Feeling lost in a sea of interview questions? Landed that dream interview for Machine Puller Over but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Puller Over interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

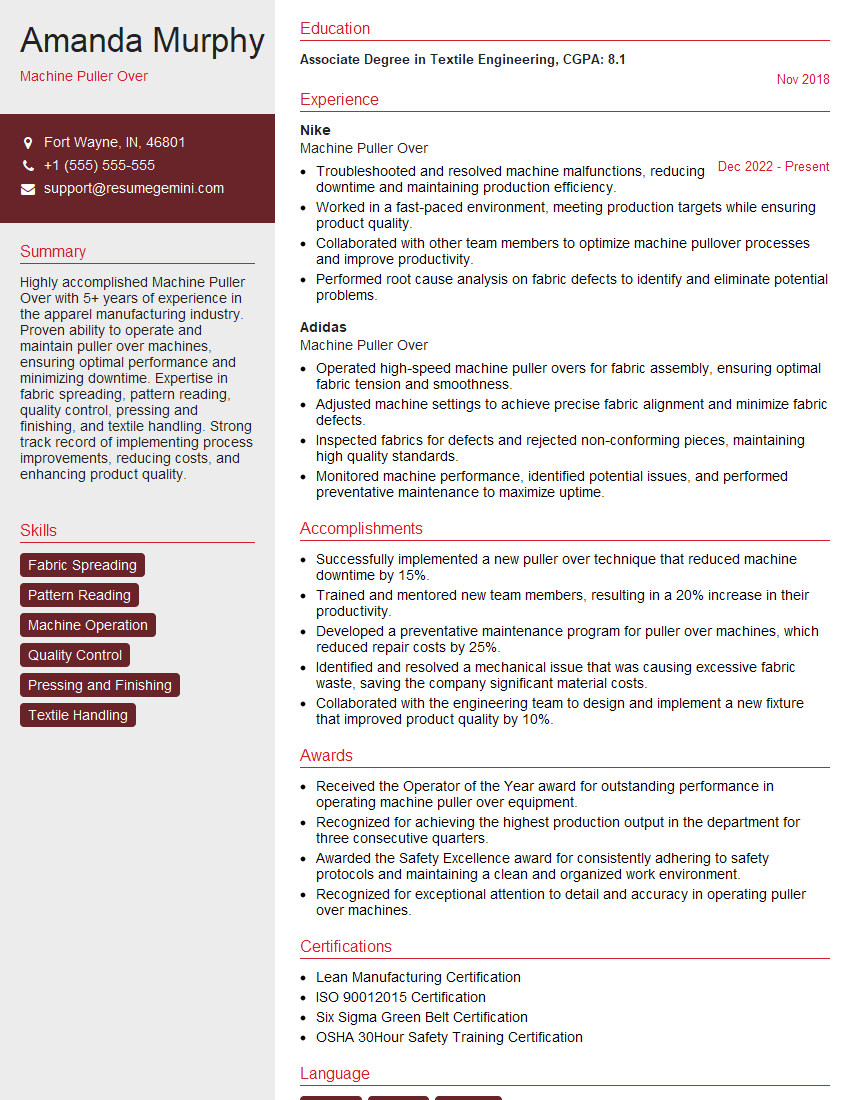

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Puller Over

1. Briefly describe the function and operation of a machine puller over?

- A machine puller over is a specialized machine used in the garment industry to stretch and secure fabric over a garment mold or form, creating a smooth and tight fit for the garment.

- It operates by pulling the fabric over the mold using a combination of mechanical and vacuum systems, ensuring an even and wrinkle-free application.

2. What are the key mechanical components of a machine puller over and their respective functions?

- Head: Holds the mold and moves up and down to stretch the fabric.

- Base: Supports the mold and provides a stable base for the machine.

- Vacuum System: Creates a vacuum beneath the mold to hold the fabric in place.

- Hydraulic System: Powers the head and vacuum systems.

- Control Panel: Allows the operator to set parameters such as speed and pressure.

3. Describe the different types of molds used in machine puller overs and their specific applications?

- Male Molds: Used to shape the outside of a garment, such as t-shirts, polo shirts, and sweatshirts.

- Female Molds: Used to shape the inside of a garment, such as jackets, coats, and dresses.

- Combination Molds: Can be used for both male and female shaping.

- Custom Molds: Designed to produce garments with specific shapes and dimensions.

4. Explain the importance of fabric selection and preparation for optimal machine pull over operations?

- Fabric should be wrinkle-free and have the appropriate stretch and elasticity for the garment design.

- Proper fabric preparation, such as steaming or pre-stretching, enhances the pulling process and reduces defects.

- Selecting the right fabric ensures the garment fits snugly and maintains its shape after pulling.

5. How do you troubleshoot common problems encountered while operating a machine puller over, such as fabric puckering or uneven stretching?

- Puckering: Adjust vacuum pressure, check for fabric defects, or use a different mold size.

- Uneven Stretching: Inspect the mold surface for unevenness, adjust head pressure, or check the fabric tension.

- Sagging: Increase head pressure, use a stronger fabric, or check the mold for proper fit.

- Wrinkling: Steam the fabric before pulling or use a wrinkle-resistant fabric.

6. What maintenance and safety procedures are essential for the proper operation and longevity of a machine puller over?

- Regular cleaning and lubrication of mechanical components.

- Vacuum system inspection and filter replacement.

- Checking for damaged or loose parts.

- Ensuring proper ventilation to prevent heat buildup.

- Following safety guidelines for operating machinery.

7. Describe the quality control measures implemented to ensure the accuracy and consistency of garments produced using a machine puller over?

- Regular mold inspection and calibration.

- Monitoring fabric tension and head pressure during the pulling process.

- Visual inspection of garments for defects, such as puckering or uneven stretching.

- Maintaining records of production parameters and quality checks.

8. How do you optimize the efficiency of a machine puller over operation while maintaining garment quality?

- Using the appropriate mold size and fabric for the garment design.

- Fine-tuning the pulling parameters (speed, pressure, vacuum) for each fabric type.

- Minimizing machine downtime through proper maintenance and troubleshooting.

- Training operators on best practices and quality standards.

9. Discuss the potential applications of machine puller overs beyond the garment industry?

- Covering automotive seats and interiors.

- Creating upholstered furniture and home décor items.

- Stretching and shaping materials in medical and industrial settings.

10. What advancements in machine puller over technology have you encountered or expect to see in the future?

- Automated fabric feeding and positioning systems.

- Integrated quality control sensors for real-time defect detection.

- Remote monitoring and control capabilities for improved efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Puller Over.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Puller Over‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Puller Over is responsible for operating a pull-over machine to seal and close packaging products, such as bags, pouches, and containers. Their primary duties include ensuring the smooth operation of the machine and maintaining product quality.

1. Machine Operation

The Machine Puller Over is expected to:

- Set up and operate the pull-over machine according to established procedures.

- Monitor the machine during operation, ensuring proper tension and alignment of materials.

- Identify and resolve minor machine malfunctions and perform basic maintenance tasks.

2. Product Handling

The Machine Puller Over is expected to:

- Load and unload products onto the pull-over machine.

- Inspect products for defects or damage before and after sealing.

- Ensure that products are sealed to the required specifications.

3. Quality Control

The Machine Puller Over is expected to:

- Monitor the sealing process to ensure that products meet quality standards.

- Identify and reject defective products.

- Maintain records of production output and quality control.

4. Safety and Maintenance

The Machine Puller Over is expected to:

- Follow established safety procedures and wear appropriate personal protective equipment.

- Keep the work area clean and organized.

- Report any potential hazards or safety concerns.

Interview Tips

Preparing for an interview can maximize your chances of making a great impression and landing the job. Here are some effective tips specifically tailored for the Machine Puller Over role.

1. Research the Company and Industry

Demonstrate your interest and enthusiasm by researching the company’s history, products, and industry trends. This shows the interviewer that you are genuinely interested in the position and have taken the time to learn about their organization.

- Visit the company’s website: Explore the “About Us”, “Products/Services”, and “News” sections.

- Check industry publications: Subscribe to magazines or follow industry blogs to stay updated on current trends and best practices.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions. This will help you feel more confident and articulate during the actual interview.

- Core Competencies: Showcase your skills and experience relevant to the key job responsibilities discussed earlier. Highlight specific examples from your previous role.

- Behavioral Questions: Use the STAR method (Situation, Task, Action, Result) to structure your answers to behavioral questions, providing concrete examples of your problem-solving abilities and work ethic.

3. Emphasize Safety and Quality

In this role, safety and quality are of utmost importance. Highlight your understanding of safety protocols and your commitment to maintaining high-quality standards in everything you do.

- Safety-First Mindset: Share examples of how you prioritize safety in your work, such as adhering to proper procedures or identifying potential hazards.

- Quality Assurance: Emphasize your attention to detail and your ability to consistently meet or exceed quality expectations.

4. Show Your Work Ethic

Machine Puller Overs are known for their diligence and productivity. Showcase your strong work ethic and willingness to go the extra mile.

- Enthusiasm and Motivation: Express your passion for manufacturing and your eagerness to contribute to the team’s success.

- Results-Oriented: Quantify your accomplishments in previous roles, using specific metrics to demonstrate your impact on productivity or efficiency.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Puller Over role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.