Are you gearing up for a career in Machine Rigger? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Rigger and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

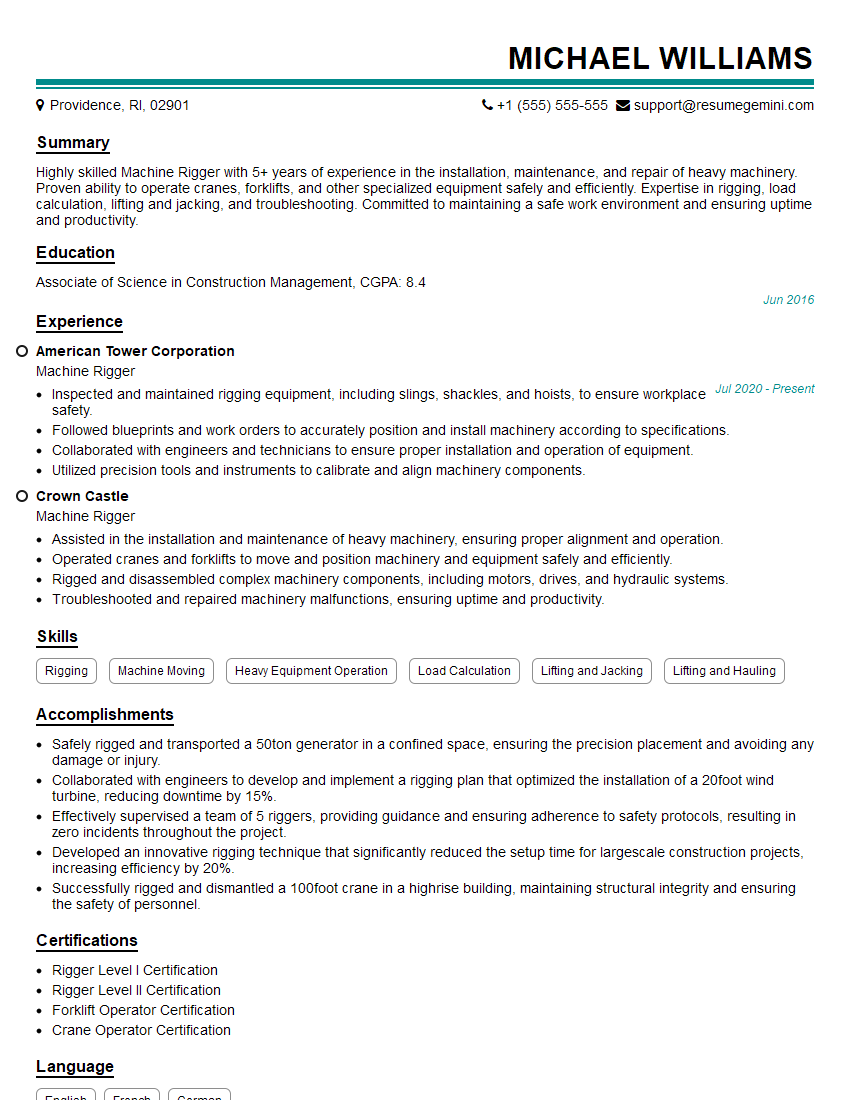

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Rigger

1. What is the proper sequence for rigging a load?

- Inspect the load and determine its center of gravity.

- Choose the appropriate rigging equipment and inspect it for any damage.

- Attach the rigging equipment to the load and secure it properly.

- Lift the load and transport it to its destination.

- Secure the load at its destination and remove the rigging equipment.

2. What are the different types of rigging equipment, and what are their uses?

Slings:

- Nylon slings: Lightweight and flexible, used for lifting delicate loads.

- Polyester slings: Stronger and more durable than nylon slings, used for lifting heavier loads.

- Wire rope slings: Strongest and most durable type of sling, used for lifting extremely heavy loads.

Hoists:

- Manual hoists: Operated by hand, used for lifting smaller loads.

- Electric hoists: Powered by electricity, used for lifting heavier loads.

Pulleys:

- Fixed pulleys: Do not move, used to change the direction of pull.

- Movable pulleys: Move along with the load, used to reduce the amount of force required to lift the load.

Blocks:

- Single blocks: Consist of a single pulley, used to change the direction of pull.

- Double blocks: Consist of two pulleys, used to reduce the amount of force required to lift the load.

- Triple blocks: Consist of three pulleys, used to further reduce the amount of force required to lift the load.

3. What are the dangers associated with rigging, and how can they be prevented?

- Overloading: Never lift a load that is heavier than the rated capacity of the rigging equipment.

- Improper rigging: Ensure that the rigging equipment is attached to the load properly and that the load is balanced.

- Uneven lifting: Lift the load evenly to prevent it from swinging or tipping.

- Overhead hazards: Be aware of any overhead hazards, such as power lines or trees, when lifting a load.

- Personal protective equipment: Always wear proper personal protective equipment, such as safety glasses, gloves, and hard hats, when rigging.

4. What are the different types of knots used in rigging, and what are their uses?

- Bowline knot: Used to create a loop in the end of a rope.

- Clove hitch: Used to secure a rope to a post or other object.

- Figure-eight knot: Used to join two ropes together.

- Square knot: Used to join two ropes together.

- Trucker’s hitch: Used to secure a rope to a load.

5. What is the difference between a tagline and a bridle?

- Tagline: A rope used to control the movement of a load.

- Bridle: A sling made of multiple ropes that is used to distribute the weight of a load.

6. What is the importance of load testing rigging equipment?

- To ensure that the rigging equipment is safe to use.

- To determine the rated capacity of the rigging equipment.

- To identify any potential defects in the rigging equipment.

7. What are the different types of cranes used in rigging, and what are their capabilities?

Mobile cranes:

- Can be moved from one location to another.

- Have a variety of boom lengths and capacities.

Tower cranes:

- Fixed in one location.

- Have a very long reach.

Overhead cranes:

- Mounted on a runway overhead.

- Used for lifting loads in a fixed area.

8. What are the factors to consider when choosing a crane for a rigging job?

- The weight of the load.

- The distance the load needs to be lifted.

- The height of the lift.

- The location of the lift.

- The availability of power.

9. What is the difference between a hydraulic crane and a pneumatic crane?

- Hydraulic cranes: Use hydraulic fluid to power the crane’s movements.

- Pneumatic cranes: Use compressed air to power the crane’s movements.

10. What are the safety precautions to take when operating a crane?

- Never overload the crane.

- Always inspect the crane and rigging equipment before use.

- Be aware of your surroundings and overhead hazards.

- Always wear proper personal protective equipment.

- Never leave a crane unattended while it is in operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Riggers are responsible for the safe and efficient movement and installation of heavy machinery and equipment within various industrial settings. Their primary tasks include:

1. Equipment Preparation and Assembly

Preparing and assembling machinery, including disassembling, cleaning, and aligning components.

- Inspecting equipment for damage and ensuring its proper functioning

- Identifying and using appropriate tools and rigging equipment for various tasks

2. Rigging and Lifting Operations

Rigging and lifting heavy machinery using cranes, hoists, and other specialized equipment.

- Calculating load weights, determining rigging points, and selecting appropriate rigging gear

- Using hand signals and communicating effectively with crane operators and other team members

3. Machinery Installation and Alignment

Installing and aligning machinery in accordance with specifications and safety standards.

- Leveling, bolting, and securing equipment to ensure stability and proper operation

- Verifying alignment and tolerances using precision measuring tools and instruments

4. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting equipment malfunctions.

- Monitoring equipment performance, identifying potential issues, and taking corrective actions

- Collaborating with maintenance technicians and other specialists to diagnose and resolve complex problems

Interview Tips

To ace your interview for a Machine Rigger position, follow these tips:

1. Research and Practice

Thoroughly research the company, the industry, and the specific role. Practice answering common interview questions related to your skills, experience, and safety protocols.

- Be prepared to discuss your knowledge of rigging techniques, equipment, and industry standards.

- Highlight your understanding of safety regulations and your commitment to maintaining a safe work environment.

2. Emphasize Your Experience

Quantify your experience and provide specific examples of your accomplishments. Use the STAR method (Situation, Task, Action, Result) to describe your involvement in rigging projects.

- Share instances where you successfully rigged and lifted heavy machinery, ensuring its safe installation.

- Discuss your troubleshooting skills and how you resolved equipment malfunctions effectively.

3. Highlight Safety and Attention to Detail

Emphasize your commitment to safety and adherence to industry regulations. Showcase your ability to assess risks, identify hazards, and implement appropriate safety measures.

- Describe your experience in developing and implementing rigging plans that prioritized safety and efficiency.

- Highlight your attention to detail and accuracy when performing rigging operations.

4. Showcase Your Teamwork and Communication Skills

Machine Riggers often work as part of a team. Showcase your ability to collaborate effectively, communicate clearly, and follow instructions.

- Share examples of how you have worked effectively with crane operators, maintenance technicians, and other team members.

- Demonstrate your ability to use hand signals and verbal communication to convey instructions and ensure safety during rigging operations.

5. Prepare Questions

Preparing thoughtful questions for the interviewer shows your interest in the position and the company. Ask questions that relate to the role, the company culture, and the industry outlook.

- Inquire about the company’s safety policies and procedures.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Rigger, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Rigger positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.