Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Spreader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

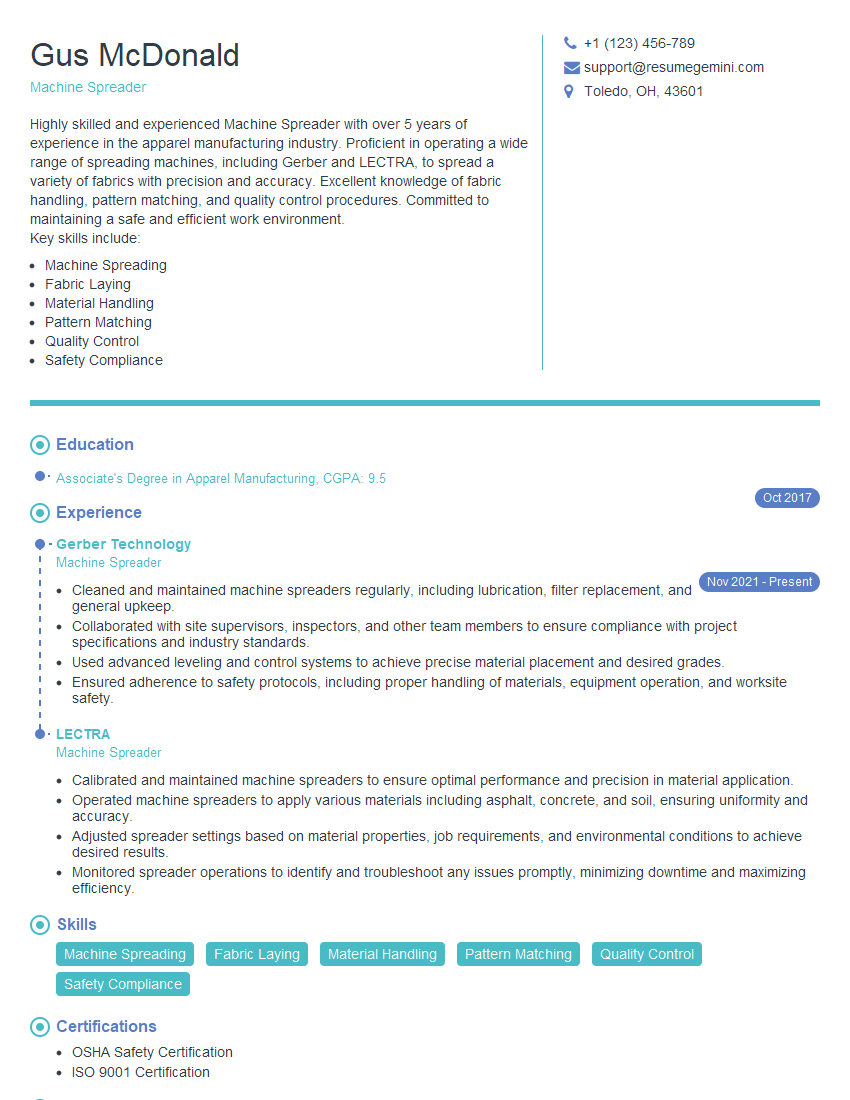

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Spreader

1. What are the main factors to consider when choosing a machine spreader?

When selecting a machine spreader, several important factors must be considered to ensure optimal performance and compatibility with the application:

- Material properties: The type of material being spread, including its size, shape, and density, influences the spreader’s design and capacity.

- Application requirements: The specific purpose and desired output of the spreading operation, such as the required spread pattern, accuracy, and rate.

- Operating environment: The terrain and weather conditions where the spreader will be used, along with any potential obstacles or hazards.

- Spreader capacity and range: The required material flow rate, spreading width, and maximum distance for effective distribution.

- Safety features: Ensuring the spreader meets all necessary safety regulations and incorporates features to minimize risks to operators and the surrounding environment.

2. What is the difference between a volumetric and a gravimetric machine spreader?

Volumetric spreader

- Measures material volume to determine the spread rate.

- Relies on calibrated augers or belts to control the flow.

- Prone to inaccuracies due to material density variations.

Gravimetric spreader

- Measures material weight to ensure accurate spread rates.

- Uses load cells or weigh bridges to monitor material flow.

- Provides consistent and precise application, even with varying material densities.

3. Describe the calibration process for a machine spreader.

Calibrating a machine spreader involves ensuring the accuracy of its material application rate:

- Check spreader settings: Confirm that the spreader is correctly configured for the material and application requirements.

- Collect material samples: Obtain representative samples of the material to be spread and determine its bulk density.

- Set material parameters: Input the material’s bulk density and target spread rate into the spreader’s controller.

- Perform test runs: Spread a known weight of material over a measured distance and compare the actual spread rate to the desired rate.

- Adjust and fine-tune: Make necessary adjustments to the spreader settings or material parameters until the desired spread rate is achieved.

4. How do you troubleshoot common problems encountered with machine spreaders?

- Uneven spread pattern: Inspect spreader components for damage or wear, verify calibration, and adjust material flow settings.

- Clogging: Check for obstructions in the hopper, conveyor system, or spread mechanism; clear any blockages and ensure proper material flow.

- Material bridging: Use anti-bridging agents or vibrators to prevent material from forming clumps and blocking the hopper.

- Inaccurate spread rate: Recalibrate the spreader, check sensors and load cells for proper functioning, and adjust material parameters.

- Defective components: Inspect and replace worn or damaged parts such as belts, augers, or spread vanes.

5. What are the safety precautions to observe when operating a machine spreader?

- Follow manufacturer’s instructions: Read and understand the spreader’s operating manual thoroughly.

- Wear appropriate PPE: Use safety glasses, gloves, and protective clothing to minimize exposure to materials and debris.

- Inspect the spreader regularly: Check for any damage or malfunctions before each use.

- Be aware of surroundings: Pay attention to the work area, potential hazards, and the movement of other equipment.

- Never operate the spreader near flammable materials: Keep a safe distance from sources of ignition to prevent fires.

6. Describe the different types of spread patterns produced by machine spreaders and their applications.

- Centerline spread: Material is distributed in a narrow band or line directly behind the spreader, suitable for precise applications like seed planting.

- Broadcast spread: Material is spread over a wide area, creating a uniform coverage, ideal for applying fertilizers or soil amendments.

- Side spread: Material is spread to one side of the spreader, useful for applications along roadsides or field edges.

- Variable rate spread: The spreader can adjust the spread rate based on GPS or sensor data, allowing for site-specific applications and optimizing resource usage.

7. How do you ensure the accuracy of spread rates when using a machine spreader?

- Proper calibration: Calibrate the spreader regularly according to the manufacturer’s instructions.

- Optimal material conditions: Ensure the material is dry, free-flowing, and consistent in density.

- Controlled operating speed: Maintain a steady speed to ensure proper material flow and spread rate.

- Load cell monitoring: Use load cells or weigh bridges to monitor material flow and make adjustments as needed.

- GPS guidance: Integrate GPS technology with the spreader to ensure accurate spread patterns and application rates.

8. How do you optimize the performance of a machine spreader?

- Regular maintenance: Perform scheduled maintenance to keep the spreader in good working condition.

- Material handling: Ensure proper storage and handling of materials to prevent moisture or contamination.

- Operator training: Train operators on proper spreader use, calibration, and troubleshooting techniques.

- Environmental factors: Consider wind speed and direction, terrain conditions, and temperature to adjust spreader settings accordingly.

- Data analysis: Use data from spread pattern analysis or yield monitors to identify areas for improvement and optimize spreader performance.

9. Describe the role of technology in modern machine spreaders.

- Precision control: GPS and sensor integration allows for precise spread patterns and variable rate applications.

- Data logging and analysis: Spreaders equipped with data logging capabilities provide valuable insights into application performance.

- Remote monitoring: Remote monitoring systems enable real-time tracking of spreader operations and adjustments.

- Automated calibration: Some spreaders feature automated calibration systems for faster and more accurate setup.

- User-friendly interfaces: Advanced user interfaces make spreaders easier to operate and configure.

10. How do you stay updated on the latest advancements in machine spreader technology?

- Industry events: Attend trade shows and conferences to learn about new products and developments.

- Manufacturer’s literature: Read technical brochures and white papers from spreader manufacturers.

- Online resources: Utilize online forums, industry magazines, and websites to access up-to-date information.

- Networking: Connect with industry professionals and experts to exchange knowledge and insights.

- Continuing education: Participate in workshops or training programs to enhance your understanding of spreader technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Spreader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Spreader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Machine Spreader plays a pivotal role in the construction and maintenance of roads and other paved surfaces.

1. Equipment Handling and Operation

Skilled operation of machine spreaders, including calibration and adjustment for optimal material distribution and compaction.

- Adhering to specified material spread rates, ensuring proper application and coverage.

- Maintaining and troubleshooting equipment to prevent breakdowns and ensure efficient operation.

2. Quality Control and Assurance

Monitoring and maintaining the quality of the asphalt spread, ensuring it meets specifications and industry standards.

- Conducting regular inspections of the spread material, identifying and correcting any irregularities.

- Collaborating with other team members to ensure adherence to quality control procedures.

3. Safety and Compliance

Prioritizing safety on the job site, following established safety protocols and regulations.

- Wearing appropriate personal protective equipment (PPE) and ensuring a safe work environment.

- Understanding and adhering to environmental regulations related to asphalt spreading activities.

4. Communication and Teamwork

Effective communication with supervisors, crew members, and clients to ensure smooth project execution.

- Reporting progress, equipment issues, and any potential delays to relevant parties.

- Collaborating with other team members to coordinate work schedules and ensure efficient resource allocation.

Interview Tips

Preparation is key to acing any job interview, and the Machine Spreader position is no exception. Here are a few tips to help you prepare and impress the hiring manager:

1. Research the Company and Position

Take the time to research the company you’re applying to, including their values, mission, and current projects.

- This will demonstrate your interest in the company and show that you’ve taken the time to learn about their business.

- Additionally, review the job description thoroughly to identify the key responsibilities and qualifications required for the position.

2. Highlight Your Equipment Expertise

Emphasize your proficiency in operating and maintaining machine spreaders.

- Provide specific examples of your experience, such as operating different types of spreaders or troubleshooting common equipment issues.

- Quantify your accomplishments whenever possible, such as the number of projects you’ve worked on or the percentage of downtime you’ve reduced.

3. Showcase Your Quality Consciousness

Demonstrate your commitment to quality by highlighting your experience in monitoring and maintaining the quality of asphalt spreads.

- Describe your understanding of industry standards and specifications, as well as your ability to identify and correct irregularities.

- Explain how you work with other team members to ensure that quality standards are consistently met.

4. Practice Your Communication Skills

Communication is crucial in any team environment. Emphasize your ability to communicate effectively with supervisors, crew members, and clients.

- Provide examples of situations where you successfully resolved conflicts or misunderstandings.

- Explain how you keep stakeholders informed of progress, issues, and potential delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Spreader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Spreader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.