Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Spring Former interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Spring Former so you can tailor your answers to impress potential employers.

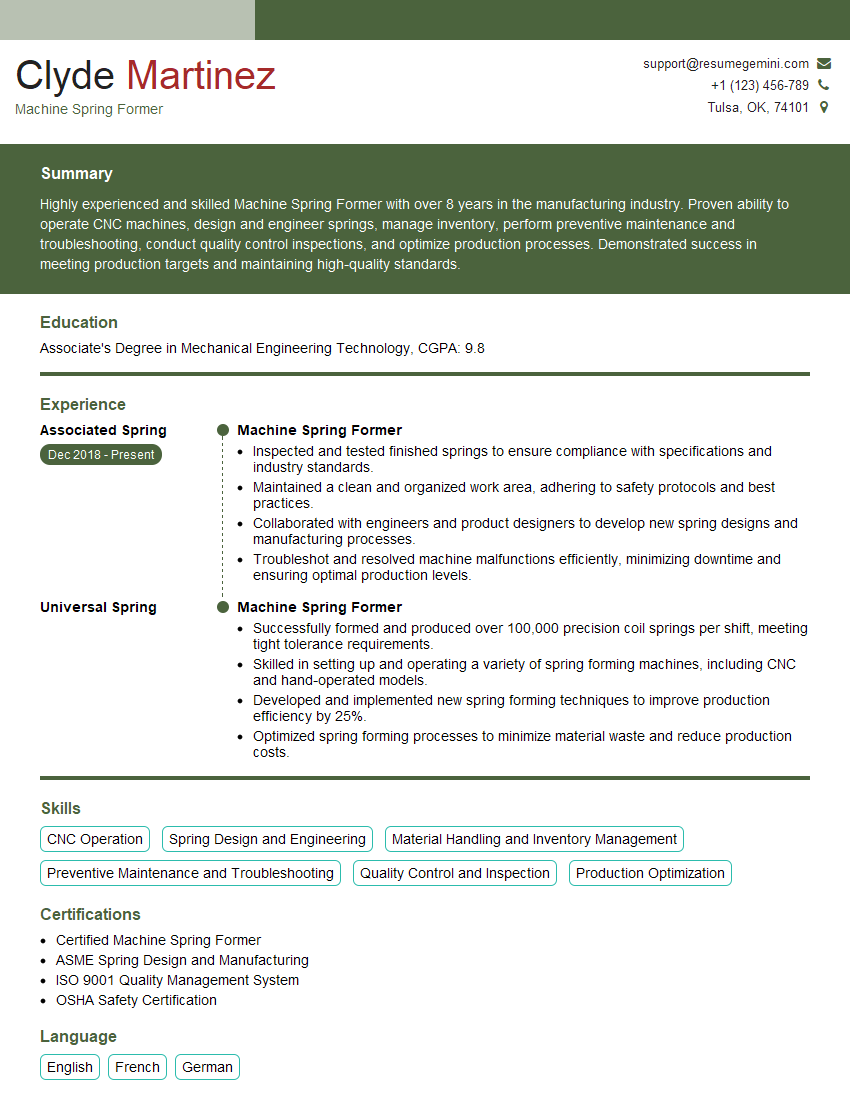

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Spring Former

1. Explain the process of setting up a machine spring former?

Here is a breakdown of the process of setting up a machine spring former:

- Load the wire into the machine. The wire is typically fed into the machine from a coil. The diameter of the wire will determine the size of the spring.

- Set the machine’s parameters. These parameters include the spring’s diameter, pitch, and length. The machine’s settings will also determine the speed at which the spring is formed.

- Start the machine. The machine will automatically form the spring according to the settings that have been entered.

- Inspect the spring. Once the spring has been formed, it should be inspected to ensure that it meets the desired specifications.

2. What are the different types of machine spring formers?

There are two main types of machine spring formers:

- Horizontal spring formers are used to form springs that are relatively long and have a small diameter.

- Vertical spring formers are used to form springs that are relatively short and have a large diameter.

3. How do you troubleshoot a machine spring former?

There are a number of things that can go wrong with a machine spring former. Some of the most common problems include:

- The wire is not feeding properly. This can be caused by a number of factors, such as the wire being too thick or too thin, or the tension on the wire being too high or too low.

- The spring is not being formed correctly. This can be caused by a number of factors, such as the machine’s settings being incorrect, or the machine being out of alignment.

- The spring is breaking. This can be caused by a number of factors, such as the wire being too weak, or the spring being formed too quickly.

4. What are the safety precautions that should be taken when operating a machine spring former?

There are a number of safety precautions that should be taken when operating a machine spring former, including:

- Wear appropriate safety gear. This includes safety glasses, gloves, and earplugs.

- Keep the work area clean and free of clutter. This will help to prevent accidents.

- Do not operate the machine if you are not trained to do so. Machine spring formers can be dangerous if they are not operated properly.

5. What is the difference between a spring and a coil?

A spring is a mechanical device that stores energy when it is deformed. A coil is a type of spring that is formed by winding wire around a cylindrical or conical mandrel.

6. What are the different types of springs?

There are many different types of springs, but some of the most common include:

- Compression springs are designed to resist compressive forces.

- Extension springs are designed to resist tensile forces.

- Torsion springs are designed to resist rotational forces.

7. What are the factors that affect the performance of a spring?

There are a number of factors that affect the performance of a spring, including:

- The material of the spring. The material of the spring will determine its strength, stiffness, and durability.

- The size of the spring. The size of the spring will determine its load capacity and deflection.

- The shape of the spring. The shape of the spring will determine its natural frequency and damping characteristics.

8. How do you calculate the spring rate of a spring?

The spring rate of a spring is a measure of its stiffness. It is calculated by dividing the force required to compress or extend the spring by the amount of compression or extension.

9. What is the difference between a linear spring and a nonlinear spring?

A linear spring is a spring that has a constant spring rate. A nonlinear spring is a spring that has a spring rate that varies with the amount of compression or extension.

10. What are the applications of springs?

Springs are used in a wide variety of applications, including:

- Automotive suspensions

- Medical devices

- Industrial equipment

- Consumer products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Spring Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Spring Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Machine Spring Former

Machine Spring Formers are responsible for operating and maintaining specialized machinery used in the production of springs. Their primary duties include:

1. Machine Operation

- Setting up and calibrating spring forming machines according to production specifications.

- Loading and feeding wire or strip material into the machine and ensuring proper tension.

- Monitoring machine operation, making adjustments as needed to maintain production quality and efficiency.

2. Spring Production

- Producing a variety of spring shapes and sizes, meeting specific customer requirements.

- Inspecting completed springs for dimensional accuracy, surface finish, and other quality parameters.

- Packaging and labeling finished springs for storage or shipment.

3. Machine Maintenance

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Identifying potential machine issues and taking corrective actions to prevent breakdowns.

- Assisting in major repairs or overhauls as required.

4. Quality Control

- Adhering to established quality standards and procedures.

- Conducting visual inspections and using measuring equipment to verify spring dimensions and properties.

- Reporting any quality issues or deviations to supervisors for further investigation.

Interview Preparation Tips for Machine Spring Former Candidates

To ace an interview for a Machine Spring Former position, candidates should prepare effectively. Here are some crucial tips:

1. Research the Company and Role

- Visit the company website and social media pages to gather information about their business, products, and culture.

- Review the job description thoroughly and identify the key responsibilities and qualifications required for the role.

- Learn about the industry, including the latest trends and advancements in spring manufacturing.

2. Highlight Relevant Skills and Experience

- Quantify your accomplishments and provide specific examples of your skills in machine operation, spring production, and quality control.

- Showcase your knowledge of different types of spring forming machines and your ability to set them up efficiently.

- Emphasize your understanding of spring materials, design principles, and quality standards.

3. Practice Common Interview Questions

- Prepare answers to typical interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Rehearse technical questions related to machine spring forming, such as the types of springs you have worked with and your experience in troubleshooting machine malfunctions.

- Consider behavioral questions that assess your problem-solving abilities and teamwork skills.

4. Prepare Questions for the Interviewer

- Asking thoughtful questions at the end of the interview demonstrates your interest in the company and the role.

- Inquire about the company’s future plans, their approach to quality control, or any specific challenges related to the position.

- Avoid asking generic questions or those that can be easily found on the company website.

Next Step:

Now that you’re armed with the knowledge of Machine Spring Former interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Spring Former positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini