Feeling lost in a sea of interview questions? Landed that dream interview for Machine Setter Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Machine Setter Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

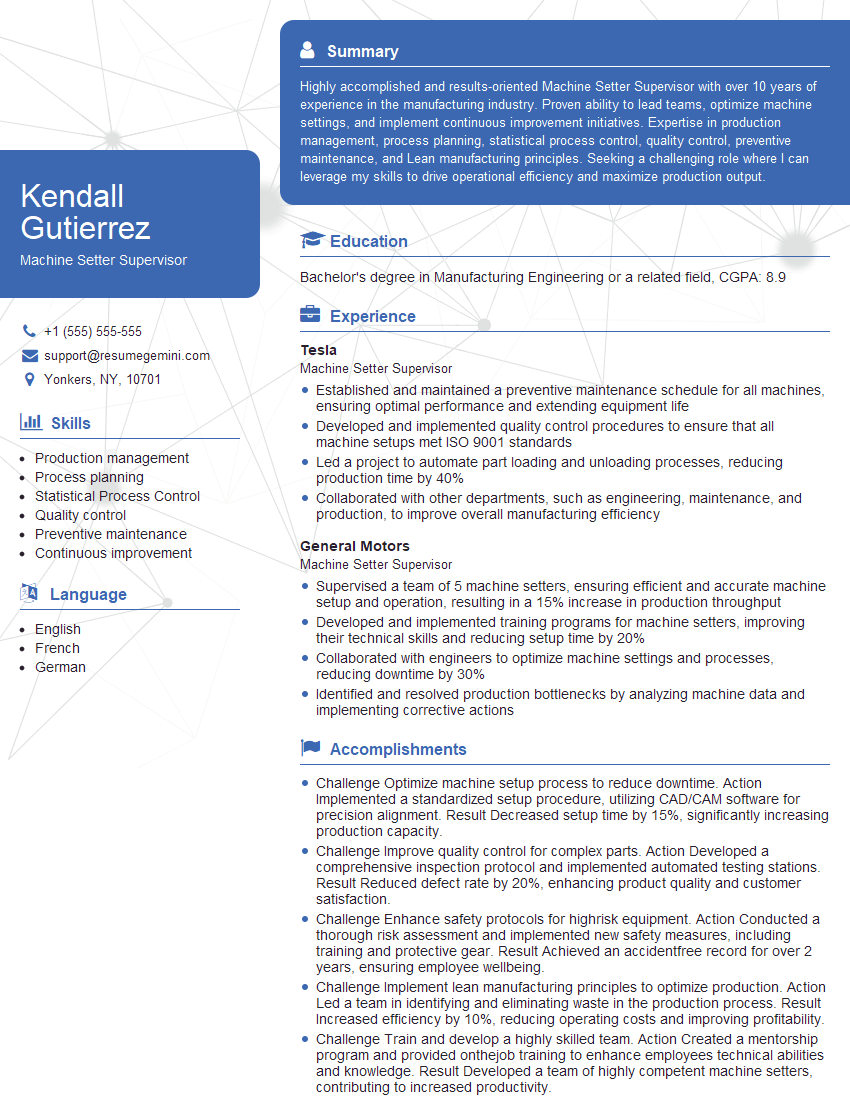

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Setter Supervisor

1. Describe the key responsibilities of a Machine Setter Supervisor.

As a Machine Setter Supervisor, my main responsibilities include:

- Supervising and leading a team of machine setters

- Ensuring that all machines are set up and operating correctly

- Troubleshooting and resolving any machine issues

- Monitoring production output and quality

- Training and developing team members

- Working with other departments to ensure smooth operations

2. What are the key technical skills required for this role?

The key technical skills required for this role include:

- Knowledge of machine tools and their operation

- Ability to read and interpret engineering drawings

- Experience with setting up and calibrating machines

- Knowledge of electrical systems and circuits

- Ability to troubleshoot and repair electrical problems

- Familiarity with CNC programming and software

- Ability to use data analysis tools

Mechanical skills:

Electrical skills:

Computer skills:

3. How do you ensure that machines are set up and operating correctly?

To ensure that machines are set up and operating correctly, I follow a systematic approach that includes:

- Reviewing the production schedule and work orders

- Inspecting the machine and its components

- Setting up the machine according to engineering specifications

- Calibrating the machine and verifying its accuracy

- Running test parts to ensure that the machine is producing quality products

- Documenting all settings and adjustments

4. How do you troubleshoot and resolve machine issues?

When troubleshooting machine issues, I use a logical and methodical approach that includes:

- Identifying the symptoms of the problem

- Inspecting the machine and its components

- Analyzing data from sensors and monitoring systems

- Consulting with maintenance personnel or engineers

- Testing and implementing potential solutions

- Documenting the problem and its resolution

5. How do you monitor production output and quality?

I monitor production output and quality through a combination of methods, including:

- Setting and tracking production targets

- Using data analysis tools to identify trends and patterns

- Performing regular inspections of products

- Receiving feedback from customers and internal stakeholders

- Implementing continuous improvement initiatives

6. How do you train and develop team members?

I am committed to developing my team members and helping them reach their full potential. My approach to training and development includes:

- Identifying training needs through performance evaluations and observations

- Developing and delivering training programs that are tailored to individual needs

- Providing on-the-job training and support

- Creating opportunities for team members to shadow experienced colleagues

- Encouraging team members to participate in professional development activities

7. How do you work with other departments to ensure smooth operations?

Collaboration is essential for the smooth operation of any organization. I work closely with other departments to ensure that all aspects of production are aligned and efficient. This includes:

- Communicating with production planning to coordinate schedules and materials

- Working with maintenance to ensure that machines are in good working order

- Collaborating with quality control to ensure that products meet specifications

- Interacting with sales and customer service to address customer needs

8. What are some of the challenges you have faced in your previous role as a Machine Setter Supervisor, and how did you overcome them?

One of the key challenges I faced was a decrease in production output due to machine downtime. To address this, I implemented a preventive maintenance program that involved regular inspections and servicing of machines. This resulted in a significant reduction in downtime and an increase in productivity.

Another challenge was the need to improve product quality. I worked with the quality control team to identify the root causes of defects and implemented new processes and procedures to prevent them from occurring. This led to a reduction in scrap and improved customer satisfaction.

9. What are your career goals, and how does this role align with them?

My career goal is to become a Production Manager. This role aligns with my goals because it provides me with the opportunity to develop my leadership, management, and technical skills. I am confident that I can contribute to the success of your organization and grow professionally in this role.

10. Do you have any questions for me?

I would like to know more about the specific challenges and opportunities that I can expect in this role. I am also interested in learning about the company’s growth plans and how I can contribute to them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Setter Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Setter Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Machine Setter Supervisor is responsible for overseeing the setup and maintenance of manufacturing machines to ensure optimal performance and production efficiency. Their key responsibilities include:

1. Machine Setup and Maintenance

Setting up and configuring machines according to production schedules and specifications

- Scheduling and coordinating preventive maintenance tasks

- Troubleshooting and resolving machine malfunctions

- Calibrating and adjusting machines to ensure accuracy and precision

- Implementing continuous improvement programs to enhance machine efficiency

2. Production Supervision

Monitoring and controlling production processes to meet quality and quantity targets

- Ensuring adherence to safety regulations and production standards

- Optimizing production lines to maximize output and minimize downtime

- Identifying and addressing production bottlenecks and inefficiencies

- Training and mentoring machine operators

3. Team Management

Leading and motivating a team of machine setters to achieve productivity goals

- Providing clear instructions and guidance to team members

- Delegating tasks and responsibilities effectively

- Monitoring performance and providing feedback

- Maintaining a positive and collaborative work environment

- Resolving conflicts and fostering teamwork

4. Quality Control

Ensuring that products meet quality standards by implementing quality control procedures

- Inspecting finished products for defects

- Analyzing production data to identify quality trends

- Implementing corrective actions to improve quality

- Working closely with quality assurance teams

Interview Tips

To ace the interview for a Machine Setter Supervisor position, candidates should prepare thoroughly and showcase their relevant skills and experience. Here are some tips to help them succeed:

1. Research the Company and Position

Candidates should thoroughly research the company, its industry, and the specific Machine Setter Supervisor role. This will enable them to tailor their answers to the company’s needs and demonstrate their understanding of the position’s responsibilities.

- Visit the company’s website and LinkedIn page

- Read industry-related publications and articles

- Connect with current or former employees on LinkedIn

2. Quantify Accomplishments

Candidates should use specific metrics and data to quantify their accomplishments and demonstrate their impact on previous roles. This will help the interviewer understand the tangible results they have achieved.

- Use numbers and percentages to highlight performance

- Provide examples of how they improved machine efficiency or reduced downtime

- Describe how they have successfully implemented quality control measures

3. Highlight Leadership and Communication Skills

Effective Machine Setter Supervisors must possess strong leadership and communication skills to lead and motivate their team. Candidates should provide examples of their ability to motivate, delegate, and resolve conflicts.

- Describe how they have successfully led and mentored teams

- Provide examples of how they have effectively communicated with team members

- Highlight their conflict resolution and problem-solving skills

4. Technical Expertise

Candidates should demonstrate their technical expertise in machine setup, maintenance, and troubleshooting. They should also have a strong understanding of quality control procedures and best practices.

- Describe their experience with different types of manufacturing machines

- Provide examples of how they have successfully diagnosed and resolved machine issues

- Highlight their knowledge of quality control methods and standards

5. Continuous Improvement Mindset

The role of a Machine Setter Supervisor often involves identifying and implementing continuous improvement initiatives. Candidates should demonstrate their commitment to continuous learning and improvement.

- Describe their experience with process improvement methodologies

- Provide examples of how they have successfully implemented improvements in previous roles

- Express their enthusiasm for learning new technologies and best practices

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Setter Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!