Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Skiver interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Skiver so you can tailor your answers to impress potential employers.

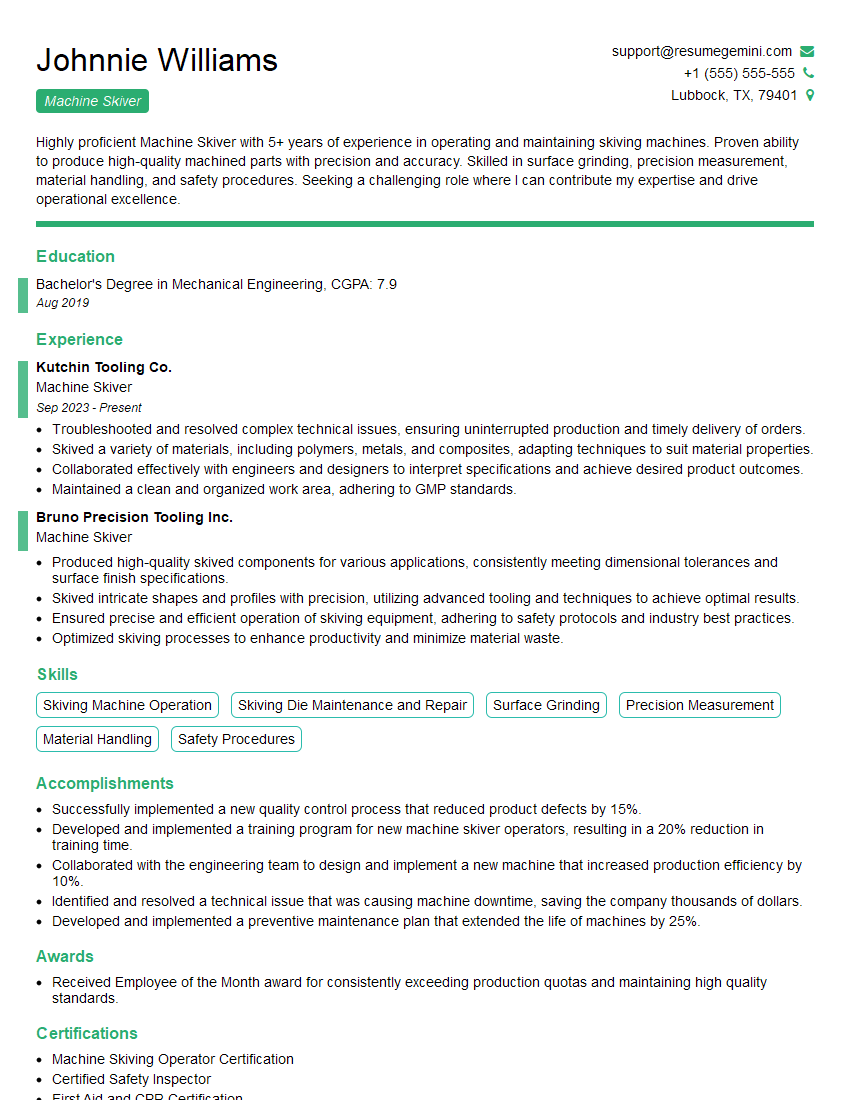

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Skiver

1. Describe the process of machine skiving in detail, highlighting the key steps and materials involved.

Machine skiving is a process of cutting and thinning leather or other materials using a specialized machine. The process involves several key steps and materials:

- Preparing the material: The leather or other material is prepared by removing any excess or uneven edges and ensuring it is properly conditioned for cutting.

- Positioning the material on the skiving machine: The material is carefully positioned on the machine’s cutting table and secured using clamps or other fixtures.

- Adjusting the cutting blade: The cutting blade is adjusted to the desired thickness and angle for the desired skiving effect.

- Operating the machine: The machine is operated to move the cutting blade across the material, thinning it to the required specifications.

- Inspecting the finished product: The finished product is inspected to ensure it meets the desired thickness and quality standards.

2. What are the different types of blades used in machine skiving, and when would you choose a particular type?

Types of Blades:

- Straight blades: Used for straight cuts and creating clean edges.

- Curved blades: Used for curved cuts and creating specific shapes.

- Bevelled blades: Used for creating a beveled edge on the material.

Choosing a Blade:

- Thickness of material: Thicker materials require blades with a larger cutting angle.

- Desired edge shape: The shape of the blade determines the shape of the finished edge.

- Material composition: Different materials may require specific blade materials or coatings for optimal performance.

3. How do you determine the optimal cutting speed and pressure for machine skiving a particular material?

- Material characteristics: Different materials have different cutting properties, such as hardness, flexibility, and grain direction.

- Desired finish: The desired surface finish of the skived material influences the cutting parameters.

- Machine capabilities: The capabilities of the machine, such as spindle speed and torque, limit the range of cutting parameters.

- Experimentation and experience: Trial and error, as well as experience with different materials, helps determine the optimal settings.

4. What are the common troubleshooting techniques for addressing issues with machine skiving, such as uneven cuts, rough edges, or material tearing?

- Uneven cuts: Check blade sharpness, ensure proper material positioning, and adjust cutting pressure.

- Rough edges: Use a finer blade, adjust cutting speed, or apply a lubricant to reduce friction.

- Material tearing: Reduce cutting pressure, use a sharper blade, or change the cutting direction.

- Other issues: Check machine calibration, inspect material for defects, and ensure proper maintenance of the machine.

5. How do you ensure the safety of operators when working with machine skiving equipment?

- Proper training: Operators must receive thorough training on machine operation and safety procedures.

- Personal protective equipment (PPE): Safety glasses, gloves, and appropriate clothing should be worn.

- Machine guards: Ensure all machine guards and safety features are in place and functional.

- Regular maintenance: Regular inspection and maintenance of the machine help prevent malfunctions and potential hazards.

- Emergency procedures: Establish clear emergency procedures and ensure operators are familiar with them.

6. How do you maintain and calibrate machine skiving equipment to ensure optimal performance?

- Regular cleaning: Remove dust, debris, and lubricant buildup from the machine to maintain accuracy.

- Blade maintenance: Inspect and sharpen blades regularly to ensure clean and precise cuts.

- Calibration: Check and adjust the machine’s cutting angle, blade alignment, and pressure settings to maintain consistency.

- Lubrication: Lubricate moving parts according to manufacturer’s recommendations to minimize friction and wear.

- Troubleshooting: Promptly identify and resolve any issues that arise to prevent further damage or downtime.

7. Describe the different types of leather suitable for machine skiving and how the choice of leather affects the finished product.

Suitable Leather Types:

- Full-grain leather: Durable and high-quality, provides a smooth and even surface for skiving.

- Top-grain leather: Similar to full-grain but has a sanded or buffed surface, resulting in a more consistent appearance.

- Split leather: Made from the lower layers of the hide, less durable but more flexible and cost-effective.

Impact on Finished Product:

- Texture: The grain and texture of the leather influence the surface finish of the skived material.

- Thickness: Different leather thicknesses require adjustments in cutting parameters to achieve the desired results.

- Strength: Full-grain leather provides the highest strength, while split leather has lower tensile strength.

8. Discuss the advantages and disadvantages of using a CNC-controlled machine skiving system compared to manual skiving.

Advantages of CNC Skiving:

- Precision and consistency: CNC systems ensure precise cutting with consistent results, eliminating human error and variability.

- Efficiency: Automated processes increase production speed and reduce labor costs.

- Complex shapes: CNC machines can handle intricate cuts and shapes that are difficult to achieve manually.

Disadvantages of CNC Skiving:

- Cost: CNC systems are generally more expensive than manual machines.

- Flexibility: Manual skiving offers more flexibility for quick adjustments and small-batch production.

- Skill requirement: CNC operators require specialized training and programming knowledge.

9. How do you optimize the skiving process for specific applications, considering factors such as material thickness, desired edge profile, and production volume?

- Material thickness: Adjust cutting parameters, such as blade angle and pressure, based on the thickness of the material.

- Edge profile: Choose the appropriate blade type and cutting angle to achieve the desired edge shape.

- Production volume: For high-volume production, consider using CNC skiving systems or optimizing machine settings for speed and efficiency.

- Special considerations: Factor in any specific requirements, such as skiving multiple layers or creating complex shapes.

10. Describe the advancements in machine skiving technology and how they have improved the efficiency and quality of the process.

- Computer-aided design (CAD): CAD software allows for precise design and optimization of skiving patterns, reducing setup time and material waste.

- Laser-guided cutting: Laser technology enables highly accurate and intricate cuts, improving edge quality and reducing operator dependency.

- Automated blade changing: Automated blade changing systems reduce downtime and improve productivity in high-volume operations.

- Real-time monitoring: Sensors and monitoring systems provide real-time data on machine performance, allowing for quick adjustments and preventive maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Skiver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Skiver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Skivers are responsible for the operation, setup and maintenance of machine skiving equipments in a production environment.

1. Machine Operation

intro paragraph

- Operate and monitor machine skiving equipments to produce leather or fabric components.

- Ensure that machine setups are correct and meet specifications for each job.

2. Setup and Adjustments

intro paragraph

- Set up and adjust machine skiving equipment according to job specifications.

- Inspect setup parameters and materials to ensure proper operation and quality.

3. Maintenance and Troubleshooting

intro paragraph

- Perform routine maintenance on machine skiving equipment, including cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve equipment malfunctions, ensuring timely resolution to minimize downtime.

4. Quality Control

intro paragraph

- Inspect and measure skived components to ensure they meet specifications.

- Identify and correct any deviations from quality standards.

Interview Tips

Interviewing for a Machine Skiver position requires preparation and showcasing your skills and experience to stand out from other candidates. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and the specific requirements of the Machine Skiver role. This demonstrates your interest and enthusiasm for the position.

- Visit the company’s website and social media pages to learn about their culture and values.

- Review the job description thoroughly to identify key responsibilities and qualifications.

Example: “I have thoroughly reviewed your company’s website and was impressed by your commitment to sustainable manufacturing. As a Machine Skiver with a passion for precision and quality, I am confident that I can contribute to your team’s success.”

2. Highlight Your Technical Expertise

Emphasize your technical skills and experience in operating, setting up, and maintaining machine skiving equipment. Provide specific examples to demonstrate your proficiency.

- Quantify your accomplishments, such as “Increased production efficiency by 15% through optimized machine setup and maintenance procedures.”

- Describe your experience in troubleshooting and resolving equipment malfunctions, highlighting your problem-solving abilities.

Example: “In my previous role, I was responsible for operating and maintaining a fleet of machine skiving equipment. I consistently exceeded production targets while ensuring the highest quality standards.

3. Showcase Your Quality-Centric Approach

Machine Skivers play a crucial role in ensuring product quality. Emphasize your attention to detail, commitment to precision, and ability to identify and correct quality deviations.

- Explain your experience in implementing quality control measures, such as inspection procedures and statistical process control.

- Highlight your ability to work independently and as part of a team to maintain high quality standards.

Example: “I have a keen eye for detail and a deep understanding of quality control principles. In my previous role, I was instrumental in reducing product defects by 20% through rigorous inspection and corrective action implementation.”

4. Prepare for Common Interview Questions

Research common interview questions for Machine Skivers and prepare thoughtful answers that showcase your strengths and qualifications. Some common questions include:

- “Describe your experience in setting up and operating machine skiving equipment.”

- “How do you ensure the accuracy and precision of skived components?”

- “What are your strategies for troubleshooting and resolving equipment malfunctions?”

- “How do you prioritize quality control in your work?”

Example: “When setting up machine skiving equipment, I meticulously follow manufacturer specifications and conduct thorough inspections to ensure optimal performance and accuracy.”

Next Step:

Now that you’re armed with the knowledge of Machine Skiver interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Skiver positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini