Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Shop Pantograph Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

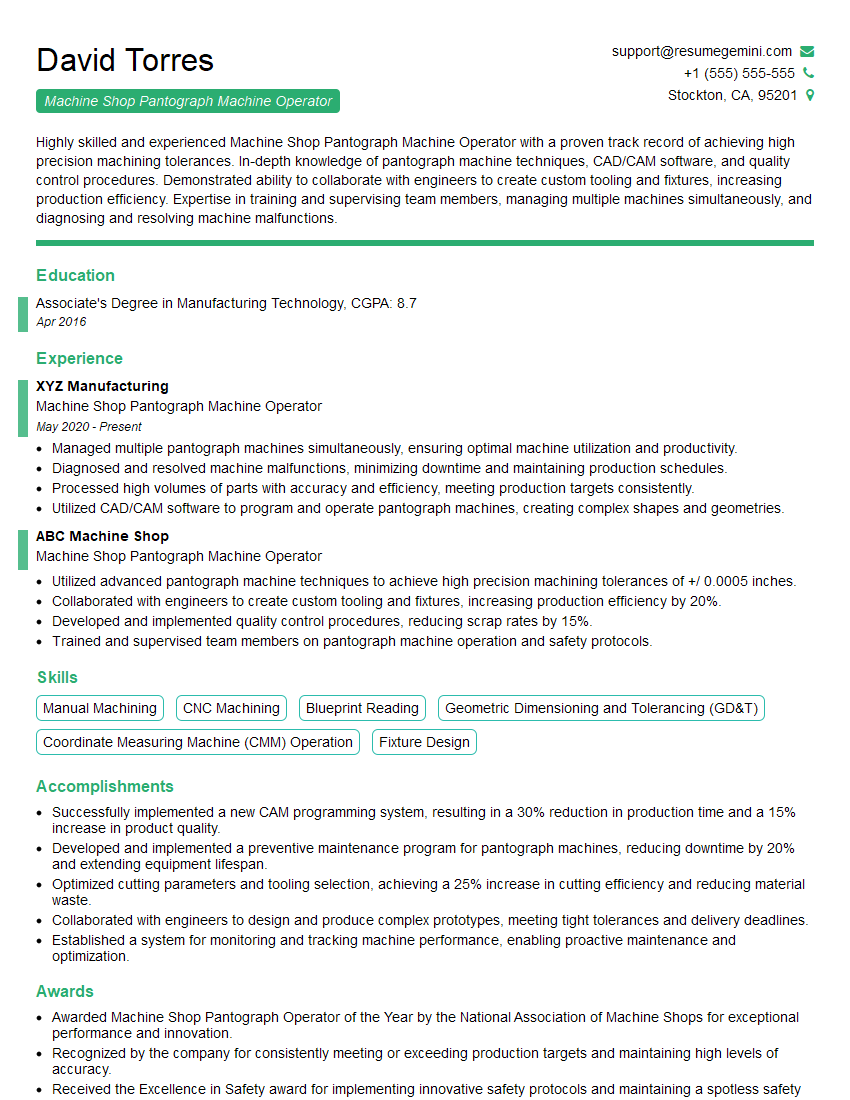

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Shop Pantograph Machine Operator

1. What are the key differences between a manual and a CNC pantograph machine?

A manual pantograph is operated manually, while a CNC pantograph is operated by a computer. Manual pantographs are less precise and less efficient than CNC pantographs, but they are also less expensive. CNC pantographs are more precise and more efficient than manual pantographs, but they are also more expensive.

- Manual pantographs are operated manually, while CNC pantographs are operated by a computer.

- Manual pantographs are less precise and less efficient than CNC pantographs.

- CNC pantographs are more precise and more efficient than manual pantographs.

- Manual pantographs are less expensive than CNC pantographs.

- CNC pantographs are more expensive than manual pantographs.

2. What are the different types of pantographs?

Engraving Pantographs

- Use a stylus to trace a pattern onto a surface.

- Can be used to engrave metal, wood, plastic, and other materials.

Duplicating Pantographs

- Use a stylus to trace a pattern onto a surface and then use a cutting tool to cut out the pattern.

- Can be used to duplicate keys, jewelry, and other objects.

Routing Pantographs

- Use a rotating cutting tool to cut out a pattern from a surface.

- Can be used to cut out shapes from wood, metal, and other materials.

3. What are the different types of materials that can be cut with a pantograph machine?

The type of materials that can be cut with a pantograph machine depends on the type of cutting tool that is used. Some common materials that can be cut with a pantograph machine include:

- Wood

- Metal

- Plastic

- Acrylic

- Foam

4. What are the safety precautions that should be taken when operating a pantograph machine?

The following safety precautions should be taken when operating a pantograph machine:

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep your hands and fingers away from the moving parts of the machine.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Make sure that the machine is properly grounded.

- Follow all of the manufacturer’s instructions for operating the machine.

5. What are the different types of maintenance that should be performed on a pantograph machine?

The following types of maintenance should be performed on a pantograph machine:

- Daily maintenance: This includes cleaning the machine, lubricating the moving parts, and checking the tightness of all of the bolts and screws.

- Weekly maintenance: This includes checking the alignment of the machine, inspecting the cutting tools, and cleaning the filters.

- Monthly maintenance: This includes checking the electrical system, inspecting the bearings, and replacing any worn or damaged parts.

6. What are the different types of troubleshooting that can be performed on a pantograph machine?

The following types of troubleshooting can be performed on a pantograph machine:

- Checking the power supply.

- Checking the fuses.

- Checking the wiring.

- Checking the motor.

- Checking the cutting tools.

- Checking the alignment of the machine.

7. What are the different types of software that can be used to operate a pantograph machine?

The following types of software can be used to operate a pantograph machine:

- CAD/CAM software

- Raster-to-vector software

- Machine control software

8. What are the different types of applications that a pantograph machine can be used for?

The following types of applications can be used for a pantograph machine:

- Engraving

- Duplicating

- Routing

- Milling

- Drilling

9. What are the different types of industries that use pantograph machines?

The following types of industries use pantograph machines:

- Automotive

- Aerospace

- Medical

- Electronics

- Jewelry

10. What are the different types of certifications that are available for pantograph machine operators?

The following types of certifications are available for pantograph machine operators:

- Certified Pantograph Machine Operator (CPMO)

- Certified Master Pantograph Machine Operator (CMPMO)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Shop Pantograph Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Shop Pantograph Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Shop Pantograph Machine Operators are responsible for a range of tasks that contribute to the efficiency and quality of production in a machine shop. Their primary duty is to operate pantograph machines to create precision parts and components.

1. Machine Operation and Maintenance

The operator’s primary responsibility is to operate thepantograph machine, which is a versatile machine used for cutting, engraving, or milling operations. They must be able to set up and operate the machine according to specifications, including adjusting the cutting speed, depth of cut, and other parameters.

- Set up and operate pantograph machine.

- Monitor machine during operation to ensure proper functioning.

- Perform routine maintenance on the machine, including cleaning, lubrication, and minor repairs.

2. Material Handling and Inspection

The operator is also responsible for handling the materials used in the production process. This includes loading and unloading the machine with raw materials and finished parts. They also ensure that the materials meet the specified requirements and inspect the finished products for quality.

- Load and unload raw materials and finished parts from the machine.

- Inspect materials to ensure they meet specifications.

- Inspect finished products for defects or errors.

3. Production Planning and Scheduling

The operator may also be involved in production planning and scheduling. This includes working with other team members to plan the production process, ensuring that materials and equipment are available and that production goals are met.

- Participate in production planning and scheduling.

- Coordinate with other team members to ensure smooth production flow.

- Monitor production progress and identify potential issues.

4. Safety and Housekeeping

The operator must adhere to safety regulations and maintain a clean and organized work area. This includes wearing appropriate safety gear and keeping the machine and surrounding area free from debris and hazards.

- Follow safety regulations and wear appropriate safety gear.

- Maintain a clean and organized work area.

- Report any safety concerns or hazards to supervisors.

Interview Tips

Preparing for an interview for a Machine Shop Pantograph Machine Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and the specific requirements of the role.

- Visit the company website to learn about their history, products, and services.

- Check out the company’s social media pages to get a sense of their culture.

- Read the job description carefully and identify the key skills and experience required.

2. Highlight Relevant Experience and Skills

During the interview, be sure to highlight your relevant experience and skills that relate to the job requirements. This may include your experience operating pantograph machines, your knowledge of materials and manufacturing processes, and your ability to work in a team environment.

- Quantify your accomplishments and provide specific examples to demonstrate your skills.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Be prepared to discuss your experience with different types of materials and manufacturing processes.

3. Demonstrate Your Safety Awareness

As a Machine Shop Pantograph Machine Operator, safety is a top priority. Be prepared to demonstrate your awareness of safety regulations and your commitment to following safety protocols. This may include your experience with lockout/tagout procedures, your knowledge of emergency procedures, and your ability to identify and report safety hazards.

- Describe your experience with lockout/tagout procedures and other safety protocols.

- Discuss your knowledge of emergency procedures and your ability to respond to emergencies.

- Explain how you would identify and report safety hazards.

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the position and the company. This is also an opportunity to clarify any information or ask about the company’s culture and values.

- Ask about the company’s growth plans and future goals.

- Inquire about the company’s commitment to training and development.

- Ask about the opportunity for advancement within the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Shop Pantograph Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.