Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Sizer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

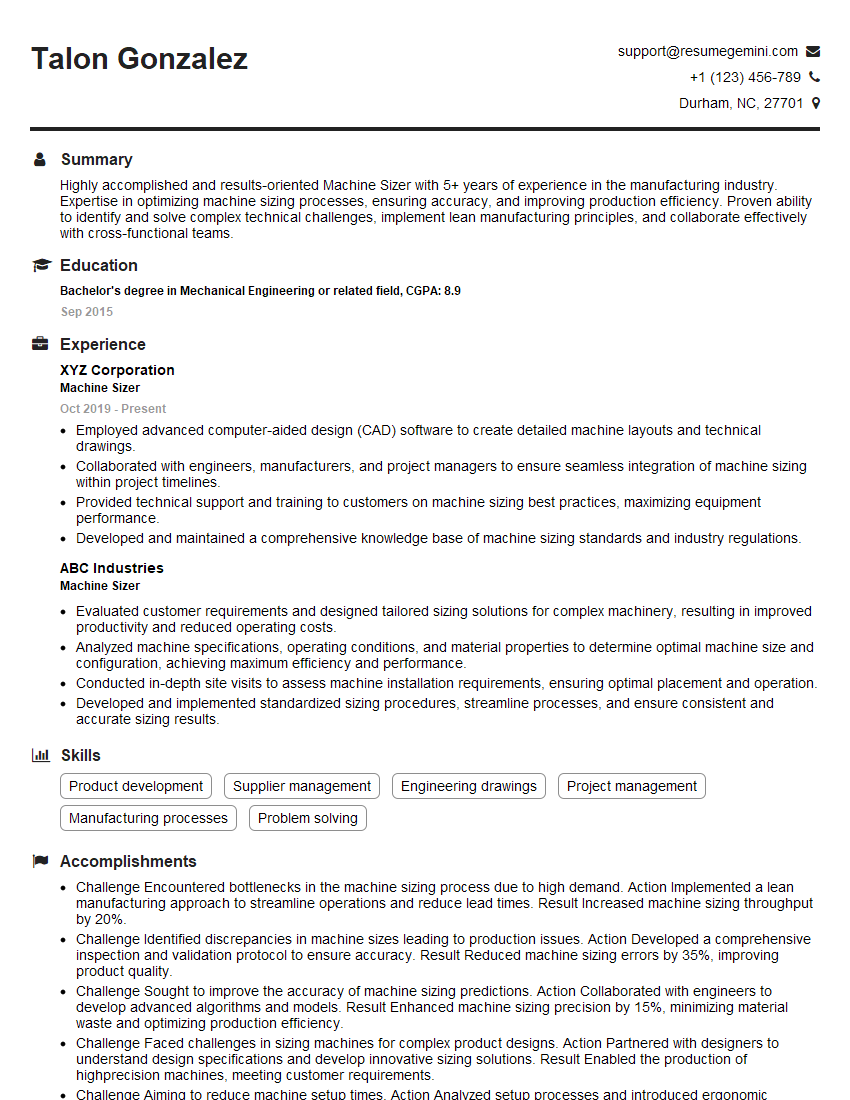

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Sizer

1. What are the key responsibilities of a Machine Sizer?

The key responsibilities of a Machine Sizer include:

- Determining the optimal size and capacity of machines and equipment for production lines and manufacturing facilities.

- Analyzing production data, equipment capabilities, and process flow to make informed recommendations.

- Ensuring that machines and equipment are sized appropriately to meet production goals and minimize downtime.

- Working with engineers and production managers to design and implement machine sizing solutions.

- Monitoring machine performance and making adjustments as needed to maintain optimal efficiency.

2. What factors do you consider when sizing machines?

Equipment capabilities

- The capabilities of the equipment, including its speed, accuracy, and capacity.

- The type of materials that the equipment will be processing.

- The desired production output.

Process flow

- The flow of materials through the production process.

- The layout of the production facility.

- The availability of space and resources.

3. What are the different types of sizing methods?

The different types of sizing methods include:

- Deterministic sizing: This method uses mathematical models and historical data to determine the optimal size of machines.

- Simulation sizing: This method uses computer simulations to model the production process and determine the optimal size of machines.

- Heuristic sizing: This method uses rules of thumb and expert knowledge to determine the optimal size of machines.

