Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Puller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

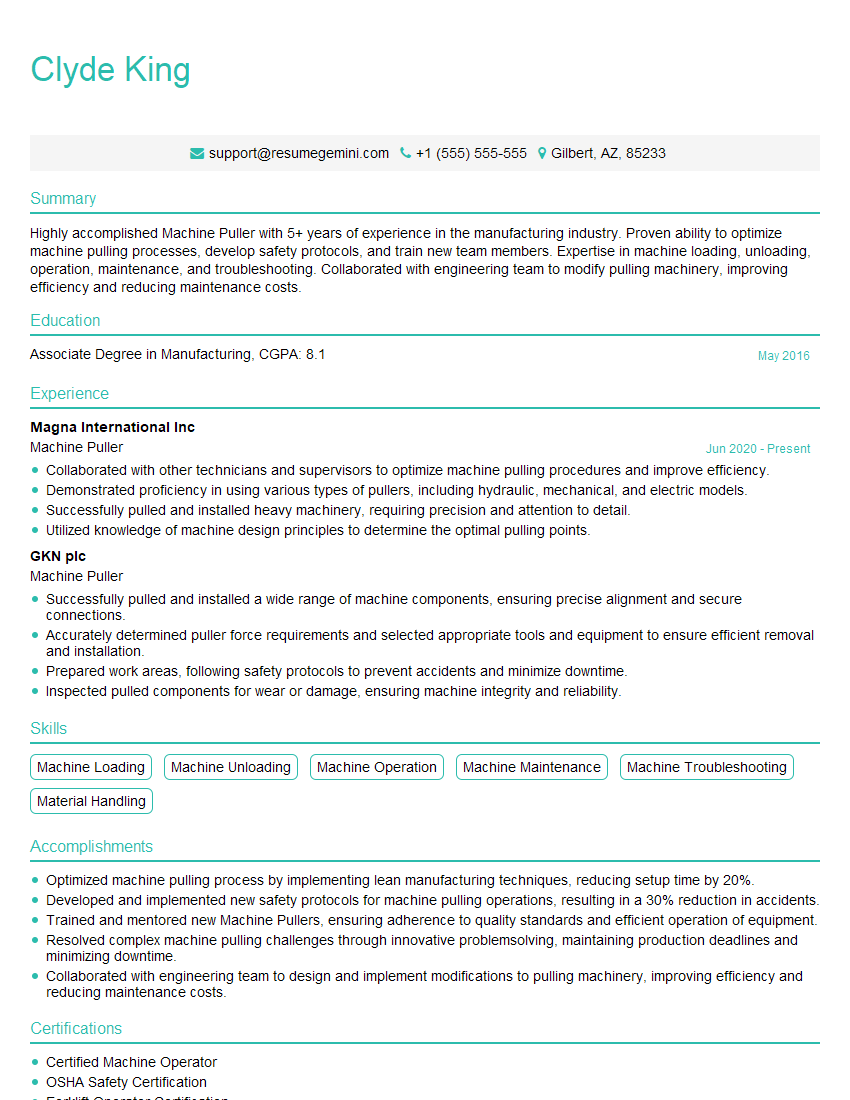

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Puller

1. What are the different types of machine pullers?

There are various types of machine pullers, each designed for specific applications. Some common types include:

- Hydraulic Pullers: Use hydraulic pressure to generate pulling force, offering high power and controlled operation.

- Mechanical Pullers: Utilize mechanical components such as gears or levers to create pulling force, providing manual or electric operation.

- Hand Pullers: Manually operated, lightweight pullers for smaller loads and confined spaces.

- Bearing Pullers: Specialized pullers designed specifically for removing bearings from shafts or housings.

2. What factors should be considered when selecting a machine puller?

Load Capacity:

- Determine the maximum weight or force required to be pulled.

- Ensure the puller’s capacity exceeds the anticipated load.

Puller Type:

- Hydraulic pullers provide higher power and control.

- Mechanical pullers are often more affordable and suitable for manual operation.

- Hand pullers are ideal for smaller loads and portability.

Jaw Type:

- Choose jaws that match the shape and size of the object being pulled.

- Internal jaws are used for pulling bearings, while external jaws are for general-purpose pulling.

3. What safety precautions should be taken when using a machine puller?

To ensure safe operation, it is crucial to observe the following safety precautions:

- Inspect the puller and components before use, checking for any damage or defects.

- Secure the workpiece firmly to prevent movement during pulling.

- Wear appropriate personal protective equipment, such as safety glasses and gloves.

- Follow the manufacturer’s instructions for proper operation and maintenance.

- Do not exceed the puller’s rated capacity to avoid overloading.

4. How do you inspect and maintain a machine puller?

Regular inspection and maintenance are essential for optimal performance and safety:

- Inspection:

- Check for leaks, damage, or corrosion on the hydraulic system, if applicable.

- Inspect jaws for wear or damage.

- Verify that all bolts and connections are tight.

- Maintenance:

- Lubricate moving parts as per manufacturer’s recommendations.

- Clean the puller regularly to prevent dirt and debris accumulation.

- Calibrate the puller periodically to ensure accuracy.

5. What troubleshooting steps would you take if a machine puller fails to operate properly?

If a machine puller malfunctions, it is important to troubleshoot the issue systematically:

- Check for obvious issues, such as disconnected hoses or loose connections.

- Verify that the hydraulic system is functioning correctly (if applicable).

- Inspect the jaws for damage or wear that may hinder proper engagement.

- Consult the manufacturer’s manual for specific troubleshooting procedures.

- If the issue persists, seek professional assistance from a qualified mechanic.

6. What techniques can be used to improve the efficiency and safety of machine pulling operations?

To enhance efficiency and safety, consider the following techniques:

- Use the appropriate puller for the task: Matching the puller’s capacity and type to the specific application ensures optimal performance.

- Properly secure the workpiece: Prevent movement during pulling to avoid accidents and ensure accurate results.

- Apply appropriate force: Do not exceed the puller’s rated capacity to avoid overloading and potential damage.

- Use multiple pulling points: Distribute the load evenly to prevent excessive force on any single point.

- Operate the puller in a controlled manner: Slow and steady pulling minimizes the risk of accidents and allows for better control.

7. Can you describe any specific projects or experiences where you used machine pullers to successfully remove or install components?

Provide detailed examples of practical experiences using machine pullers:

- Describe the specific application, including the type of component being removed or installed.

- Explain the challenges encountered and how you overcame them.

- Highlight the techniques and strategies employed to ensure safety and efficiency.

- Quantify the results achieved, if possible (e.g., time saved, improved accuracy).

8. How would you handle a situation where a machine puller is not available for a specific task?

Discuss potential alternatives and solutions:

- Consider using other tools or equipment that could perform the task safely and effectively.

- Explore the possibility of renting or borrowing a machine puller from a colleague or supplier.

- If necessary, modify the approach to the task to accommodate the absence of a machine puller.

- Prioritize safety and seek assistance if required to ensure proper execution of the task.

9. How do you stay updated on the latest advancements and best practices in machine pulling techniques?

Describe methods for continuous learning and improvement:

- Attend industry conferences and workshops.

- Read technical publications and articles.

- Consult with experienced professionals in the field.

- Obtain relevant certifications or training.

10. If given a complex machine pulling task, how would you approach it to ensure success?

Outline a structured approach:

- Assessment: Evaluate the task, identify potential challenges, and gather necessary information.

- Planning: Develop a detailed plan, including the selection of appropriate equipment and safety measures.

- Preparation: Ensure the workpiece is properly secured, and all necessary tools and materials are available.

- Execution: Carry out the pulling operation carefully, following the established plan and safety protocols.

- Evaluation: Inspect the results, verify accuracy, and document the process for future reference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Puller plays a crucial role in manufacturing and industrial settings, operating and maintaining specialized machinery. Here are the key job responsibilities:

1. Machine Operation

The primary duty is to operate a wide range of machines, including lathes, milling machines, grinders, and CNC machines.

- Interpret blueprints and technical drawings to understand machine specifications and requirements.

- Set up and adjust machines to meet specific production goals.

- Monitor machine performance, make necessary adjustments, and troubleshoot any issues.

- Ensure the safe and efficient operation of machinery.

2. Material Handling

Involves handling and maneuvering heavy materials within the production process.

- Load and unload raw materials into designated areas.

- Operate cranes, hoists, or forklifts to transport materials.

- Ensure the safe movement and storage of materials.

3. Quality Control

Plays a role in maintaining quality standards in the manufacturing process.

- Inspect and measure finished products to ensure they meet specifications.

- Identify and rectify any defects or inconsistencies.

- Adhere to quality control procedures and regulations.

- Provide feedback and suggestions to improve production efficiency and quality.

4. Machine Maintenance

Responsible for the basic maintenance and upkeep of the machinery they operate.

- Perform routine cleaning, lubrication, and minor repairs.

- Identify potential problems and report them to supervisors or maintenance personnel.

- Follow established maintenance schedules to ensure optimal machine performance.

Interview Tips

To help you ace your Machine Puller interview, here are some preparation tips and interview hacks:

1. Research the Company and Industry

Show that you’re genuinely interested in the company and the industry. Visit the company’s website, study their products or services, and understand their market position.

- Highlight how your skills and experience align with the company’s needs.

- Research the latest industry trends and advancements to demonstrate your knowledge.

2. Practice Common Interview Questions

Prepare for general interview questions, such as why you’re interested in the position and what your strengths and weaknesses are. Also, anticipate industry-specific questions about machine operation, material handling, and quality control.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Showcase Your Technical Skills

Discuss your experience operating various machines, including lathes, milling machines, and CNC machines. Highlight your ability to interpret blueprints, set up and adjust machines, and troubleshoot problems.

- If you have certifications or training in specific machine operations, mention them.

- Be prepared to discuss your knowledge of quality control procedures and your ability to inspect finished products.

4. Emphasize Safety and Efficiency

Emphasize your commitment to safety in the workplace. Explain your understanding of machine safety regulations and your experience in preventing accidents and injuries.

- Highlight your ability to work efficiently and meet production goals while maintaining high quality standards.

- Share any experience in implementing process improvements or reducing waste in the manufacturing process.

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the position, the company, or the industry. This shows that you’re engaged and interested in the opportunity.

- Ask about the company’s growth plans or recent projects.

- Inquire about training or development opportunities available to employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Puller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!