Are you gearing up for a career in Machine Sprayer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Sprayer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

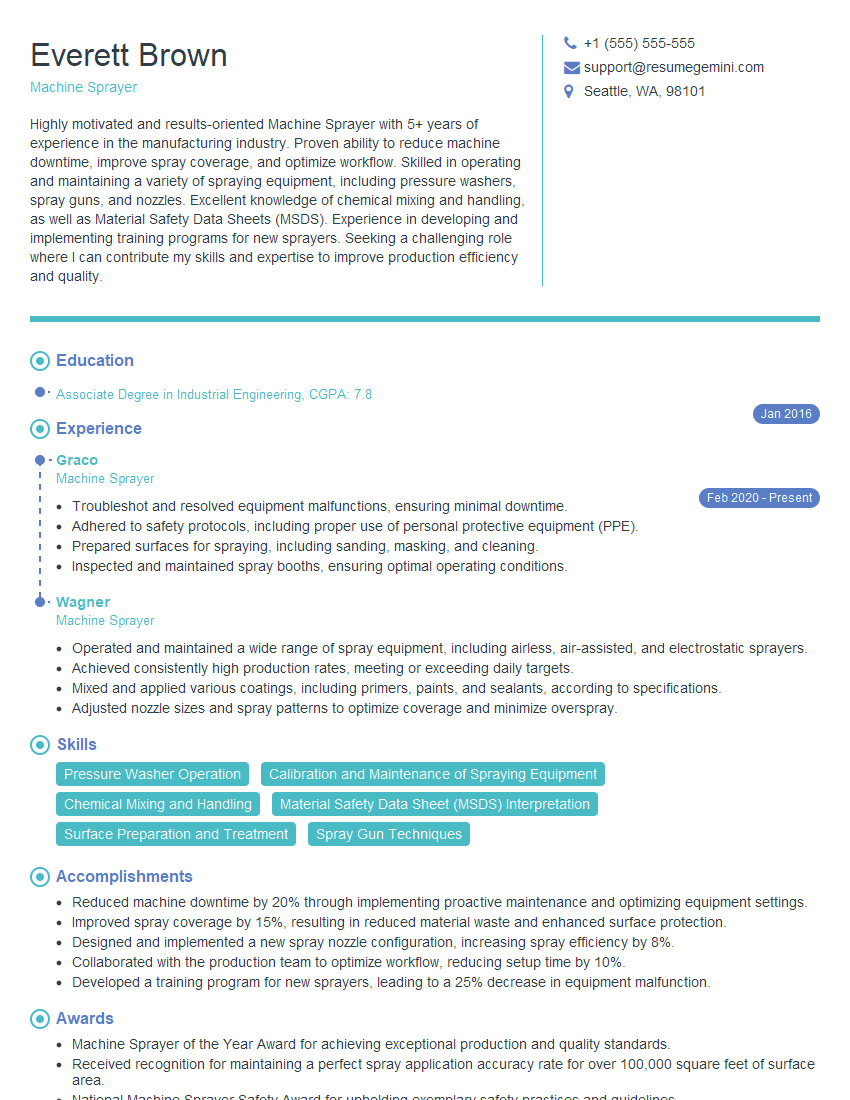

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Sprayer

1. What are the different types of machine sprayers, and what are their key features?

- Airblast sprayer: Uses a high-velocity air stream to carry the spray droplets to the target.

- Centrifugal sprayer: Uses a rotating impeller to generate a centrifugal force that disperses the spray droplets.

- Hydraulic sprayer: Uses a pump to create pressure that forces the spray droplets through nozzles.

- Electrostatic sprayer: Uses an electrostatic charge to attract the spray droplets to the target, reducing drift.

2. How do you calibrate a machine sprayer to ensure accurate application rates?

Calibration Steps:

- Determine the desired spray rate based on the label instructions.

- Measure the output of the sprayer per minute using a graduated cylinder.

- Adjust the sprayer settings (e.g., pump pressure, nozzle size) until the desired spray rate is achieved.

- Test the calibration on a small area to verify accuracy.

Considerations:

- Use clean water for calibration.

- Wear appropriate safety gear.

- Consider environmental conditions (e.g., wind speed, temperature) when calibrating.

3. Describe the nozzle types used in machine sprayers and their respective applications?

- Flat fan nozzle: Wide, flat spray pattern suitable for broadcast spraying.

- TeeJet nozzle: Variable spray pattern that can be adjusted from flat fan to cone.

- Flood jet nozzle: Produces a wide, flooding spray pattern for covering large areas.

- Cone nozzle: Narrower spray pattern for targeted applications.

- Drift reduction nozzle: Designed to minimize spray drift by producing larger droplets.

4. How do you clean and maintain a machine sprayer to prevent corrosion and ensure optimal performance?

- Rinse the sprayer with clean water after each use: Remove pesticide residues and prevent corrosion.

- Perform a thorough cleaning every few months: Use a sprayer cleaner or detergent to remove stubborn deposits.

- Lubricate moving parts regularly: Extend the life of the sprayer and prevent wear.

- Check nozzles for wear or damage: Replace nozzles as needed to maintain spray accuracy.

- Store the sprayer in a dry, sheltered location: Protect it from moisture and extreme temperatures.

5. How can you troubleshoot common problems associated with machine sprayers, such as clogging or uneven spray patterns?

- Clogging: Check for clogged filters, nozzles, or pump inlets; clean or replace as needed.

- Uneven spray patterns: Inspect nozzles for damage or wear; adjust nozzle settings if necessary.

- Low pressure: Check for leaks in the hose or pump; tighten connections or replace faulty components.

- Overspray: Reduce spray pressure or use nozzles with a smaller orifice size.

- Underspray: Increase spray pressure or use nozzles with a larger orifice size.

6. What safety precautions should be taken when operating a machine sprayer to minimize exposure to pesticides and other hazards?

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, respirator.

- Mix and apply pesticides according to the label instructions.

- Avoid spraying in windy or rainy conditions.

- Use a closed transfer system to minimize exposure to concentrates.

- Dispose of pesticide containers and unused chemicals properly.

7. How do you determine the appropriate application rate and timing for different types of pesticides and crops?

- Read the pesticide label: It provides specific information on application rates and timing.

- Consult with an agricultural advisor: They can provide tailored recommendations based on the crop and pest situation.

- Monitor crop health: Apply pesticides only when necessary to avoid over-treatment.

- Consider environmental conditions: Adjust application rates and timing based on factors like temperature and precipitation.

8. Explain how you would calibrate a pH meter to ensure accuracy and reliability of readings?

- Obtain pH buffers: These are solutions with known pH values.

- Turn on the pH meter: Allow it to stabilize.

- Immerse the probe into the first buffer: Typically pH 7.

- Adjust the calibration knob: Until the display matches the known pH value.

- Rinse the probe: With distilled water.

- Immerse the probe into the second buffer: Typically pH 4 or 10.

- Adjust the slope knob: Until the display matches the known pH value.

- Rinse the probe: And store it in storage solution.

9. Describe the different types of nozzles used in machine sprayers, and explain how their choice affects the spray pattern and application efficiency?

- Flat fan nozzles: Produce a wide, flat spray pattern suitable for broadcast spraying.

- Cone nozzles: Produce a narrow, focused spray pattern for targeted applications.

- Flood jet nozzles: Produce a wide, flooding spray pattern for covering large areas.

- Drift reduction nozzles: Designed to minimize spray drift by producing larger droplets.

- Air induction nozzles: Use air to atomize the spray droplets, resulting in improved coverage and penetration.

10. Explain how you would adjust the boom height of a machine sprayer to ensure proper coverage and minimize spray drift?

- Determine the target crop height: Measure the height of the crop to be sprayed.

- Set the boom height: Adjust the boom to a height that is slightly above the crop canopy.

- Inspect the spray pattern: Check that the spray is reaching the target crop but not drifting beyond it.

- Make adjustments: Raise or lower the boom as needed to optimize coverage and minimize drift.

- Consider environmental conditions: Wind speed and direction can affect drift; adjust boom height accordingly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Sprayers are responsible for the safe and efficient operation of spraying equipment to apply protective coatings, such as paint, sealants, or pesticides, onto various surfaces. Their key responsibilities include:

1. Equipment Operation

Operating and maintaining spraying equipment, including airless, air-assisted, and electrostatic sprayers.

- Selecting the appropriate spray nozzle and adjusting the flow rate, pressure, and pattern.

- Troubleshooting and repairing minor equipment malfunctions.

2. Surface Preparation

Preparing surfaces for spraying, including cleaning, masking, and sanding.

- Ensuring that surfaces are free of debris, dust, and contaminants.

- Applying primers and undercoats as necessary.

3. Spraying Techniques

Using proper spraying techniques to achieve uniform coverage and desired finish.

- Controlling spray distance and angle to prevent overspray or missed areas.

- Adjusting spray patterns and settings to accommodate different surfaces and materials.

4. Safety and Environmental Compliance

Adhering to safety regulations and environmental standards during spraying operations.

- Wearing appropriate personal protective equipment (PPE), such as respirators and gloves.

- Following proper disposal procedures for waste materials and spent solvents.

Interview Tips

Preparing for a Machine Sprayer interview requires a combination of technical knowledge, practical skills, and a strong understanding of safety protocols. Consider the following tips to enhance your chances of success:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. Familiarize yourself with their industry, products, and company culture. This knowledge will demonstrate your interest and preparation during the interview.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on relevant trends and technologies.

2. Practice Your Spraying Techniques

Highlight your practical skills by practicing spraying techniques and demonstrating your knowledge of different spray equipment. If possible, set up a mock spraying station to showcase your abilities.

- Demonstrate proper handling and operation of spray guns and equipment.

- Explain the factors that influence spray quality, such as nozzle selection, pressure adjustments, and environmental conditions.

3. Emphasize Safety and Compliance

Emphasize your commitment to safety and compliance by highlighting your knowledge of relevant regulations and best practices. Discuss your experience in using PPE, handling hazardous materials, and following proper disposal procedures.

- Explain your understanding of OSHA regulations and industry standards related to spraying operations.

- Provide examples of your proactive approach to safety, such as identifying potential hazards and implementing preventive measures.

4. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and solve problems that may arise during spraying operations. Prepare examples of situations where you successfully identified and resolved equipment issues or achieved desired results despite unexpected challenges.

- Describe a time when you diagnosed and repaired a malfunctioning spray gun.

- Explain how you handled a situation where you encountered unexpected surface conditions and adjusted your spraying approach accordingly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Sprayer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!