4. What are the advantages and disadvantages of each sizing method?

The advantages and disadvantages of each sizing method are as follows:

Deterministic sizing

- Advantages: This method is relatively simple and straightforward to use.

- Disadvantages: This method can be inaccurate if the mathematical models and historical data are not reliable.

Simulation sizing

- Advantages: This method can be very accurate if the simulation model is well-developed.

- Disadvantages: This method can be time-consuming and expensive to use.

Heuristic sizing

- Advantages: This method is quick and inexpensive to use.

- Disadvantages: This method can be inaccurate if the rules of thumb and expert knowledge are not reliable.

5. What are the common mistakes that are made when sizing machines?

The common mistakes that are made when sizing machines include:

- Not considering all of the factors that affect machine size.

- Using the wrong sizing method.

- Not taking into account the future needs of the production process.

- Not considering the cost of the machines.

6. What are the consequences of sizing machines incorrectly?

The consequences of sizing machines incorrectly can include:

- Reduced production output.

- Increased downtime.

- Higher operating costs.

- Safety hazards.

7. What are the latest trends in machine sizing?

The latest trends in machine sizing include:

- The use of artificial intelligence (AI) and machine learning (ML) to optimize machine sizing.

- The development of new sizing methods that are more accurate and reliable.

- The increasing use of simulation sizing to model the production process and determine the optimal size of machines.

8. What are the challenges of machine sizing in the future?

The challenges of machine sizing in the future include:

- The increasing complexity of production processes.

- The need for greater accuracy and reliability in machine sizing.

- The need to reduce the cost of machine sizing.

9. How do you stay up-to-date on the latest trends and developments in machine sizing?

I stay up-to-date on the latest trends and developments in machine sizing by:

- Reading industry publications and attending conferences.

- Participating in online forums and discussion groups.

- Conducting research on new sizing methods and technologies.

10. What is your favorite part of being a Machine Sizer?

My favorite part of being a Machine Sizer is the challenge of finding the optimal size of machines for production processes. I enjoy using my knowledge and skills to help companies improve their efficiency and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Sizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Sizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Machine Sizer

The Machine Sizer is responsible for determining the appropriate size and type of machine for a given manufacturing process. This involves analyzing the production requirements, material properties, and available resources. The Machine Sizer also works closely with other departments to ensure that the selected machine meets the overall production goals.

1. Production Requirements Analysis

The Machine Sizer analyzes the production requirements for the manufacturing process. This includes the required production volume, cycle time, and quality standards. The Machine Sizer also evaluates the material properties of the product being manufactured, the available resources, and the budget constraints.

2. Machine Selection

Based on the production requirements analysis, the Machine Sizer selects the appropriate machine for the manufacturing process. This may involve researching different machine types, comparing their specifications, and consulting with manufacturers and vendors. The Machine Sizer also considers the cost, maintenance, and environmental impact of the machine.

3. Machine Installation and Setup

The Machine Sizer coordinates the installation and setup of the selected machine. This may involve working with engineering, maintenance, and production personnel. The Machine Sizer also ensures that the machine is properly calibrated and tested before it is put into operation.

4. Ongoing Monitoring and Evaluation

The Machine Sizer monitors the performance of the machine on an ongoing basis. This may involve collecting data on production output, cycle time, and quality. The Machine Sizer also conducts regular inspections and maintenance checks to ensure that the machine is operating at peak efficiency.

Interview Preparation Tips for a Machine Sizer

Preparing for a Machine Sizer interview can be challenging, but there are a few tips that can help you increase your chances of success.

1. Research the company and position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You should also be familiar with the specific requirements of the position you are applying for.

2. Practice your answers to common interview questions

There are a few common interview questions that you can expect in a Machine Sizer interview. These questions may include:

- Tell me about a time when you had to analyze a complex problem and come up with a solution.

- How do you stay up to date on the latest trends in machine sizing technology?

- What are your thoughts on the future of machine sizing?

3. Be prepared to talk about your experience

The interviewer will be interested in your experience in machine sizing. Be sure to highlight your skills and accomplishments, and be prepared to provide specific examples of your work.

4. Be professional and enthusiastic

First impressions matter, so be sure to dress professionally and arrive on time for your interview. Be friendly and enthusiastic, and be prepared to answer questions about your qualifications and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Sizer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.