Are you gearing up for an interview for a Machine Rough Rounder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Rough Rounder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

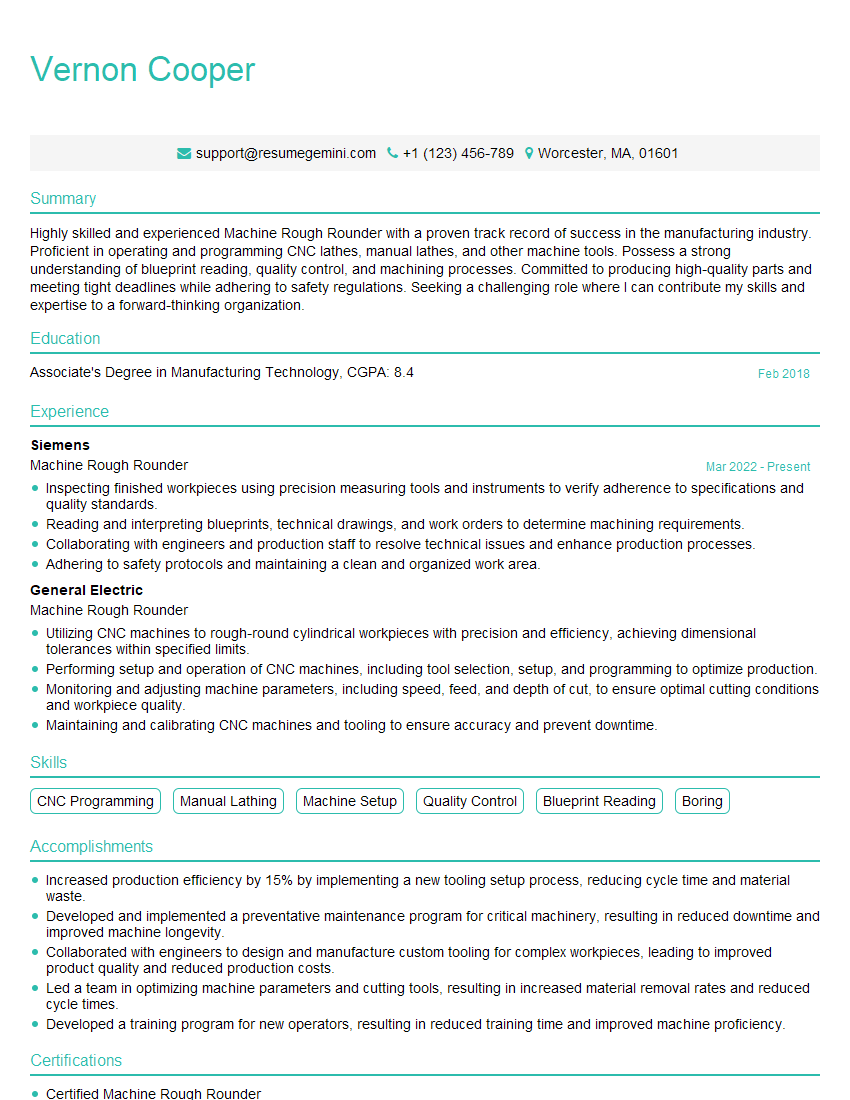

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Rough Rounder

1. Can you describe the process of rough rounding a workpiece on a lathe machine?

- Rough rounding is a process of removing excess material from a workpiece using a lathe machine.

- It is typically done to prepare the workpiece for further machining operations, such as finishing or grinding.

2. What are the different types of rough rounding tools?

Types of Rough Rounding Tools

- There are two main types of rough rounding tools: single-point tools and multi-point tools.

- Single-point tools consist of a single cutting edge.

- Multi-point tools consist of multiple cutting edges.

3. What are the factors that affect the surface finish of a rough rounded workpiece?

- The surface finish of a rough rounded workpiece is affected by a number of factors, including:

- The type of rough rounding tool used

- The speed of the workpiece

- The feed rate of the tool

- The depth of cut

4. What are the safety precautions that must be taken when rough rounding a workpiece?

- When rough rounding a workpiece, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, gloves, and a lab coat.

- Secure the workpiece properly in the lathe chuck.

- Use a sharp cutting tool.

- Control the speed of the workpiece and the feed rate of the tool.

5. What are some of the common problems that can occur when rough rounding a workpiece?

- Some of the common problems that can occur when rough rounding a workpiece include:

- Chatter

- Tool breakage

- Poor surface finish

- Workpiece damage

6. How do you troubleshoot and resolve problems that occur when rough rounding a workpiece?

- To troubleshoot and resolve problems that occur when rough rounding a workpiece, you can take the following steps:

- Determine the cause of the problem.

- Make necessary adjustments to the machine or the workpiece.

- Restart the rough rounding process.

7. What are the different types of materials that can be rough rounded?

- A variety of materials can be rough rounded, including:

- Metals

- Plastics

- Wood

8. What are the advantages of rough rounding a workpiece?

- There are a number of advantages to rough rounding a workpiece, including:

- It removes excess material quickly and efficiently.

- It can improve the surface finish of the workpiece.

- It can make it easier to perform subsequent machining operations.

9. What are the disadvantages of rough rounding a workpiece?

- There are some disadvantages to rough rounding a workpiece, including:

- It can be time-consuming.

- It can generate a lot of noise.

- It can create dust and debris.

10. What are some of the latest trends in rough rounding technology?

- Some of the latest trends in rough rounding technology include:

- The use of CNC machines

- The development of new cutting tools

- The use of advanced materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Rough Rounder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Rough Rounder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Machine Rough Rounder, you will be responsible for carrying out various tasks related to rough rounding of metal parts in a manufacturing setting. Your primary duties will include:

1. Operating Machine and Equipment

You will be responsible for operating and maintaining various machines and equipment used in the rough rounding process. This includes lathes, milling machines, grinders, and other specialized equipment.

- Ensure that machines are calibrated and set up correctly.

- Load and unload workpieces into and out of the machines.

- Monitor the machining process and make adjustments as needed.

2. Rough Rounding Metal Parts

Your main responsibility will be to rough round metal parts as per the specifications provided. This involves removing excess material and shaping the workpieces to their desired dimensions.

- Use appropriate cutting tools and techniques to remove material.

- Inspect workpieces regularly to ensure accuracy and quality.

- Make necessary adjustments to the machine or process to maintain required tolerances.

3. Inspecting and Measuring

You will be responsible for inspecting and measuring the workpieces to ensure they meet the required specifications. This involves using various measuring instruments and gauges.

- Inspect workpieces visually and using precision measuring tools.

- Compare measurements to specifications and identify any discrepancies.

- Record inspection results and report any defects or deviations.

4. Maintaining Work Area and Equipment

As part of your role, you will be responsible for maintaining a clean and organized work area. This includes cleaning and maintaining the machines and equipment, as well as disposing of waste materials.

- Clean and lubricate machines and equipment on a regular basis.

- Keep work area clean and free of debris.

- Follow safety protocols and maintain a safe working environment.

Interview Tips

Preparing for an interview for a Machine Rough Rounder role requires a combination of technical knowledge and a demonstration of your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of their business, their values, and what they are looking for in a candidate.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your technical skills and experience relevant to the job requirements. Quantify your accomplishments whenever possible using specific examples and metrics.

- Describe your experience operating and maintaining machines and equipment.

- Provide examples of your ability to rough round metal parts to precise specifications.

- Highlight your inspection and measurement skills, including any certifications or training you have.

3. Practice Your Answers

Take some time to prepare answers to common interview questions. This will help you feel more confident and articulate during the interview. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Prepare answers to questions about your technical skills and experience.

- Rehearse your answers to behavioral questions, such as “Tell me about a time when you faced a challenge at work.”

- Practice answering questions about your career goals and how they align with the company’s.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you take the interview seriously.

- Choose business casual attire that is clean and pressed.

- Arrive at the interview location 10-15 minutes early to allow time for any unexpected delays.

- Be polite and respectful to everyone you encounter during the interview process.

Next Step:

Now that you’re armed with the knowledge of Machine Rough Rounder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Rough Rounder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini