Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Set-Up position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

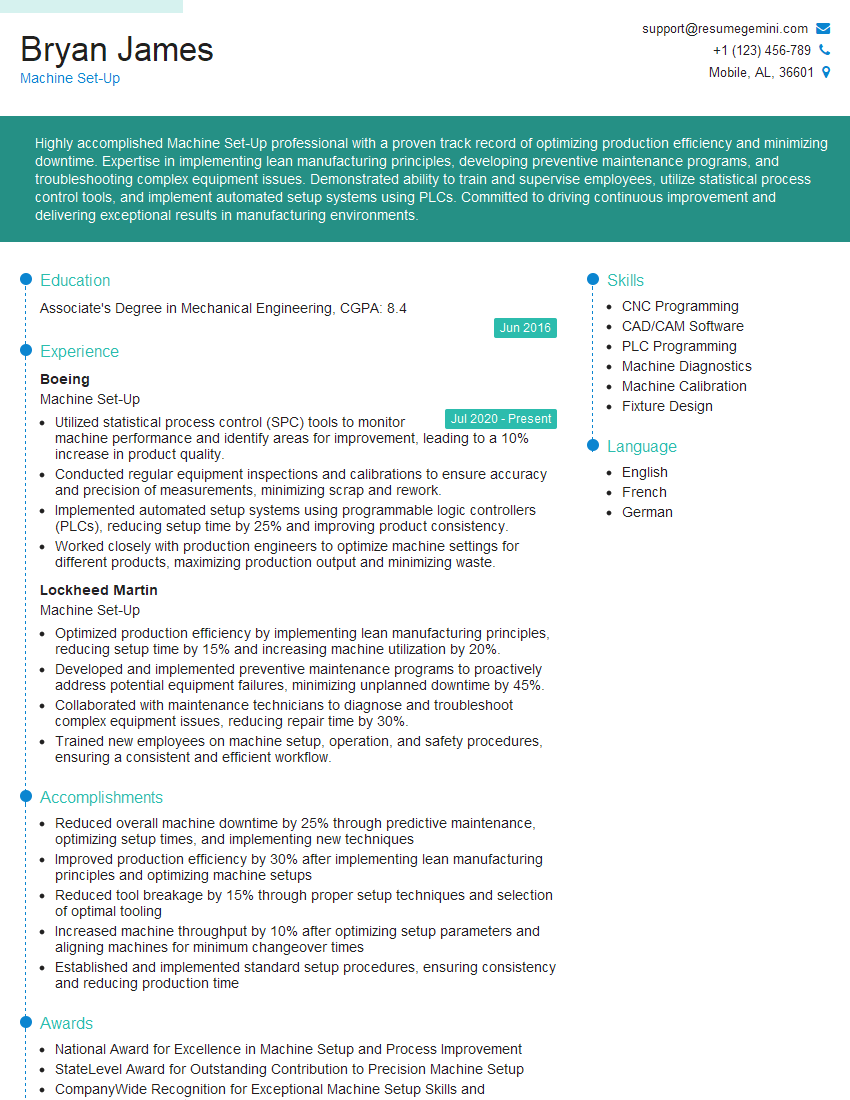

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Set-Up

1. Explain the process of setting up a CNC machine for a new job?

Sample Answer:

- Review the job plan and identify the required materials and tools.

- Secure the workpiece in the machine and align it with the coordinate system.

- Install the appropriate cutting tools and set the tool offsets.

- Create or load the CNC program into the machine’s controller.

- Set the machine parameters, such as spindle speed, feed rate, and cutting depth.

- Perform a dry run to verify the program and ensure proper operation.

2. What techniques do you use to troubleshoot and resolve machine setup issues?

- Identify the source of the problem: Check the machine’s error codes, inspect the workpiece and tools, and review the CNC program.

- Analyze the error messages: Determine the cause of the error and identify potential solutions.

- Perform diagnostic tests: Run diagnostics to isolate the issue and identify faulty components.

- Make adjustments: Modify the machine parameters, tools, or program to correct the problem.

- Consult with experts: Seek assistance from technical support, engineers, or experienced technicians if needed.

3. How do you optimize machine setups to improve efficiency and accuracy?

- Use standard setup procedures: Establish consistent and efficient setup processes for different types of jobs.

- Employ precision measuring tools: Utilize calipers, micrometers, and other tools to ensure accurate workpiece alignment and tool settings.

- Optimize tool selection and sequencing: Choose the appropriate tools and sequence them efficiently to minimize tool changes and setup times.

- Leverage technology: Use computer-aided setup software or other tools to facilitate setup and optimize parameters.

- Monitor and adjust parameters: Regularly monitor machine performance and adjust parameters as needed to maintain accuracy and productivity.

4. Describe the importance of safety precautions during machine setup?

- Follow proper lockout/tagout procedures: Ensure the machine is powered down and isolated before performing any setup tasks.

- Wear appropriate PPE: Use safety glasses, gloves, and ear protection as necessary.

- Secure the workpiece and tools: Properly clamp the workpiece and ensure all tools are securely fastened.

- Inspect for hazards: Check for any potential hazards, such as sharp edges, loose wires, or tripping hazards.

- Be aware of moving parts: Stay clear of moving machine components and ensure all guards are in place.

5. Explain the role of preventive maintenance in ensuring machine setup accuracy?

- Regularly inspect and clean the machine: Remove debris, clean bearings, and lubricate moving parts to prevent wear and tear.

- Check and calibrate measuring tools: Ensure tools are accurate and calibrated regularly to maintain precision during setup.

- Replace worn components: Identify and replace worn or faulty components that could affect machine accuracy.

- Follow manufacturer’s recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines to optimize machine performance.

- Monitor machine performance: Track machine metrics and identify any deviations that may indicate a need for maintenance.

6. Describe your experience with different types of machine setups, such as turning, milling, and grinding?

- Turning: Setup and operation of CNC lathes for turning operations, including facing, boring, grooving, and threading.

- Milling: Setup and operation of CNC milling machines for contouring, drilling, tapping, and pocketing operations.

- Grinding: Setup and operation of CNC grinders for surface grinding, cylindrical grinding, and tool grinding operations.

- Other specialized setups: Experience with setups for non-traditional machining processes, such as laser cutting and wire EDM.

7. What strategies do you employ to minimize setup time and maximize production efficiency?

- Use quick-change tooling systems: Implement systems that allow for rapid tool changes to reduce setup times.

- Utilize pre-set tooling: Prepare tools offline to eliminate the need for manual adjustments during setup.

- Optimize toolpath generation: Use software to generate efficient toolpaths that minimize tool changes and non-cutting motions.

- Implement automated setup procedures: Use automation to perform repetitive setup tasks, such as workpiece loading and tool selection.

- Train operators on efficient setup techniques: Ensure operators are trained on best practices to minimize setup times.

8. How do you stay updated with the latest technologies and trends in machine setup?

- Attend industry conferences and workshops: Participate in events to learn about new technologies and network with experts.

- Read technical publications: Subscribe to industry magazines and journals to stay informed about advancements.

- Connect with industry professionals: Establish relationships with suppliers, manufacturers, and other professionals in the field.

- Utilize online resources: Explore websites, forums, and social media groups dedicated to machine setup and technology.

- Attend training courses: Enhance skills and knowledge through formal training programs offered by manufacturers or educational institutions.

9. Can you describe a specific instance where you successfully implemented a new or improved machine setup procedure that resulted in significant improvements?

- Describe the problem or challenge encountered: Explain the issue with the existing setup procedure and its impact.

- Explain the solution you developed: Provide details of the new or improved setup procedure you implemented.

- Quantify the results: State the specific improvements achieved, such as reduced setup times, increased accuracy, or improved productivity.

- Highlight your contributions: Emphasize your role in the development and implementation of the successful solution.

10. How do you handle situations where you encounter unforeseen challenges or unexpected deviations during machine setup?

- Remain calm and assess the situation: Maintain composure and analyze the situation to identify the cause of the issue.

- Consult documentation and resources: Refer to manuals, drawings, or other resources to troubleshoot the problem.

- Seek assistance from colleagues or experts: Engage with experienced colleagues or technical support for guidance and assistance.

- Experiment with different solutions: Explore alternative setup configurations or parameters to resolve the issue.

- Document the solution and lessons learned: Record the solution implemented and any valuable insights gained from the experience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Set-Up.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Set-Up‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Set-Up is responsible for preparing and operating a variety of machines to produce a diverse range of products. The key job responsibilities involve:

1. Machine Set-Up and Operation

Installing, configuring, and adjusting machines according to production specifications, ensuring optimal performance and quality output.

2. Production Monitoring

Monitoring machine operations, identifying potential issues, and making necessary adjustments to maintain production efficiency and product quality.

3. Troubleshooting and Maintenance

Diagnosing and resolving machine malfunctions, conducting routine maintenance, and performing minor repairs to minimize downtime and ensure smooth operations.

4. Quality Control

Inspecting and testing products to ensure they meet quality standards, adhering to established procedures and specifications.

5. Process Improvement

Continuously evaluating and identifying areas for process improvement, implementing changes to enhance efficiency, reduce waste, and improve product quality.

Interview Tips

To ace the interview for a Machine Set-Up position, it’s crucial to prepare effectively. Here are some valuable tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and culture. Understand the specific requirements of the Machine Set-Up role and how your skills align with them.

2. Highlight Your Technical Skills

Emphasize your proficiency in machine setup, operation, and maintenance. Share specific examples of your ability to diagnose and resolve machine issues, as well as your experience with quality control procedures.

3. Demonstrate Problem-Solving Abilities

Provide instances where you successfully identified and addressed production bottlenecks or resolved complex machine malfunctions. Explain your logical reasoning and the steps taken to achieve positive outcomes.

4. Showcase Your Attention to Detail

Highlight your meticulous approach to machine setup and quality control. Explain how you ensure accuracy and precision in your work and how you maintain rigorous standards.

5. Emphasize Your Work Ethic

Convey your strong work ethic and commitment to delivering exceptional results. Discuss your willingness to work independently and as part of a team, as well as your ability to handle multiple tasks effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Set-Up, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Set-Up positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.