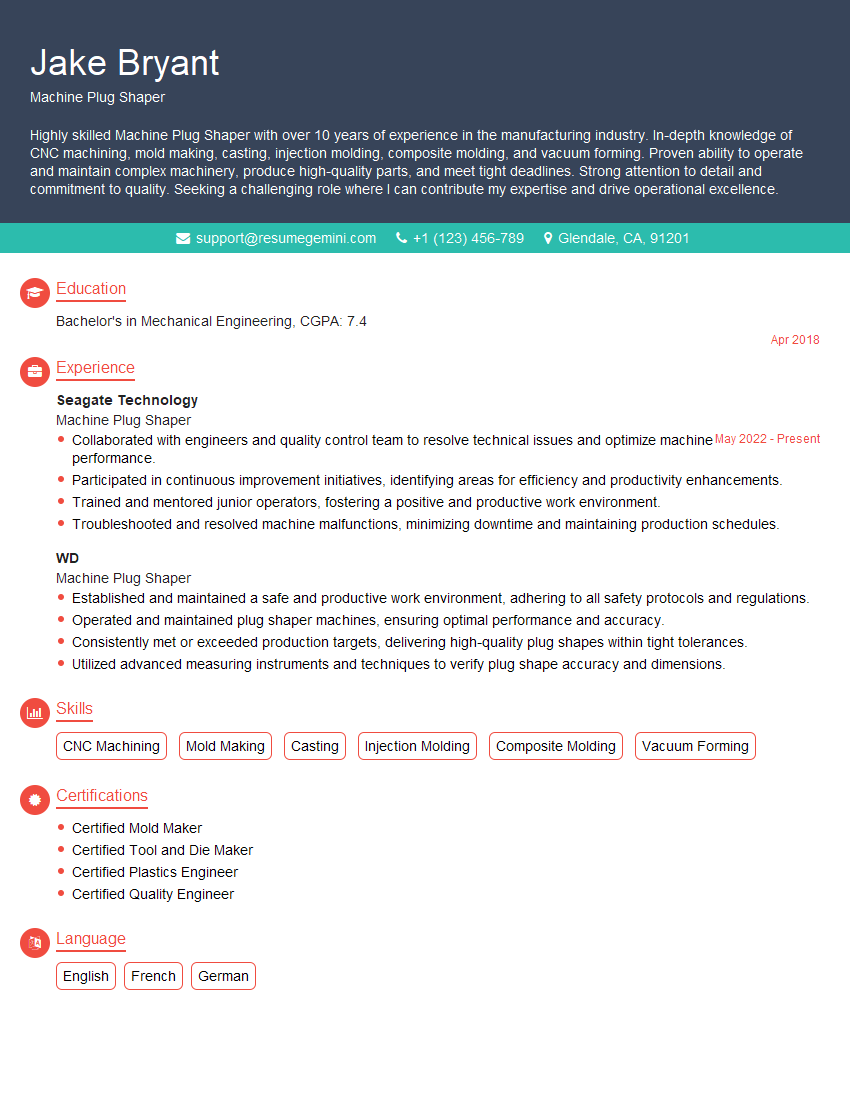

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Plug Shaper

1. Explain the process of setting up a plug shaper machine for various types of plugs.

The setup process for a plug shaper machine varies depending on the type of plug being produced. However, there are some general steps that are common to all setups:

- First, the machine must be calibrated to ensure that the cutting tool is positioned correctly.

- Next, the material to be cut is loaded into the machine.

- The cutting tool is then positioned over the material and the machine is started.

- The machine will automatically cut the plug to the desired shape and size.

2. How do you determine the correct cutting speed and feed rate for a plug shaper machine?

Factors to Consider

- The type of material being cut

- The thickness of the material

- The desired finish on the plug

General Guidelines

- For soft materials, such as wood or plastic, a higher cutting speed and feed rate can be used.

- For harder materials, such as metal, a lower cutting speed and feed rate must be used.

- For a finer finish, a lower cutting speed and feed rate must be used.

3. What are the different types of cutting tools that can be used in a plug shaper machine?

There are many different types of cutting tools that can be used in a plug shaper machine, including:

- Carbide-tipped cutting tools

- High-speed steel cutting tools

- Diamond-tipped cutting tools

The type of cutting tool that is used will depend on the material being cut and the desired finish.

4. How do you maintain a plug shaper machine?

To maintain a plug shaper machine, it is important to:

- Keep the machine clean and free of debris.

- Lubricate the machine regularly.

- Inspect the cutting tools regularly and replace them as needed.

- Calibrate the machine regularly.

5. What are the safety precautions that must be taken when operating a plug shaper machine?

When operating a plug shaper machine, it is important to take the following safety precautions:

- Always wear safety glasses.

- Always wear earplugs or ear muffs.

- Always wear gloves.

- Never operate the machine if you are under the influence of alcohol or drugs.

- Never reach into the machine while it is running.

- Always turn off the machine and unplug it before making any adjustments.

6. What are the different types of plugs that can be produced on a plug shaper machine?

The different types of plugs that can be produced on a plug shaper machine include:

- Solid plugs

- Hollow plugs

- Tapered plugs

- Cylindrical plugs

- Conical plugs

7. What are the advantages of using a plug shaper machine?

The advantages of using a plug shaper machine include:

- Can produce high-quality plugs with precision

- Can produce plugs in a variety of shapes and sizes

- Can be used to produce plugs from a variety of materials

- Can be automated to increase production speed

8. What are the disadvantages of using a plug shaper machine?

The disadvantages of using a plug shaper machine include:

- Can be expensive to purchase and maintain

- Can be complex to operate

- Can be dangerous if not used properly

9. What are the different applications for a plug shaper machine?

The different applications for a plug shaper machine include:

- Producing plugs for furniture

- Producing plugs for windows and doors

- Producing plugs for pipes and tubes

- Producing plugs for electrical outlets

10. What are the key features to look for when purchasing a plug shaper machine?

The key features to look for when purchasing a plug shaper machine include:

- The capacity of the machine

- The speed of the machine

- The accuracy of the machine

- The durability of the machine

- The price of the machine

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Plug Shaper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Plug Shaper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Plug Shapers are skilled professionals responsible for operating and maintaining complex machinery to produce high-quality plugs used in the automotive industry. Their primary duties involve planning, setting up, and operating machines to shape metal or plastic plugs.

1. Machine Operation and Setup

Set up and operate machine plug shapers, ensuring proper alignment and functioning.

- Calibrate and adjust machine settings to achieve optimal performance.

- Monitor machine operations, identify potential problems, and take corrective actions.

2. Material Handling

Load and unload metal or plastic rods into the machine.

- Inspect raw materials for defects and ensure they meet specifications.

- Handle and store materials safely and efficiently.

3. Quality Control

Inspect finished plugs for dimensional accuracy, surface finish, and other quality requirements.

- Use measuring tools and gauges to verify product quality.

- Identify and correct defects, ensuring products meet customer specifications.

4. Machine Maintenance

Perform basic maintenance on machines, such as lubrication, cleaning, and minor repairs.

- Monitor machine condition and report potential issues to supervisors.

- Follow established safety protocols and maintenance procedures.

Interview Tips

Preparing thoroughly for a Machine Plug Shaper interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific needs.

- Thoroughly review the job description to identify key responsibilities and qualifications.

- Use online resources, such as the company website and LinkedIn, to gather additional information.

2. Highlight Relevant Experience

Focus on showcasing your skills and experience that align with the job requirements.

- Quantify your accomplishments by providing specific examples of projects or tasks you have completed.

- Use action verbs to describe your responsibilities and contributions.

3. Practice Answering Interview Questions

Anticipate common interview questions and prepare thoughtful answers that demonstrate your knowledge and fit for the role.

- Consider questions related to your technical skills, experience with specific machines, and quality control practices.

- Practice your answers out loud to enhance your delivery and confidence.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the company and role.

- Inquire about the company’s production processes, growth plans, or any specific challenges related to the position.

- Questions related to training opportunities or professional development can demonstrate your eagerness to learn and grow.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive punctually.

- Choose attire that is clean, pressed, and reflects the professionalism of the workplace.

- Plan your route in advance to avoid any unexpected delays.

6. Stay Calm and Confident

It is natural to feel nervous during an interview, but try to remain calm and confident.

- Take deep breaths and maintain eye contact with the interviewer.

- Speak clearly and articulate your answers thoughtfully.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Plug Shaper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!