Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Stone Polisher Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

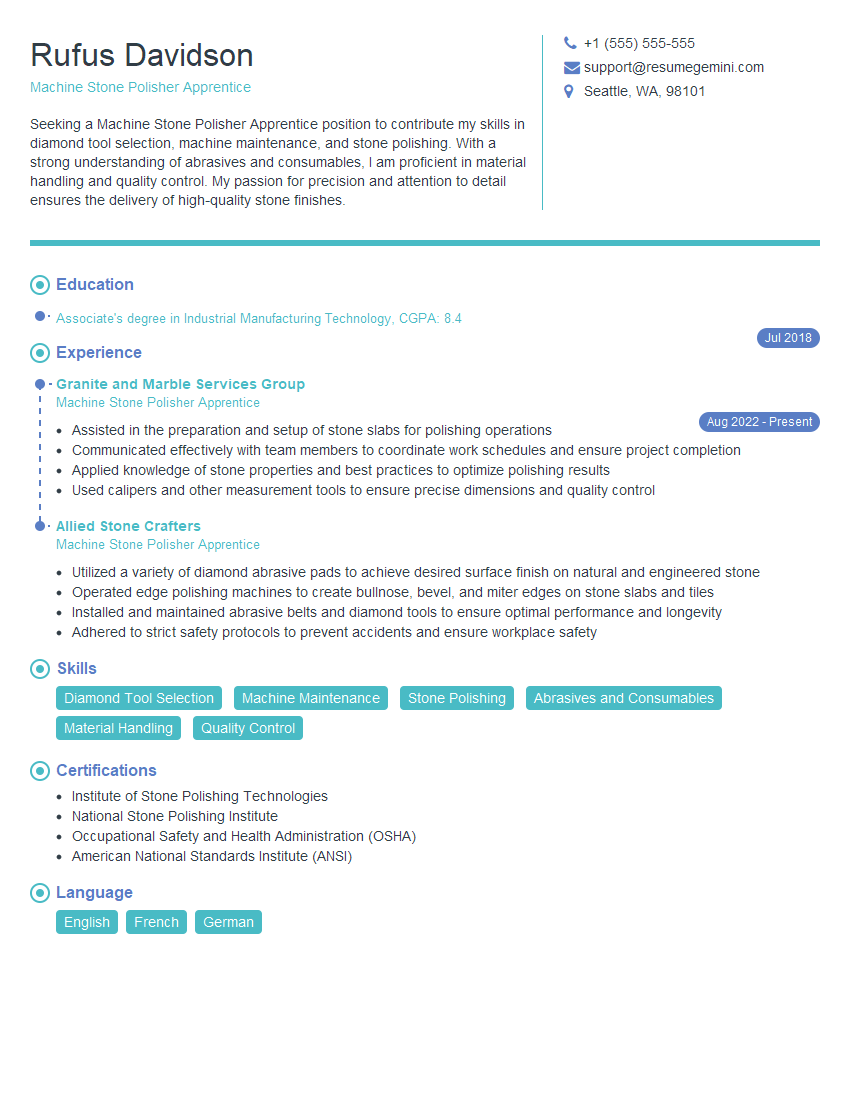

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Stone Polisher Apprentice

1. What are the different types of stone polishing machines and their uses?

- Edge polishing machines: Used for polishing the edges of stone slabs, creating a smooth and finished look.

- Surface polishing machines: Used for polishing the surface of stone slabs, removing imperfections and creating a glossy finish.

- Wet polishing machines: Use water as a lubricant during the polishing process, resulting in a smoother finish than dry polishing.

- Dry polishing machines: Do not use water during the polishing process, resulting in a faster but less smooth finish.

2. What are the safety precautions that need to be taken when operating a stone polishing machine?

- Wear appropriate safety gear: Including gloves, eye protection, and a dust mask.

- Inspect the machine before use: Ensure that all parts are in good working order.

- Secure the stone firmly: To prevent it from moving during the polishing process and causing injury.

- Use the correct polishing pads: For the type of stone being polished and the desired finish.

- Never put your hands or fingers near the polishing wheels: To avoid injury.

3. What are the different types of polishing pads used for stone polishing and their applications?

- Diamond pads: Used for coarse grinding and shaping of stone.

- Resin pads: Used for fine polishing and creating a glossy finish.

- Buffing pads: Used for final polishing and removing any imperfections.

- Felt pads: Used for buffing and polishing soft stones such as marble.

4. How do you determine the correct grit size of polishing pads to use for a particular stone?

- Consider the type of stone: Harder stones require finer grit pads, while softer stones can tolerate coarser grit pads.

- Assess the desired finish: A higher grit pad will produce a smoother finish than a lower grit pad.

- Test different grit sizes: Start with a lower grit pad and gradually increase the grit size until the desired finish is achieved.

5. What are the factors that affect the quality of the stone polishing process?

- Type of stone: Different stones have different hardness and porosity, which can affect the polishing process.

- Machine speed: Too high a speed can cause the stone to overheat and damage the finish, while too low a speed can result in a slow and inefficient polishing process.

- Pressure applied: Too much pressure can damage the stone, while too little pressure will result in an uneven finish.

- Coolant: Using water or other coolants during the polishing process helps to reduce heat buildup and improve the finish.

6. How do you troubleshoot common problems that may occur during stone polishing?

- Excessive vibration: Check the balance of the polishing machine, the tension of the belts, and the tightness of the bolts.

- Uneven polishing: Adjust the pressure applied, the machine speed, or the grit size of the polishing pads.

- Scratches on the stone: Use finer grit pads or adjust the machine speed and pressure to minimize scratching.

- Overheating of the stone: Use a coolant or reduce the machine speed and pressure.

7. How do you maintain a stone polishing machine to ensure its longevity and optimal performance?

- Regular cleaning: Remove dust and debris from the machine after each use.

- Inspection: Check for any loose or damaged parts and replace them as necessary.

- Lubrication: Lubricate moving parts to prevent wear and tear.

- Belt tension adjustment: Ensure that the belts are properly tensioned to prevent slippage.

8. What are the different types of stone finishes and how are they achieved?

- Honed finish: Achieved by using coarse grit pads, resulting in a matte and smooth surface.

- Polished finish: Achieved by using finer grit pads, resulting in a glossy and reflective surface.

- Brushed finish: Achieved by using a brush attachment on the polishing machine, resulting in a textured and rustic surface.

- Antiqued finish: Achieved by using a combination of different grit pads and hand tools, resulting in a distressed and aged appearance.

9. What is the difference between dry and wet stone polishing?

Dry polishing

- Does not use water or other coolants during the polishing process.

- Produces a faster finish but can result in a less smooth surface.

- Generates more dust and can be less effective on softer stones.

Wet polishing

- Uses water or other coolants during the polishing process.

- Produces a smoother finish and is more effective on softer stones.

- Generates less dust and helps to reduce heat buildup.

10. What are some tips for achieving a high-quality stone polished finish?

- Start with a coarse grit pad and gradually increase the grit size until the desired finish is achieved.

- Use a light and even pressure during the polishing process.

- Keep the stone surface clean and free of dust and debris.

- Use a coolant to reduce heat buildup and improve the finish.

- Inspect the stone regularly during the polishing process and make any necessary adjustments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Stone Polisher Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Stone Polisher Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Stone Polisher Apprentices have the responsibility of assisting machine stone polishers. They perform tasks that include operating and adjusting polishing machines to refine and finish stone surfaces. The job requires them to ensure that surfaces meet prescribed specifications for smoothness, texture, and dimensional accuracy. They work in collaboration with machine stone polishers, following instructions and learning the techniques of the trade.

1. Machine Operation and Maintenance

Apprentices are entrusted with the operation and maintenance of polishing machines. They are responsible for setting up, calibrating, and operating the equipment, ensuring that it functions smoothly and efficiently. Additionally, they perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs, to keep the machines in optimal working condition.

- Operate and adjust polishing machines to achieve desired surface finishes on stone

- Monitor machine performance and make necessary adjustments to ensure efficient operation

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs

2. Surface Preparation and Inspection

Apprentices are involved in preparing stone surfaces for polishing. They clean and smooth surfaces using abrasives, ensuring that they are free from imperfections. They also inspect polished surfaces to assess their quality, identifying and correcting any defects. This attention to detail ensures that the final finishes meet customer specifications.

- Clean and smooth stone surfaces using abrasives to prepare them for polishing

- Inspect polished surfaces for defects and make necessary corrections

- Verify that surfaces meet specifications for smoothness, texture, and dimensional accuracy

3. Material Handling and Storage

Apprentices are responsible for handling and storing stone materials safely and efficiently. They move and position stone slabs and blocks, using appropriate equipment and techniques to prevent damage. They also organize and maintain inventory, ensuring that materials are readily available for polishing operations.

- Move and position stone slabs and blocks using appropriate equipment and techniques

- Organize and maintain inventory of stone materials

- Ensure that materials are stored safely and securely

4. Safety and Environmental Compliance

Apprentices are committed to maintaining a safe and environmentally responsible work environment. They follow established safety protocols and wear appropriate protective gear while operating machinery. They also adhere to environmental regulations, ensuring that waste materials are disposed of properly and that the workplace is kept clean and organized.

- Follow established safety protocols and wear appropriate protective gear

- Adhere to environmental regulations and ensure proper disposal of waste materials

- Contribute to a clean and organized work environment

Interview Tips

To ace the interview for a Machine Stone Polisher Apprentice position, it is crucial to prepare thoroughly and present yourself professionally. Here are some helpful tips to guide your preparation.

1. Research the Company and Position

Take the time to research the company you are applying to and the specific position you are seeking. Learn about their history, values, and products or services. This will demonstrate your interest in the company and the role, and it will allow you to ask informed questions during the interview.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest developments

- Prepare questions that show you have researched the company and the position

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Focus on the key responsibilities of the apprentice position and how your qualifications match the company’s requirements. Provide specific examples of your work experience that demonstrate your abilities in machine operation, surface preparation, and material handling.

- Review the job description and identify the most important skills and qualifications

- Tailor your resume and cover letter to highlight these skills and qualifications

- Prepare to discuss your experience in detail during the interview

3. Demonstrate Your Passion and Enthusiasm

Convey your passion for the stone polishing trade and your eagerness to learn and grow. Show the interviewer that you are genuinely interested in the position and that you are excited about the opportunity to contribute to the company. Your enthusiasm will make you a more appealing candidate and increase your chances of success.

- Be prepared to share why you are interested in the stone polishing trade

- Explain what you find exciting about the position and the company

- Show that you are eager to learn and develop your skills

4. Ask Thoughtful Questions

Asking insightful questions during the interview demonstrates your interest in the position, the company, and the industry. Prepare a list of questions to ask the interviewer, focusing on areas that you are curious about or that you believe will provide valuable information. This will show that you are engaged in the conversation and that you are genuinely interested in the opportunity.

- Prepare a list of questions to ask the interviewer

- Focus on questions that show your interest in the position, the company, and the industry

- Ask questions that will provide you with valuable information

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Stone Polisher Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!